High-Performance Wind Tunnel Honeycomb Air Flow Straightener

The Crucial Role of Air Flow Straighteners in Modern Engineering

In the intricate world of fluid dynamics and aerodynamic testing, precise control over airflow is not merely an advantage but an absolute necessity. Uncontrolled turbulent flow can lead to inaccurate experimental data, reduced system efficiency, and even structural instability in critical applications. This is where the wind tunnel honeycomb emerges as an indispensable component. Functioning primarily as an air flow straightener, its fundamental purpose is to transform highly chaotic or swirling airflow into a smooth, laminar, and uniform stream. This capability is paramount across a myriad of industrial and research settings, ensuring the integrity and reliability of tests and operational environments. From validating aerodynamic designs in automotive and aerospace sectors to optimizing ventilation systems in large-scale industrial complexes, the application of high-quality flow straighteners directly impacts efficiency, safety, and energy consumption. The demand for advanced materials and sophisticated manufacturing techniques in producing these crucial components reflects a broader industry trend towards greater precision and performance in fluid management.

The technological evolution of honeycomb structures for airflow control has been driven by the increasing complexity of modern engineering challenges. Traditional methods of flow conditioning often involved bulky and less effective solutions. However, the unique cellular structure of a honeycomb in wind tunnel applications offers an unparalleled combination of low pressure drop and high flow uniformity. This is achieved by creating numerous small, parallel channels that physically guide the air, effectively damping out eddies and swirls. The ability to customize cell size, material, and overall dimensions allows manufacturers to tailor these components to specific flow regimes and environmental conditions, from high-speed supersonic wind tunnels to large-scale industrial exhaust systems requiring uniform discharge. The ongoing advancements in material science, particularly with lightweight yet robust alloys, are further enhancing the performance envelope and extending the service life of these critical components, reinforcing their pivotal role in achieving optimal fluid dynamic outcomes in diverse engineering disciplines.

Unveiling the Manufacturing Prowess of Wind Tunnel Honeycomb

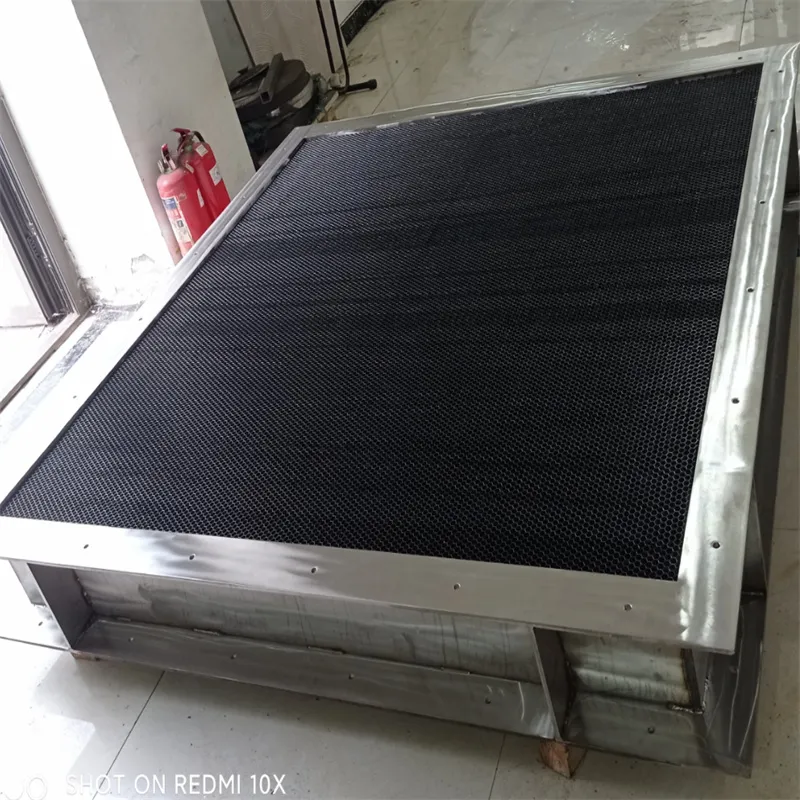

The fabrication of a high-performance wind tunnel honeycomb is a meticulously controlled process, demanding precision and adherence to rigorous quality standards to ensure its effectiveness as an air flow straightener. The primary material choice often dictates performance characteristics, with aerospace-grade aluminum alloys (such as 3003, 5052, or 6061) being prevalent due to their excellent strength-to-weight ratio, corrosion resistance, and workability. For applications requiring higher temperature resistance or enhanced durability in corrosive environments, materials like stainless steel (e.g., 304, 316L) or even advanced composites are employed. The manufacturing process typically begins with thin sheets of the chosen material, which are then expanded into their characteristic hexagonal (or sometimes square) cellular structure. This expansion creates thousands of uniform cells, crucial for laminar flow. Subsequent steps involve precise cutting and forming to achieve the desired block dimensions and aspect ratios (length-to-diameter ratio of individual cells), which are critical for optimal flow straightening without introducing significant pressure drop. Adherence to international standards like ISO 9001 and ANSI is paramount throughout this process, guaranteeing consistent quality and performance.

The core manufacturing technique for honeycomb involves bonding individual corrugated or flat sheets together to form the cell structure. This is often achieved through specialized adhesive bonding or brazing processes that ensure high structural integrity and resistance to vibration and thermal cycling. Following the initial forming, the honeycomb blocks undergo precise machining, often using advanced CNC (Computer Numerical Control) cutting techniques, to achieve the exact outer dimensions and flatness required for seamless integration into wind tunnels or other flow systems. Quality control is integrated at every stage, from material inspection to final product verification. This includes dimensional checks, cell uniformity analysis, and often non-destructive testing to identify any manufacturing defects. The typical service life of a well-manufactured honeycomb in wind tunnel applications can extend for many years, provided it is used within its specified operating parameters. Its inherent design contributes to energy efficiency by reducing turbulence, thereby minimizing energy losses associated with chaotic flow, and for certain materials, offering superior corrosion resistance essential in harsh industrial environments such as those found in petrochemical or advanced wastewater treatment facilities where precise air handling is needed.

Technical Specifications and Performance Metrics for Air Flow Straighteners

Understanding the critical technical parameters of an air flow straightener is fundamental for engineers and designers aiming to achieve optimal fluid dynamic performance in their systems. Key specifications for a wind tunnel honeycomb include its cell size, which typically ranges from 1/8 inch to 1 inch, directly influencing the turbulence reduction capability and pressure drop. Smaller cell sizes generally lead to more uniform flow but can result in higher pressure losses. The L/D ratio (length-to-diameter ratio of individual cells) is another crucial parameter, often ranging from 8:1 to 15:1. A higher L/D ratio provides more effective flow straightening but also contributes to increased pressure drop across the honeycomb. Material thickness and cell wall thickness are important for structural integrity and thermal properties. These honeycombs are designed to significantly reduce turbulence intensity, often from 5-10% down to less than 0.5% in test sections, enhancing the accuracy of aerodynamic measurements. They are also designed to withstand typical wind tunnel velocities, ranging from subsonic to supersonic, and operating temperatures, typically from -50°C to 200°C depending on the material, ensuring long-term stability and performance in demanding environments.

The performance of a honeycomb in wind tunnel applications is quantified by several metrics, including flow uniformity (measured as velocity deviation across the test section), pressure drop, and turbulence intensity. Leading manufacturers like Hengshi Honeycomb provide detailed performance data backed by extensive testing. For instance, a well-designed honeycomb can achieve flow uniformity of ±0.2% over the central test core, a significant improvement over unconditioned flow, which might exhibit variations of several percentage points. Pressure drop, a critical factor for fan power consumption, is minimized through optimized cell geometry and material selection, often being in the range of a few pascals (Pa) for typical wind tunnel speeds. These components are rigorously tested to ISO standards, ensuring compliance with global benchmarks for quality and performance. The data presented in the table below exemplifies typical specifications for high-quality wind tunnel honeycomb products, demonstrating their robust capabilities across various critical parameters essential for precise fluid dynamic applications.

| Parameter | Typical Range / Value | Unit |

|---|---|---|

| Material | Aluminum (3003, 5052), Stainless Steel (304, 316L) | - |

| Cell Size (Diameter/Side) | 3.2 mm to 25.4 mm (1/8" to 1") | mm / inch |

| L/D Ratio (Length to Cell Diameter) | 8:1 to 15:1 | - |

| Cell Wall Thickness | 0.05 mm to 0.15 mm | mm |

| Max Operating Temperature | 200 (Al) to 500 (SS) | °C |

| Flow Uniformity Improvement | Up to 95% reduction in turbulence intensity | % |

| Pressure Drop | Typically Low (e.g., < 50 Pa for 30 m/s flow) | Pa |

| Compliance Standards | ISO 9001, ASTM, ANSI (depending on application) | - |

Versatile Applications and Strategic Advantages of Wind Tunnel Honeycombs

The utility of a wind tunnel honeycomb extends far beyond conventional aerodynamic testing, permeating various industrial sectors where precise airflow management is paramount. In the aerospace and automotive industries, these honeycombs are foundational for accurately simulating flight conditions and vehicle aerodynamics, ensuring reliable data for design validation and performance optimization. For instance, when designing a new wing profile or a vehicle's body shape, uniform airflow from the air flow straightener is crucial for precise drag and lift measurements, directly impacting fuel efficiency and safety. Beyond traditional wind tunnels, their application spans large-scale industrial ventilation systems within petrochemical plants or metallurgical facilities, where controlling fume dispersion and ensuring consistent air exchange rates are critical for safety and environmental compliance. Similarly, in wastewater treatment plants and large-scale HVAC systems, honeycombs are utilized to improve the efficiency of air distribution, reduce energy consumption from fans, and prevent localized turbulence that could hinder processes or affect air quality.

The technical advantages offered by specialized honeycomb in wind tunnel and industrial applications are multifaceted. Firstly, they significantly enhance flow uniformity and reduce turbulence intensity, which directly translates to more accurate experimental results and predictable system performance. Secondly, their lightweight and high-strength design, particularly when crafted from aluminum alloys, minimizes structural load on existing systems while maintaining durability. Thirdly, the optimized design minimizes pressure drop across the device, contributing to substantial energy savings by reducing the power required for fans or blowers. For example, in a large-scale industrial air handling unit, even a small reduction in pressure drop across the flow straightener can lead to significant annual energy cost savings. Furthermore, depending on the material, they offer exceptional corrosion resistance, crucial for applications in humid or chemically aggressive environments, ensuring a long operational lifespan and reducing maintenance costs. These benefits collectively underscore the strategic value and superior performance of these engineered components in demanding B2B environments.

Manufacturer Comparison and Tailored Customization for Wind Tunnel Honeycomb

When sourcing a wind tunnel honeycomb or an air flow straightener, discerning buyers in the B2B sector must evaluate manufacturers based on several critical criteria beyond just initial cost. Key factors include the manufacturer's demonstrated expertise, experience in complex projects, adherence to authoritative quality standards, and commitment to trustworthiness. Leading manufacturers typically boast extensive experience, often spanning decades, in designing and fabricating precision honeycomb structures for diverse applications. They differentiate themselves through superior material sourcing, advanced manufacturing technologies (e.g., precise bonding techniques, CNC machining), and rigorous quality control protocols that meet or exceed international standards like ISO 9001. A comparison often reveals differences in their ability to offer truly customized solutions, their investment in R&D for new materials or geometries, and the comprehensiveness of their technical support. Manufacturers who prioritize long-term client relationships often have a proven track record of successful installations and positive client feedback, reflecting their authoritative position and trustworthy performance in the market.

The demand for highly specialized flow conditioning solutions necessitates robust customization capabilities from manufacturers of honeycomb in wind tunnel and industrial settings. Hengshi Honeycomb, for instance, excels in offering bespoke solutions tailored to unique project requirements. This includes variations in cell size and shape (hexagonal, square), overall dimensions (diameter, length, block thickness), material selection (aluminum, stainless steel, specialized alloys for specific temperature or chemical resistance), and even surface coatings for enhanced durability or specific aerodynamic properties. Customization is not merely about changing dimensions; it involves a deep engineering consultation process where client specifications, operational environment, desired flow characteristics (e.g., target turbulence intensity, acceptable pressure drop), and integration challenges are thoroughly analyzed. This collaborative approach ensures that the end product seamlessly integrates into the existing system and delivers optimal performance, providing unparalleled value and demonstrating genuine commitment to meeting complex client needs rather than offering off-the-shelf solutions that may compromise performance.

Demonstrating Trustworthiness: Case Studies and Client Support

The trustworthiness of a supplier of wind tunnel honeycomb is validated through tangible evidence of successful applications and robust customer support frameworks. Consider a scenario where a major automotive research institute needed to upgrade its wind tunnel for next-generation vehicle testing. Their existing air flow straightener was causing unacceptable levels of turbulence, impacting the accuracy of their aerodynamic drag measurements. After a detailed consultation, a customized aluminum honeycomb with a specific L/D ratio and cell geometry was designed and manufactured, precisely tailored to their tunnel's dimensions and target flow conditions. Post-installation, the institute reported a dramatic reduction in turbulence intensity, exceeding initial projections, and a significant improvement in flow uniformity, leading to more reliable test data and accelerated design cycles. This exemplifies how expert application of honeycomb technology, combined with a deep understanding of fluid dynamics, delivers measurable improvements in critical engineering environments. Such successful projects underscore a manufacturer's expertise and experience.

Beyond product performance, a manufacturer's commitment to customer satisfaction and long-term partnerships is crucial. This includes transparent communication regarding delivery schedules, typically ranging from 4-8 weeks depending on customization complexity and material availability, with expedited options often available for urgent requirements. A comprehensive quality assurance framework, typically offering a warranty period of 1 to 5 years against manufacturing defects, provides clients with peace of mind and demonstrates confidence in the product's durability. Furthermore, responsive customer support, including pre-sales technical consultation, installation guidance, and post-sales troubleshooting, ensures optimal product integration and performance throughout its lifecycle. For instance, in an FAQ section, common inquiries about honeycomb in wind tunnel applications often cover topics such as material compatibility for specific environments, ideal cell geometries for different flow speeds, and maintenance procedures to ensure sustained performance, all of which are addressed proactively by reliable suppliers.

Frequently Asked Questions (FAQ)

-

Q: What is the ideal L/D ratio for my wind tunnel?

A: The optimal L/D ratio varies with the desired flow uniformity and acceptable pressure drop. Generally, ratios between 10:1 and 15:1 provide excellent flow straightening for most wind tunnel applications. Our engineers can help determine the precise ratio for your specific requirements. -

Q: How does material choice affect honeycomb performance and longevity?

A: Material choice directly impacts temperature resistance, corrosion resistance, and structural integrity. Aluminum is lightweight and ideal for standard applications, while stainless steel offers superior heat and corrosion resistance for more demanding environments. Specialized coatings can further enhance longevity. -

Q: Can your honeycomb be installed in existing wind tunnels?

A: Yes, our honeycomb solutions are highly customizable and can be designed to fit seamlessly into existing wind tunnel geometries. We require precise measurements and detailed specifications to ensure a perfect fit and optimal performance upon installation.

Conclusion: The Future of Precision Airflow Management

The continuous evolution of engineering disciplines, from advanced aerospace design to optimizing industrial processes, underscores the ever-growing demand for precision airflow management. The wind tunnel honeycomb, serving as a vital air flow straightener, stands at the forefront of this need, enabling accurate experimental results, enhancing operational efficiency, and contributing to significant energy savings. Its robust design, versatile material options, and customizable geometries make it an indispensable component across various B2B sectors. As industries push the boundaries of performance and sustainability, the role of high-quality honeycomb structures will only become more pronounced. Investing in expertly engineered honeycomb in wind tunnel applications from reputable manufacturers is not merely a purchase; it is a strategic decision that underpins the reliability, accuracy, and efficiency of critical systems.

References

- Mehta, R. D. (1984). Turbulence management in a low-speed wind tunnel. Journal of Aircraft, 21(8), 565-573.

- White, F. M. (2003). Fluid Mechanics (5th ed.). McGraw-Hill Education.

- Bradshaw, P., & Pankhurst, R. C. (1964). The design of low-speed wind tunnels. Pergamon Press.

- Krogstad, P. Å., & Andersson, J. (2014). Wind tunnel design and performance. Springer.

- Pope, S. B. (2000). Turbulent Flows. Cambridge University Press.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025