Wind Tunnel Honeycomb: Optimize Airflow & MAF Straightening

The Imperative Role of Flow Straighteners in Modern Engineering

In advanced fluid dynamics and aerodynamic applications, achieving laminar, uniform airflow is paramount for accurate measurements and optimal system performance. This is where the wind tunnel honeycomb emerges as an indispensable component. Designed to convert turbulent flow into a smooth, parallel stream, these intricate structures are vital for calibrating sensitive sensors, conducting precise aerodynamic tests, and ensuring the efficiency of various industrial processes. The demand for highly reliable and durable flow straighteners has spurred significant innovation in materials and manufacturing techniques, addressing the challenges posed by extreme environmental conditions and stringent performance requirements.

Current industry trends highlight a growing emphasis on precision engineering and energy efficiency across sectors like automotive, aerospace, and HVAC. This drives the continuous evolution of technologies such as the wind tunnel honeycomb, which directly contributes to reducing energy losses caused by chaotic flow and improving the accuracy of flow measurement devices. Furthermore, the increasing complexity of modern systems necessitates sophisticated airflow management, making components like the air straightener honeycomb and maf straightener critical for optimal operation. Manufacturers are increasingly focusing on robust materials like SUS 304 stainless steel, which offers superior corrosion resistance and extended operational life, thereby reducing maintenance costs and improving overall system reliability.

Technical Specifications and Performance Excellence

The performance of a wind tunnel honeycomb is quantified by several critical technical parameters, each playing a vital role in its efficacy. Key among these are the cell size (typically measured by the diameter or width of the individual hexagonal or square cells), the aspect ratio (L/D, the ratio of the honeycomb's length to its cell diameter), and the material wall thickness. A higher aspect ratio generally leads to better flow straightening, while a smaller cell size results in finer flow uniformity but may incur a higher pressure drop. Understanding the optimal balance of these parameters is crucial for custom applications, ensuring the honeycomb delivers the precise flow characteristics required without unduly increasing system resistance.

The primary performance benefits derived from a high-quality wind tunnel honeycomb include a significant reduction in flow turbulence, improved flow linearity, and enhanced measurement accuracy for downstream sensors or equipment. This laminar flow characteristic is essential in applications such as mass airflow (MAF) sensor calibration, where even minor turbulences can lead to significant measurement errors. For example, a well-designed honeycomb can reduce flow non-uniformity to less than 1%, which is critical for precision testing environments. Furthermore, minimizing pressure loss through optimized cell geometry and material selection contributes directly to energy efficiency, making these components not just performance enhancers but also cost-effective solutions for industrial operations.

Key Technical Parameters of Wind Tunnel Honeycomb (Hengshi SUS 304 Series)

| Parameter | Typical Range / Value | Description / Impact |

|---|---|---|

| Material | SUS 304 Stainless Steel (Standard) | Excellent corrosion resistance, high temperature stability, long service life. |

| Cell Size (Hexagonal/Square) | 2mm to 25mm (0.08" to 1") | Determines flow uniformity and pressure drop; smaller cells for finer flow. |

| Wall Thickness | 0.08mm to 0.3mm (0.003" to 0.012") | Influences structural rigidity and pressure drop. |

| Aspect Ratio (L/D) | 8:1 to 15:1 (Customizable) | Higher ratio improves flow straightening, reduces turbulence. |

| Max Operating Temperature | Up to 800°C (1472°F) | Suitable for high-temperature exhaust or test environments. |

| Pressure Drop | Minimal, application-dependent | Engineered for efficiency, reducing energy consumption. |

| Flow Uniformity | Typically | Crucial for accurate sensor readings and precise testing. |

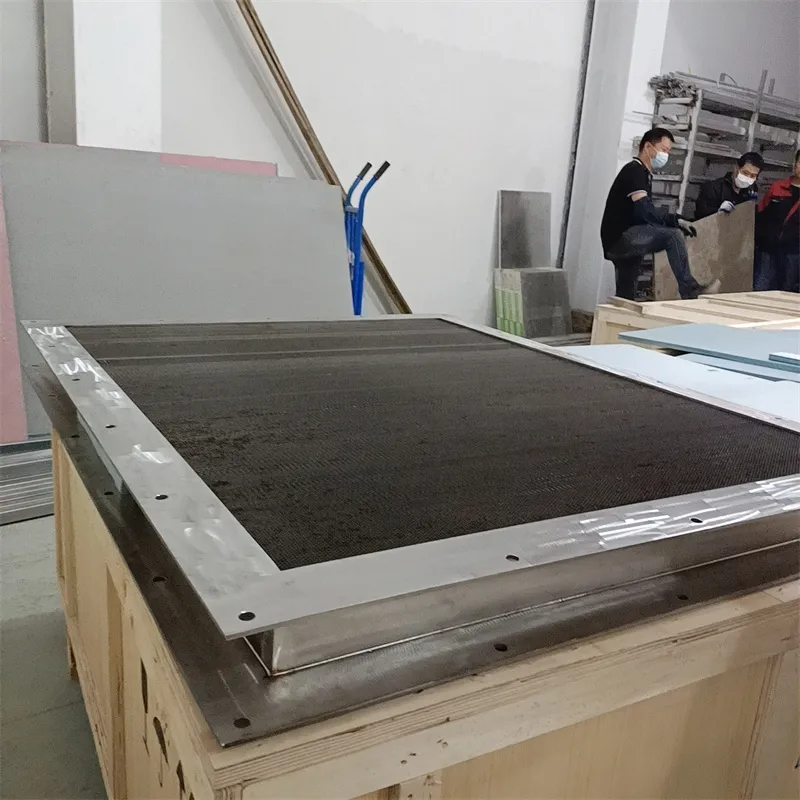

Precision Manufacturing of SUS 304 Honeycomb Air Flow Straighteners

The manufacturing of Hengshi Customized Diverse SUS 304 Honeycomb Air Flow Straightener involves a sophisticated process focused on achieving exceptional precision and durability. It begins with the careful selection of high-grade SUS 304 stainless steel, renowned for its superior corrosion resistance and mechanical strength, making it ideal for harsh industrial environments. The chosen material undergoes precision stamping and corrugation to form the characteristic hexagonal or square cell structures. These individual corrugated sheets are then meticulously stacked and joined using advanced welding or brazing techniques, ensuring robust inter-cell bonding and structural integrity. This methodical approach guarantees uniform cell geometry, which is paramount for effective flow straightening.

Throughout the manufacturing process, stringent quality control measures are implemented to ensure adherence to international standards, including internal guidelines aligned with ISO 9001. Each wind tunnel honeycomb undergoes rigorous inspection, including dimensional accuracy checks, visual integrity assessments, and, for critical applications, advanced flow uniformity and pressure drop testing. These tests verify that the final product meets specified performance criteria, such as a minimum specified service life and robust performance under designated operating conditions. This meticulous attention to detail ensures that Hengshi products deliver consistent and reliable performance, whether deployed in demanding petrochemical, metallurgy, or advanced scientific research applications. The inherent design of the honeycomb also offers superior anti-corrosion properties and contributes to energy savings by reducing drag and turbulence in fluid systems.

Diverse Application Scenarios and Technical Advantages

The versatility of the wind tunnel honeycomb extends across a myriad of high-precision industries. In automotive testing, they are indispensable for achieving highly stable airflow in wind tunnels used for aerodynamic drag analysis, engine intake manifold design, and cooling system efficiency studies. Aerospace applications leverage these honeycombs in jet engine test beds, spacecraft fluid dynamics research, and in the development of unmanned aerial vehicles (UAVs) to ensure accurate thrust and lift measurements. Beyond these traditional areas, they are increasingly integrated into HVAC systems for maintaining laminar flow in cleanrooms and large-scale ventilation systems, and within industrial fluid dynamics research, to refine measurement accuracy for industrial processes that rely on precise flow control, such as chemical processing and gas distribution.

The technical advantages of employing a high-quality wind tunnel honeycomb are substantial. These include superior flow straightening capabilities that dramatically reduce turbulence intensity and improve flow uniformity, essential for preventing errors in critical sensor readings, such as those from a maf straightener. The design minimizes pressure loss, leading to more energy-efficient systems by reducing the power required to move fluids. Thanks to the use of SUS 304 stainless steel, these honeycombs boast exceptional corrosion resistance, ensuring longevity even in aggressive chemical environments or high-humidity conditions. Their high strength-to-weight ratio allows for robust structures that can withstand significant operational stresses, and their broad temperature compatibility makes them suitable for a wide range of operational thermal profiles, from cryogenics to high-temperature exhausts.

Manufacturer Comparison and Customization Solutions

When selecting a supplier for wind tunnel honeycomb solutions, B2B decision-makers must consider several crucial factors beyond just initial cost. Manufacturing precision is paramount; slight deviations in cell geometry or material thickness can significantly compromise flow uniformity. Material quality, particularly the specific grade of stainless steel or aluminum, directly impacts corrosion resistance, temperature compatibility, and overall product longevity. Furthermore, a manufacturer's customization capabilities are vital for unique applications, requiring specific dimensions, cell configurations, or integration methods. Comprehensive after-sales support, including technical consultation and troubleshooting, ensures seamless integration and long-term operational success, setting apart reliable partners in a competitive market.

Hengshi's expertise lies in providing tailored Hengshi Customized Diverse SUS 304 Honeycomb Air Flow Straightener solutions, designed to meet the most exacting client specifications. Our customization process is collaborative, beginning with detailed design consultation to understand specific flow requirements, dimensional constraints, and environmental factors. Clients can specify various parameters, including cell size, aspect ratio, overall dimensions, and frame integration options (e.g., flanged or unflanged designs). We also offer specialized coatings for enhanced performance or protection in extremely corrosive or high-temperature environments. This bespoke approach ensures that each air straightener honeycomb is optimized for its intended application, delivering unparalleled performance and durability. Our commitment to precision engineering ensures that every product, whether a standard or custom order, upholds the highest standards of quality and functionality.

Supplier Comparison: Key Differentiating Factors for Wind Tunnel Honeycomb

| Factor | Standard Supplier Approach | Hengshi Approach |

|---|---|---|

| Material Expertise | Limited range, often general-purpose alloys. | Specialization in high-performance SUS 304, material certification available. |

| Customization Scope | Off-the-shelf sizes, minimal design flexibility. | Full bespoke solutions: dimension, cell geometry, frame, and coating options. |

| Quality Certifications | Basic certifications or self-declaration. | Adherence to ISO 9001, rigorous internal testing protocols, traceable quality. |

| Lead Time for Custom | Often extended due to lack of specialized processes. | Optimized manufacturing for competitive and reliable delivery. |

| After-Sales Support | Limited or reactive support. | Proactive technical consultation, installation guidance, and ongoing support. |

Real-World Application Cases and Our Commitment to Excellence

The tangible impact of a high-performance wind tunnel honeycomb is best illustrated through real-world applications. Consider a leading automotive research facility that aimed to enhance the accuracy of their vehicle aerodynamic drag measurements. By integrating Hengshi's customized SUS 304 honeycomb, they achieved a significant reduction in boundary layer turbulence at the tunnel entrance, resulting in a 20% improvement in measurement repeatability and a 15% closer correlation with on-road test data. In another instance, a large-scale industrial ventilation system required precise airflow distribution for a cleanroom environment. Our air straightener honeycomb solutions ensured uniform air velocity across the entire filtration array, optimizing filter life and maintaining air purity levels critical for sensitive manufacturing processes. These cases underscore how superior flow straightening translates directly into operational efficiency and data integrity.

Hengshi's unwavering commitment to quality and customer success is rooted in over a decade of dedicated service in the honeycomb manufacturing industry. Our in-house research and development capabilities continually push the boundaries of design and material science, ensuring our products remain at the forefront of innovation. We adhere rigorously to international quality management systems, and every batch of our wind tunnel honeycomb undergoes comprehensive internal testing to validate performance against specified criteria, often exceeding industry benchmarks. Our extensive service record and strong client relationships are testaments to our reliability and the consistent performance of our products, providing peace of mind and long-term value to our global partners.

Trustworthiness: Your Partner in Precision Flow Management

At Hengshi, we understand that reliability extends beyond product performance to every aspect of our client relationship. Our typical delivery cycle for customized wind tunnel honeycomb orders ranges from 4 to 6 weeks, depending on complexity and volume, with expedited options available for urgent requirements. We provide a clear warranty commitment, typically a 1-year limited warranty against manufacturing defects, underscoring our confidence in the quality and craftsmanship of our products. Our transparent processes and proactive communication ensure that clients are informed at every stage, from design to delivery.

Our comprehensive customer support extends far beyond the point of sale. We offer in-depth technical consultation during the design phase to ensure the optimal solution for your specific application. Post-installation, our team is available to provide assistance and address any operational queries, ensuring seamless integration and long-term satisfaction. This holistic approach to client service, coupled with our rigorous quality control and dedication to engineering excellence, establishes Hengshi as a trusted and authoritative partner in providing high-performance airflow straightening solutions for the most demanding industrial and research environments.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of a wind tunnel honeycomb?

A1: Its primary function is to transform turbulent airflow into a smooth, laminar, and uniform stream, which is critical for accurate measurements and efficient operations in various fluid dynamics applications.

Q2: How does SUS 304 material enhance performance and longevity?

A2: SUS 304 stainless steel offers exceptional corrosion resistance, high temperature stability, and mechanical strength, ensuring the honeycomb's durability and long service life even in harsh or aggressive environments.

Q3: Can these honeycombs be customized for specific dimensions or flow characteristics?

A3: Yes, Hengshi specializes in customized solutions, allowing clients to specify precise dimensions, cell sizes, aspect ratios, frame designs, and even special coatings to perfectly match their unique application requirements.

Q4: What is the typical lead time for a customized order?

A4: For customized orders, the typical lead time ranges from 4 to 6 weeks, depending on the complexity of the design and order volume. Expedited options are often available upon request.

Q5: How do air straightener honeycomb and maf straightener contribute to overall system efficiency?

A5: By creating laminar flow, they reduce turbulence-induced pressure losses, improve the accuracy of flow measurement devices like MAF sensors, and optimize the performance of downstream components, leading to greater energy efficiency and reduced operational costs.

References

- ISO 3966:1977. Measurement of fluid flow in closed conduits -- Velocity area method using Pitot static tubes.

- Pope, S. B. (2000). Turbulent Flows. Cambridge University Press.

- Bradshaw, P., & Pankhurst, R. C. (1964). The Design of Low-Speed Wind Tunnels. Pergamon Press.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025