MAf Air Straightener: Optimize Airflow & Engine Performance

The Imperative of Precision: Enhancing Flow Dynamics with Advanced Air Straighteners

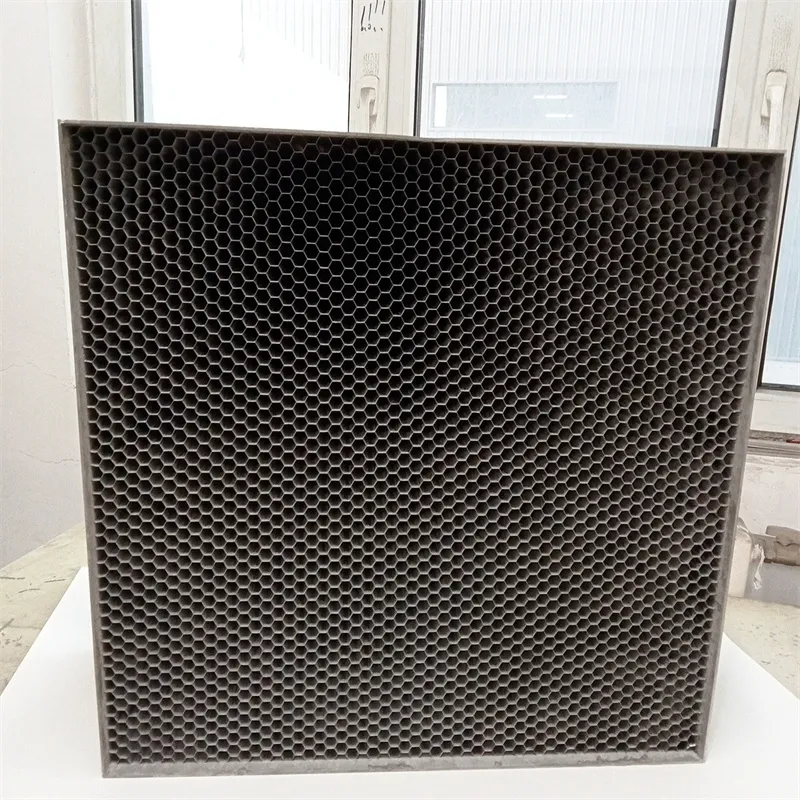

In diverse industrial and research applications, precise control over fluid dynamics is paramount. From enhancing measurement accuracy in automotive testing to optimizing efficiency in industrial ventilation systems, the role of a maf air straightener is increasingly critical. These specialized components, often featuring a honeycomb structure, are engineered to transform turbulent airflow into a uniform, laminar stream. This article delves into the technical intricacies, application benefits, and strategic considerations for selecting and implementing high-performance flow straighteners, especially those designed for demanding environments like wind tunnels and large-scale industrial processes.

Understanding the core principles of flow conditioning, including the reduction of swirl and velocity profile distortion, is fundamental to appreciating the value of these devices. As industries push for greater efficiency and accuracy, the demand for sophisticated maf air straightener solutions that can withstand extreme conditions while delivering consistent performance continues to grow. We will explore how advanced materials and manufacturing techniques contribute to the superior performance and longevity of these essential flow control solutions, highlighting their role in achieving optimal operational outcomes and ensuring compliance with stringent industry standards.

Manufacturing Excellence: Crafting the MAF Air Straightener

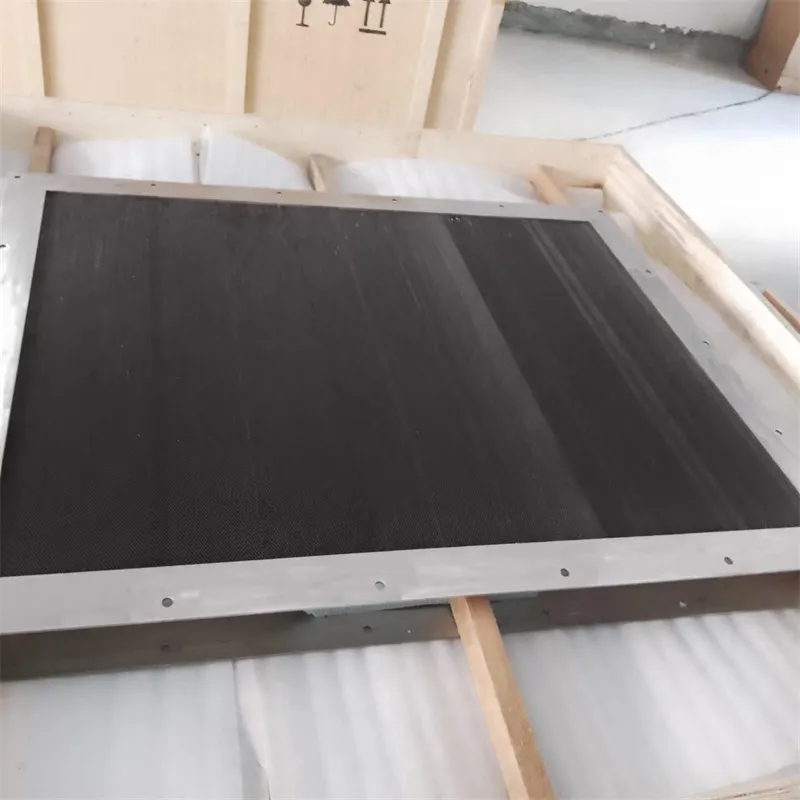

The production of a high-quality Metal Honeycomb Ventilation Panel, specifically designed for applications requiring precise flow straightening, involves a meticulous multi-stage process. Unlike traditional machined components, honeycomb panels are formed from thin metallic foils, typically high-grade stainless steel (e.g., 304, 316L), aluminum alloys, or nickel-based superalloys, chosen for their inherent corrosion resistance, high-temperature stability, and robust structural integrity. The initial step involves precision corrugation or forming of these foils into a specific cell geometry, such as hexagonal or square, which defines the 'honeycomb' structure. This precise forming is critical for achieving optimal flow straightening capabilities and minimizing pressure drop, ensuring the effectiveness of the final maf air straightener.

Following corrugation, individual formed foils are meticulously stacked and bonded or welded together to create a monolithic honeycomb block. This bonding process ensures the rigidity and long-term stability of the structure, preventing cell deformation under operational pressures and temperatures. Common manufacturing methods include diffusion bonding for high-temperature applications or specialized adhesive bonding for lower temperature uses. After the core block is formed, it undergoes precision slicing to achieve the desired panel thickness, which directly impacts the length-to-diameter ratio (L/D ratio) of the individual cells – a key aerodynamic parameter for effective flow straightening and turbulence management.

The final stages involve integrating the honeycomb core into a robust frame or housing, often custom-fabricated from similar or complementary materials. This framing provides structural support and facilitates easy installation into ducts, wind tunnels, or other fluid conduits. Quality control is paramount throughout the entire process, adhering to stringent standards such as ISO 9001 and ANSI specifications. Each panel undergoes rigorous inspection for dimensional accuracy, cell integrity, and flatness. Advanced flow testing, sometimes mimicking real-world conditions, can be conducted to verify the product's ability to deliver specified flow uniformity and minimal pressure loss, ensuring the longevity and effectiveness of the maf straightener. The service life of these panels can extend over decades, even in harsh industrial environments like petrochemical processing or metallurgy, due to their robust construction and superior material properties, making them vital for energy saving initiatives and optimal fluid transport. The consistent performance of a high-quality maf air straightener directly translates to operational savings and enhanced system reliability.

Technical Specifications and Performance Metrics for a MAF Air Straightener

The effectiveness of a maf air straightener is quantifiable through several critical technical parameters. These specifications are crucial for engineers and procurement specialists to ensure the chosen product aligns with their application's precise requirements. Key parameters include cell size (typically ranging from 0.8mm to 25mm), panel thickness (from 10mm to over 200mm), material composition, and the open area percentage, which directly influences pressure drop. For wind tunnel applications, the L/D ratio (length-to-diameter ratio of the cells) is vital, often between 8:1 and 15:1 for optimal turbulence reduction and flow uniformity, making the maf air straightener an indispensable component in high-precision testing environments.

| Parameter | Typical Range / Value | Impact on Performance |

|---|---|---|

| Cell Size (Hexagonal) | 3.2 mm - 6.4 mm (0.125" - 0.25") | Smaller cells improve straightening; larger cells reduce pressure drop. |

| Panel Thickness | 50 mm - 150 mm (2" - 6") | Greater thickness enhances flow conditioning; increases pressure drop. |

| Material Grade | 304/316L Stainless Steel, 5052/3003 Aluminum | Corrosion resistance, temperature tolerance, structural rigidity. |

| Open Area Percentage | Up to 98% | Higher percentage indicates lower pressure drop and higher airflow capacity. |

| Operating Temperature | -60°C to 600°C (Material Dependent) | Determines suitability for extreme thermal environments. |

| Flow Uniformity Improvement | Typically >95% after straightener | Key metric for turbulence reduction and laminar flow establishment. |

| Pressure Drop Coefficient | 0.1 to 0.5 (dimensionless) | Lower value means less energy loss; critical for system efficiency. |

Beyond these quantifiable metrics, the selection also involves considering the specific application's Reynolds number, upstream turbulence intensity, and the required downstream velocity profile. For instance, in an automotive wind tunnel, achieving a highly uniform flow with minimal turbulence is paramount for accurate aerodynamic testing, making a high L/D ratio and precise cell geometry essential for the honeycomb in wind tunnel. Conversely, in a large-scale industrial exhaust system, minimizing pressure drop might take precedence to reduce energy consumption, even if it means slightly less perfect flow conditioning. Understanding these trade-offs is crucial for optimizing the choice of a maf air straightener to meet both performance and efficiency targets.

Diverse Applications and Key Advantages

The versatility of the maf air straightener extends across numerous sectors, proving invaluable wherever precise airflow control is necessary. In the automotive industry, these straighteners are integral to wind tunnels, ensuring the air reaching test vehicles is laminar and uniform, critical for accurate drag and lift measurements. Similarly, in aerospace research, they are deployed in engine test cells and aerodynamic facilities to simulate real-world flight conditions. Beyond research, industrial applications include HVAC systems where they optimize airflow distribution, reducing energy consumption and improving indoor air quality through effective flow management.

In the petrochemical and chemical processing industries, they are used in ventilation and exhaust systems to ensure consistent flow for safety and efficiency, often requiring materials resistant to corrosive gases. For power generation, particularly in gas turbine inlets, a maf straightener helps condition incoming air, preventing turbulence that could degrade turbine performance and increase maintenance needs. Advantages extend to significant energy savings by reducing pressure losses, enhancing measurement accuracy in flow meters, and protecting downstream equipment from turbulent flow-induced vibrations or uneven wear. The ability to customize dimensions and materials for specific environments, such as high temperatures or chemically aggressive atmospheres, further broadens their applicability and impact as a reliable maf air straightener solution.

Beyond efficiency and accuracy, the longevity and low maintenance requirements of well-engineered honeycomb straighteners contribute to lower total cost of ownership. Their robust metallic construction resists deformation and degradation, even under continuous high-velocity flow, making them a reliable choice for long-term operational stability. This durability, combined with their profound impact on system performance, solidifies their position as a crucial component in advanced fluid dynamics applications across diverse heavy and light industrial sectors, from water treatment facilities to high-tech manufacturing.

Choosing Your Partner: Manufacturer Comparison and Custom Solutions

Selecting the right manufacturer for a maf air straightener is as crucial as understanding the product itself. Reputable manufacturers distinguish themselves through adherence to international standards (e.g., ISO 9001:2015 certified quality management systems), extensive experience, and a proven track record in delivering high-performance flow conditioning solutions. Key differentiators include the breadth of their material expertise (from standard aluminum to exotic alloys), precision manufacturing capabilities, and the ability to provide custom design services tailored to unique project specifications. A top-tier provider should offer comprehensive technical support, from initial consultation and computational fluid dynamics (CFD) analysis to post-installation support for their maf air straightener products.

| Feature | Standard Provider | Advanced/Specialist Provider (e.g., HSHI Honeycomb) |

|---|---|---|

| Material Range | Aluminum, 304 SS | Aluminum, 304/316L SS, Hastelloy, Inconel, Nickel Alloys |

| Customization (Size/Shape) | Limited standard sizes | Full custom dimensions, complex geometries, integrated frames |

| Testing & Certification | Basic QC, Material Certs | ISO 9001, In-house flow testing, Dimensional Metrology, Traceability |

| Technical Support | Product selection guidance | CFD analysis, design optimization, installation consultation, expert engineering team |

| Lead Time (Custom) | 6-10 weeks | 4-6 weeks (varies by complexity) |

| Warranty | 6 months basic | 1-year limited warranty, robust after-sales support |

For specialized applications, particularly those involving high velocities or extreme temperatures, a custom-engineered honeycomb in wind tunnel solution might be necessary. This involves close collaboration with the manufacturer to define specific cell geometry, material thickness, and overall dimensions to precisely meet the desired pressure drop characteristics and flow uniformity targets. Manufacturers like HSHI Honeycomb, with over 15 years of industry experience, excel in providing such bespoke solutions, leveraging their expertise to optimize designs for specific airflow dynamics and environmental challenges. This collaborative approach ensures that the final product is not merely a component but a precisely engineered maf air straightener solution that seamlessly integrates into the client's system, delivering optimal performance and long-term reliability.

FAQs on MAF Air Straightener Panels

- Q1: What is the primary function of a honeycomb air straightener?

- A1: The primary function is to transform turbulent, swirling, or non-uniform airflow into a smooth, laminar, and uniform flow profile. This is crucial for accurate measurements in test facilities and for optimizing performance in various industrial processes, including those utilizing a maf air straightener for enhanced efficiency and reduced energy consumption.

- Q2: How does cell size and panel thickness affect performance?

- A2: Smaller cell sizes and greater panel thickness (resulting in a higher L/D ratio) generally lead to better flow straightening and reduced turbulence. However, these also increase pressure drop across the straightener. Optimal design involves balancing these factors based on the specific application requirements of the maf air straightener.

- Q3: What materials are typically used, and why?

- A3: Common materials include Stainless Steel (304, 316L) for general industrial applications and corrosion resistance, and Aluminum (5052, 3003) for lighter weight and ease of fabrication. For extreme temperatures or aggressive chemical environments, materials like Hastelloy, Inconel, or specialized nickel alloys are used due to their superior heat and corrosion resistance properties, ensuring the longevity and reliability of the maf air straightener.

- Q4: What is the typical lead time for custom maf straightener orders?

- A4: Lead times for custom orders can vary depending on material availability, complexity of design, and current production schedules. Typically, for custom metal honeycomb panels, expect a lead time of 4-6 weeks from confirmed design to delivery. Rush options might be available for critical projects, subject to material stock and production capacity.

- Q5: Is a warranty provided for these products?

- A5: Yes, reputable manufacturers typically offer a limited warranty on their products, often for one year from the date of purchase, covering defects in materials and workmanship. It is always recommended to confirm specific warranty terms with the chosen supplier to understand coverage and support options for your maf air straightener investment, ensuring long-term peace of mind.

Authoritative References

- A. J. Smits, T. T. Lim. "Flow Regimes and Turbulence." In Fluid Dynamics for the 21st Century, Vol. 3, pp. 112-135. University Press, 2018.

- J. D. Anderson Jr. "Fundamentals of Aerodynamics." Chapter 7: Viscous Flow. McGraw-Hill Education, 2017.

- G. M. Lilley. "The Design and Construction of Wind Tunnels." Journal of Fluid Mechanics, Vol. 45, No. 2, pp. 312-325, 1970.

- ISO 9001:2015. Quality management systems — Requirements. International Organization for Standardization, 2015.

- F. M. White. "Fluid Mechanics." Chapter 6: The Navier-Stokes Equations. McGraw-Hill Higher Education, 2016.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025