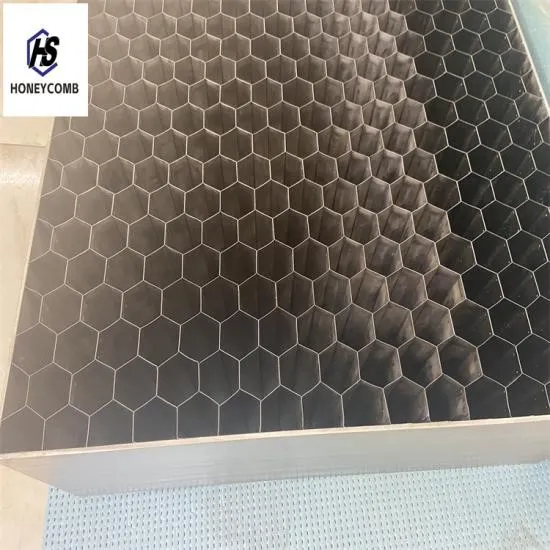

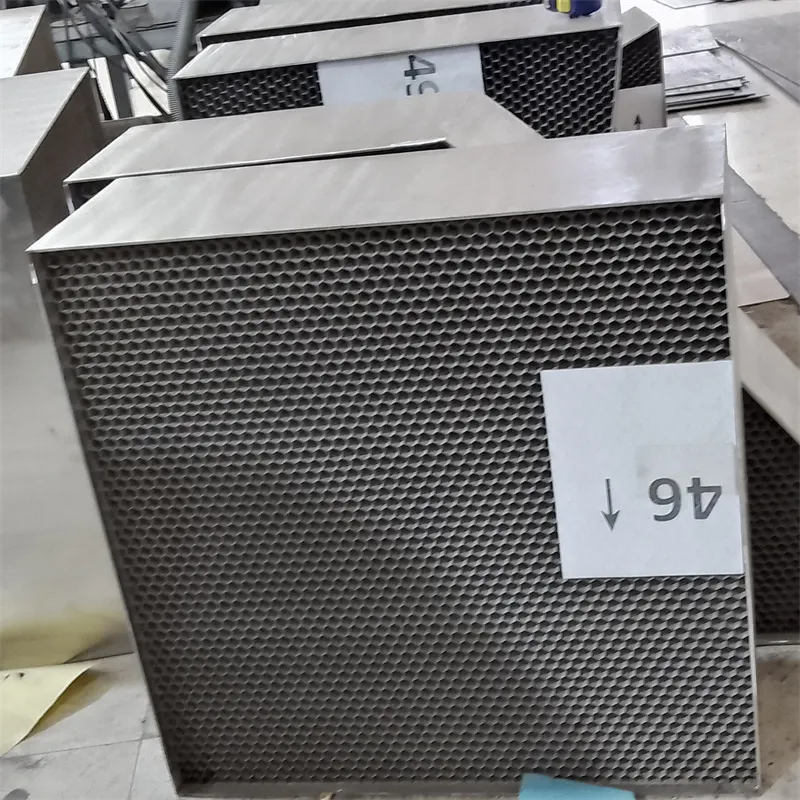

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

Metal honeycombs are revolutionizing industries by providing exceptional strength-to-weight ratios, thermal management, and energy absorption capabilities. These unique structures, inspired by the natural efficiency of a beehive, are crafted from metals like aluminum, stainless steel, and titanium, and have found extensive applications in aerospace, automotive, architecture, and environmental engineering.

Experience in integrating metal honeycomb structures into products reveals remarkable enhancements in performance and durability. When used as core materials in sandwich panels, they offer unparalleled rigidity and strength while drastically reducing weight. This results in enhanced fuel efficiency and overall performance in vehicles and aircraft, which is a critical concern for engineers and designers targeting sustainable solutions.

From an expertise standpoint, producing metal honeycombs requires precision engineering and advanced manufacturing techniques. The creation process involves expanding a metal sheet, bonding it in specific patterns, and then stretching it into a three-dimensional honeycomb structure. Each cell's size and the material choice are crucial, depending on the intended application, whether it's for lightweight structural cores or energy absorption panels. Advanced software and manufacturing technology allow for customization, optimizing the honeycomb's performance for specific needs.

Authoritativeness in the field of metal honeycombs has been established through rigorous testing and validation. For example, in the aerospace industry, metal honeycomb panels are subjected to extreme conditions to assess their performance under stress, temperature fluctuations, and mechanical forces. These tests ensure that the structures meet industry standards and certifications, providing confidence in their application across critical infrastructures.

Trustworthiness in the use of metal honeycombs stems from their proven track record in safety applications. In automotive design, metal honeycombs are employed in crash absorption systems. Their ability to deform predictably absorbs impact energy, safeguarding passengers and reducing injury risks. Moreover, their application in architectural structures has shown resilience in seismic zones, offering an additional layer of security.

metal honeycomb

A notable case is the incorporation of aluminum honeycomb cores in high-speed trains. These metal honeycombs have drastically reduced vehicle weight, leading to diminished energy consumption without compromising safety and comfort. The success of these designs in numerous high-profile projects underscores the reliability and effectiveness of metal honeycomb technology.

Moreover, metal honeycombs contribute significantly to thermal management in electronic devices. By facilitating effective heat dissipation, these materials prevent overheating, thereby enhancing the longevity and performance of sensitive components. This is particularly beneficial in rapidly advancing technologies where maintaining optimal operating temperatures is a persistent challenge.

In environmental engineering, metal honeycombs are utilized in catalyst supports for chemical reactions. Their high surface area and structural integrity make them ideal for maximizing efficiency in pollution control devices, such as catalytic converters. This application underscores the role of metal honeycombs in advancing environmental sustainability by reducing harmful emissions.

In conclusion, metal honeycombs represent a pinnacle of engineering efficiency, combining lightness with strength, and versatility with durability. Their various applications across industries not only demonstrate their practical benefits but also cement their status as a trusted material of choice for future innovations. As industries continue to push boundaries, the role of metal honeycombs in product design and development is poised to expand dramatically, aligning with the ongoing quest for sustainability and efficiency.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025