- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

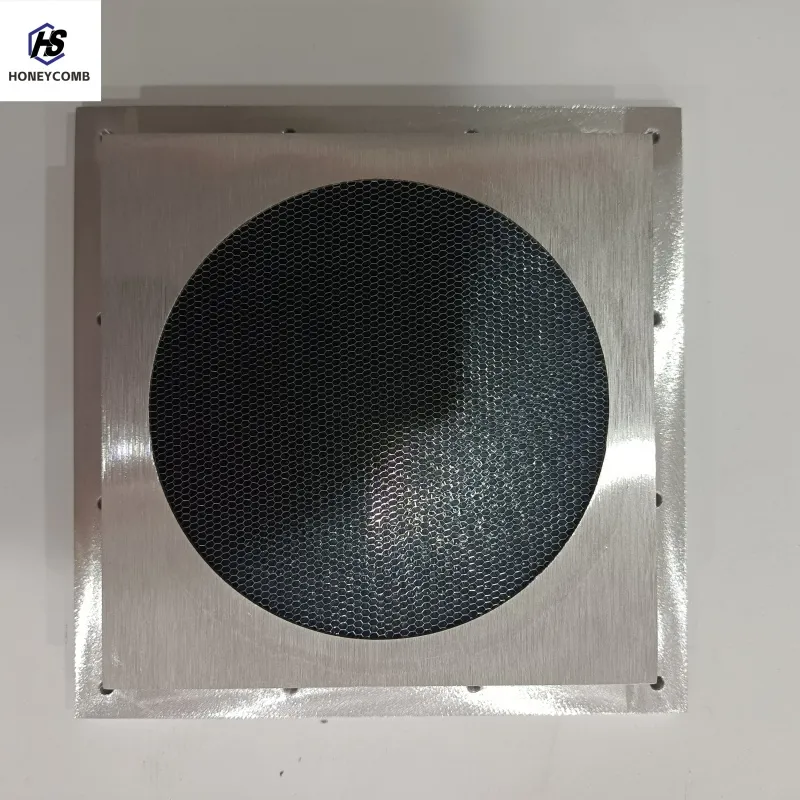

honeycomb plate

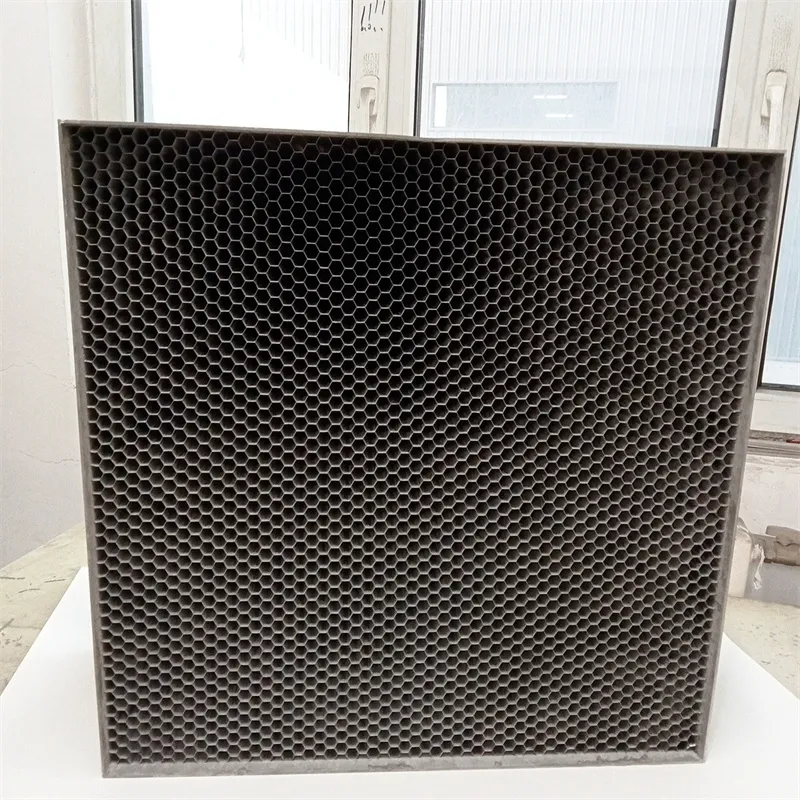

The emergence of honeycomb plates in industrial and architectural applications has sparked a revolution in material science, providing innovative solutions for weight reduction and structural integrity. Honeycomb plates, with their unique hexagonal structures, have become increasingly popular due to their unparalleled strength-to-weight ratio, versatility, and eco-friendliness.

Enhancing product performance and efficiency is one of the core promises of honeycomb plates. Made from a variety of materials including aluminum, paper, and plastic, these plates can be tailored to meet specific needs across different sectors. Their design mimics the natural geometry found in beehives, where the hexagonal pattern is optimized for functionality and aesthetic appeal. This configuration allows for a lightweight yet incredibly strong material, capable of withstanding significant loads while reducing material costs.

The application of honeycomb plates extends to various industries such as aerospace, construction, automotive, and transportation. In aerospace, the demand for fuel-efficient and lightweight materials is paramount. Honeycomb plates provide the necessary structural strength needed for aircraft components, all while significantly reducing weight, which translates to improved fuel efficiency and cost savings. Similarly, in the automotive industry, these plates are used to enhance vehicle performance while ensuring safety standards are met. They serve crucial roles in energy absorption during impacts, thanks to their inherent ability to dissipate energy effectively.

Architecturally, honeycomb plates offer transformative design capabilities. Architects and designers leverage their lightweight and flexible nature to explore complex geometric shapes without compromising durability. This allows for innovative building structures and facade systems that deliver both aesthetic value and functional benefits. The exceptional thermal insulation properties of honeycomb plates also contribute to energy savings in building design, making them a sustainable choice for modern construction practices.

Materials expertise is at the core of optimizing honeycomb plate performance. Understanding the distinct properties of each material type used in honeycomb construction is crucial. For instance, aluminum honeycomb panels are favored for their corrosion resistance and high tensile strength, making them ideal for outdoor applications. On the other hand, paper-based honeycomb is a cost-effective solution for temporary structures or interior applications where moisture resistance is not a primary requirement. The versatility of these plates makes them adaptable across climates and usage scenarios.

honeycomb plate

Trustworthiness is inherent in the safety assurances provided by honeycomb structures. Through rigorous testing, these plates have shown remarkable performance in fire resistance and acoustical dampening, making them suitable for safety-critical applications. Certification from recognized industry bodies further bolsters their reliability, ensuring that stakeholders can trust in their utilization.

What sets honeycomb plates apart is their environmental sustainability. Many variants are manufactured using recycled materials and can be fully recycled at the end of their lifecycle, aligning with global goals for reducing carbon footprints. This eco-friendly attribute addresses the growing demand for sustainable building practices and products that align with environmental conservation efforts.

The potential for innovation with honeycomb plates continues to expand. As research and development efforts push the boundaries, new composite materials are being developed, promising to enhance the already impressive capabilities of honeycomb structures. Future advancements may bring about further reductions in manufacturing costs and improvements in structural performance, opening up new applications and opportunities for these remarkable materials.

In conclusion, honeycomb plates represent a paradigm shift in material technology, offering a combination of light weight, strength, and sustainability that few other materials can match. Their adaptability across industries, combined with rigorous evidence of safety and performance, make them an authoritative choice in design and engineering projects. Experts in the field continue to explore their potential, ensuring honeycomb plates remain a cutting-edge solution for contemporary challenges in construction and manufacturing.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025