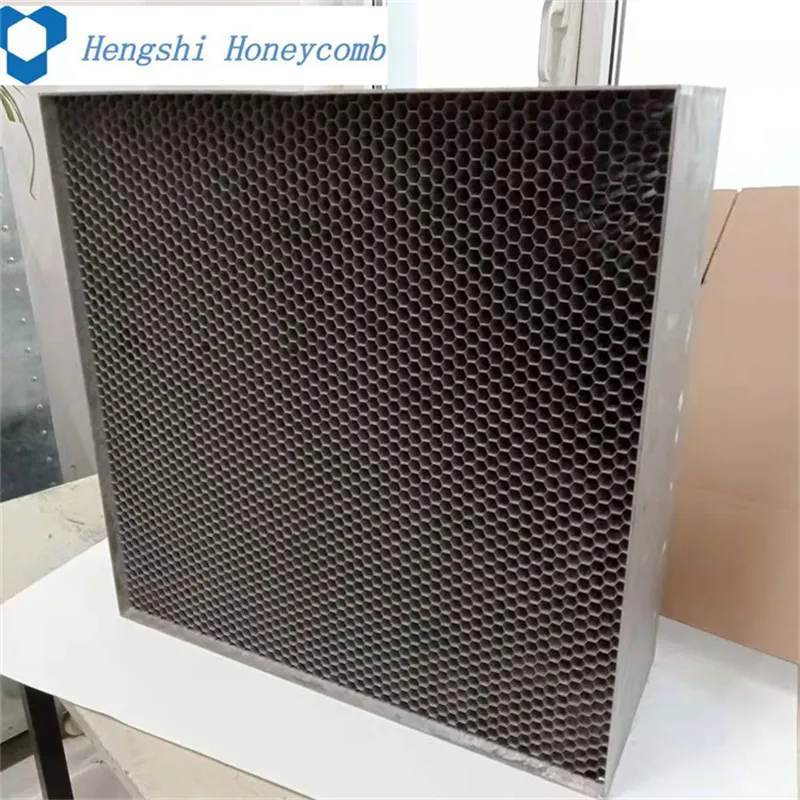

Precision Honeycomb Models: Air Flow Straighteners for Wind Tunnels

The Indispensable Role of Precision Honeycomb Models in Aerodynamic Testing

In the sophisticated realm of aerodynamic research and industrial design, achieving precise and consistent airflow is paramount. This is where the honeycomb model emerges as a critical component, primarily functioning as an air flow straightener. Its unique cellular structure is engineered to convert turbulent, erratic airflow into a highly uniform, laminar stream, which is essential for accurate data acquisition in wind tunnels. Beyond its core function in flow conditioning, these advanced honeycomb structures play a vital role across various industries demanding rigorous control over fluid dynamics, from aerospace engineering to automotive development and industrial ventilation systems. The adoption of high-precision honeycomb designs significantly enhances the fidelity of experimental results, reduces design iterations, and ultimately contributes to the development of more efficient and reliable products. Understanding the technical intricacies, manufacturing excellence, and diverse applications of these components is crucial for any organization aiming to push the boundaries of aerodynamic performance.

The demand for ever more precise testing environments continues to drive innovation in honeycomb design and material science. Modern wind tunnel facilities rely heavily on the impeccable performance of their flow conditioning elements. The proper selection and integration of a honeycomb model directly impact the quality of data, influencing everything from drag coefficients to lift characteristics and pressure distributions. This foundational element ensures that expensive and time-consuming tests yield credible, repeatable outcomes, thereby accelerating product development cycles and minimizing risk. As industries strive for optimized designs and reduced energy consumption, the role of a superior flow straightener becomes increasingly critical, establishing the honeycomb model as an investment in data integrity and engineering excellence.

Technical Principles and Advantages in Wind Tunnels

The fundamental principle behind a honeycomb in wind tunnel applications is its ability to absorb cross-stream velocity components while allowing the axial flow to pass unimpeded. This is achieved through a meticulously designed array of cells, typically hexagonal or square, which force the airflow to align with the central axis of the tunnel. This process effectively reduces turbulence intensity, evens out velocity profiles, and minimizes flow angularity, creating a highly uniform flow field crucial for accurate aerodynamic measurements. Without an effective air flow straightener, boundary layer separation, pressure fluctuations, and unreliable test data become prevalent issues, compromising the validity of experimental results.

Key technical advantages of utilizing a high-quality honeycomb model include:

- Turbulence Reduction: Achieves turbulence levels typically below 0.1% of the free-stream velocity, which is critical for sensitive tests.

- Flow Uniformity: Ensures a consistent velocity distribution across the test section, reducing spatial variations to within ±0.5%.

- Reduced Flow Angularity: Minimizes flow deviation angles, often to less than 0.1 degrees, ensuring accurate angle-of-attack measurements.

- Enhanced Data Accuracy: By creating ideal testing conditions, the honeycomb model directly contributes to higher precision in aerodynamic force, pressure, and flow visualization studies.

- Optimized Test Efficiency: Fewer re-runs are needed due to inconsistent flow, saving significant operational time and costs in research and development.

Manufacturing Excellence and Quality Assurance

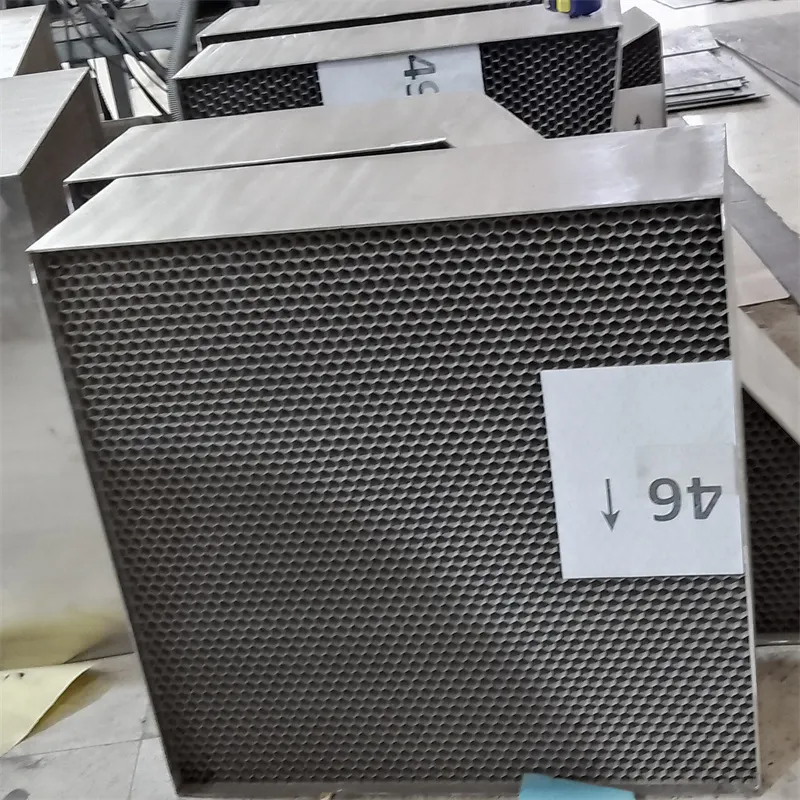

The manufacturing of a high-performance honeycomb model is a meticulous process demanding precision and expertise. Typically, these components are fabricated from materials such as aluminum, stainless steel, or composites like aramid fiber and carbon fiber, chosen for their specific strength-to-weight ratio, corrosion resistance, and thermal stability. Aluminum is favored for its lightweight properties and ease of machining, while stainless steel offers superior corrosion resistance and strength for more demanding environments. The manufacturing process often begins with the precise bonding or brazing of thin foil sheets to form the desired cellular structure. This can involve adhesive bonding, resistance welding, or vacuum brazing, depending on the material and application.

Following the core formation, precision cutting and shaping are performed to achieve the exact dimensions required for the wind tunnel. This often involves specialized CNC cutting techniques to ensure clean edges and precise cell geometry. Quality control is paramount throughout this process, adhering to stringent inspection standards such as ISO 9001 and internal ANSI-aligned protocols. Each honeycomb model undergoes rigorous testing, including visual inspections for cell integrity, dimensional checks for length and diameter uniformity, and, crucially, air flow resistance and pressure drop measurements to verify its performance as an air flow straightener. Our products are designed for a service life exceeding 15-20 years under typical operating conditions, a testament to their robust construction and material selection. In specialized applications like aerospace testing, where absolute minimal turbulence is required, our honeycombs are designed to maintain their structural and performance integrity over extended periods, ensuring consistent and reliable results.

Key Technical Parameters and Specifications

Selecting the correct honeycomb model requires a thorough understanding of its technical specifications. These parameters dictate the effectiveness of the honeycomb in wind tunnel applications and its suitability for specific testing requirements. Below is a table outlining typical parameters for high-performance air flow straightener units:

| Parameter | Typical Range/Value | Impact on Performance |

|---|---|---|

| Cell Size (Diameter/Side Length) | 1.5 mm to 25 mm | Smaller cells increase flow straightening but also pressure drop. |

| Length-to-Diameter Ratio (L/D) | 8:1 to 15:1 | Higher L/D improves flow straightening and reduces turbulence. |

| Material Thickness (Foil Gauge) | 0.05 mm to 0.5 mm | Thinner walls reduce blockage but can compromise rigidity. |

| Open Area | 95% to 99% | Higher open area means lower pressure drop, but less structure. |

| Pressure Drop Coefficient (K) | 0.2 to 0.8 (typically) | Lower K indicates less energy loss; crucial for power efficiency. |

| Operating Temperature Range | -50°C to +200°C (material dependent) | Ensures structural integrity and performance across conditions. |

These parameters are meticulously balanced to deliver the ultimate aerodynamic efficiency for your wind tunnel testing. Our product line, "Revolutionize Your wind tunnel testing with precision Honeycomb cells ultimate aerodynamic Efficiency," is engineered to meet or exceed these critical specifications, providing unparalleled performance for the most demanding applications. We collaborate closely with clients to tailor solutions that fit their unique aerodynamic testing needs, ensuring optimal flow conditioning and data fidelity.

Application Scenarios and Industry Impact

The versatility and effectiveness of the honeycomb model extend across a wide array of industries, each benefiting from its ability to create highly controlled airflow environments. In the aerospace industry, these honeycombs are indispensable in wind tunnels used for aircraft and spacecraft design, enabling precise measurement of lift, drag, and control surface effectiveness. Their role ensures the accuracy of computational fluid dynamics (CFD) validations, leading to safer, more fuel-efficient aircraft. For automotive engineering, honeycomb in wind tunnel setups is crucial for optimizing vehicle aerodynamics, reducing drag, improving stability, and even enhancing cooling system performance, directly impacting fuel economy and handling characteristics.

Beyond traditional wind tunnels, the honeycomb model also finds critical application in:

- HVAC Systems: Used as air flow straightener units in large ventilation systems to ensure even air distribution, improving efficiency and comfort in commercial and industrial buildings.

- Acoustic Testing: In anechoic chambers, honeycombs can help create uniform airflow for noise measurement without introducing additional turbulence-generated sound.

- Industrial Fans and Turbomachinery: Integrated into fan inlets or outlets to optimize flow, reduce turbulence, and improve overall system efficiency and performance.

- Research & Development Facilities: Essential for academic and private research labs conducting fundamental fluid mechanics studies, ensuring the integrity of experimental setups.

Manufacturer Comparison and Customization Solutions

When selecting a provider for a honeycomb model, discerning buyers prioritize several key factors beyond mere cost. Leading manufacturers distinguish themselves through their material expertise, precision engineering capabilities, and commitment to quality. While many suppliers offer standard sizes, the true value lies in a manufacturer's ability to provide bespoke customization solutions. For instance, some providers might specialize in aluminum honeycombs for their lightweight properties, ideal for high-speed wind tunnels, while others excel in stainless steel or composite materials for corrosive or high-temperature environments. Our company stands out by offering a comprehensive range of materials and the flexibility to tailor every aspect of the air flow straightener.

Our specialization in precision honeycomb cells allows us to offer:

- Material Flexibility: From aerospace-grade aluminum to high-strength composites, we match materials to your specific environmental and performance needs.

- Custom Geometries: Beyond standard hexagonal cells, we can produce square, rectangular, or even custom-shaped cells to fit unique ducting or test section geometries.

- Tailored Dimensions: Exact length, width, and depth specifications, often required for retrofitting existing wind tunnels or integrating into compact systems.

- Optimized L/D Ratios: Fine-tuning the length-to-diameter ratio of individual cells to achieve specific turbulence reduction and pressure drop targets.

- Integrated Solutions: Ability to supply honeycomb models integrated into frames, with flanges, or designed for seamless modular assembly, simplifying installation.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of a honeycomb model in a wind tunnel?

A: The primary function of a honeycomb model is to act as an air flow straightener. It converts turbulent and non-uniform airflow into a smooth, laminar flow with minimal swirl and consistent velocity across the test section. This is crucial for obtaining accurate and repeatable aerodynamic data during experiments.

Q2: What materials are typically used for wind tunnel honeycombs?

A: Common materials include aluminum (for lightweight and general applications), stainless steel (for corrosion resistance and strength), and advanced composites like fiberglass, aramid fiber, or carbon fiber for specific properties such as high stiffness, low thermal expansion, or use in non-magnetic environments. The choice depends on the specific wind tunnel operating conditions and desired performance characteristics of the honeycomb in wind tunnel.

Q3: How does cell size and L/D ratio affect performance?

A: Generally, smaller cell sizes and higher Length-to-Diameter (L/D) ratios lead to better flow straightening and lower turbulence levels. A larger L/D ratio provides more opportunities for the flow to align with the cell axis. However, these also increase the pressure drop across the honeycomb model, requiring more fan power. An optimal balance is sought based on the specific wind tunnel's design and performance requirements.

Q4: What is the typical lead time for a custom honeycomb model?

A: The lead time for a custom honeycomb model varies depending on complexity, material availability, and current production schedules. For standard or semi-custom designs, lead times can range from 4-8 weeks. Highly specialized or large-scale projects may require 10-16 weeks. We work closely with our clients to provide accurate lead time estimates and adhere to delivery schedules, ensuring that your project timeline is respected. Our dedicated customer support team provides real-time updates and ensures seamless coordination from order placement to final delivery.

Q5: What kind of warranty or after-sales support do you offer?

A: We stand behind the quality and performance of our "Revolutionize Your wind tunnel testing with precision Honeycomb cells ultimate aerodynamic Efficiency" products. All our honeycomb model units come with a comprehensive 5-year warranty against manufacturing defects and material failures under normal operating conditions. Our after-sales support includes technical consultation for installation, maintenance guidelines, and troubleshooting assistance. We are committed to ensuring the long-term optimal performance of your air flow straightener, providing unparalleled support throughout its service life.

Conclusion: Elevating Aerodynamic Performance

The strategic integration of a high-quality honeycomb model is not merely an addition to a wind tunnel; it is a fundamental enhancement that directly impacts the integrity and reliability of aerodynamic data. As demonstrated, these precision-engineered components, acting as essential air flow straightener devices, are critical in transforming chaotic airflow into a highly uniform, laminar stream. This foundational capability underpins accurate research, efficient product development, and the precise validation of theoretical models across sectors from aerospace to automotive engineering.

Our commitment to manufacturing excellence, coupled with deep technical expertise, ensures that each honeycomb in wind tunnel solution we provide meets the most stringent performance criteria. By leveraging advanced materials, precise manufacturing processes, and rigorous quality control, we deliver components that offer superior turbulence reduction, flow uniformity, and long-term durability. Investing in our precision honeycomb cells means investing in unparalleled data accuracy, operational efficiency, and a competitive edge in your field. Partner with us to revolutionize your wind tunnel testing capabilities and achieve ultimate aerodynamic efficiency.

References

- Mehta, R. D. (1998). A guide to wind tunnel design and testing. National Research Council Canada, National Aeronautical Establishment.

- White, F. M. (2016). Fluid Mechanics. McGraw-Hill Education.

- Pope, A., & Harper, J. J. (1966). Low-Speed Wind Tunnel Testing. John Wiley & Sons.

- Barlow, J. B., Rae, W. H., & Pope, A. (1999). Low-Speed Wind Tunnel Testing. John Wiley & Sons, Inc.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025