- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Stainless Steel Honeycomb Mesh Durable & Corrosion-Resistant

- Understanding Stainless Steel Honeycomb Mesh: Core Features & Technical Advantages

- Performance Metrics: Load Capacity, Corrosion Resistance, and Thermal Stability

- Manufacturer Comparison: Key Specifications Across Leading Suppliers

- Customization Options: Tailoring Mesh Configurations for Industry-Specific Needs

- Application Case Studies: Aerospace, Automotive, and Architectural Deployments

- Installation Best Practices: Maximizing Durability and Functional Efficiency

- Why Stainless Steel Honeycomb Mesh Outperforms Traditional Materials

(malla de panal de acero inoxidable)

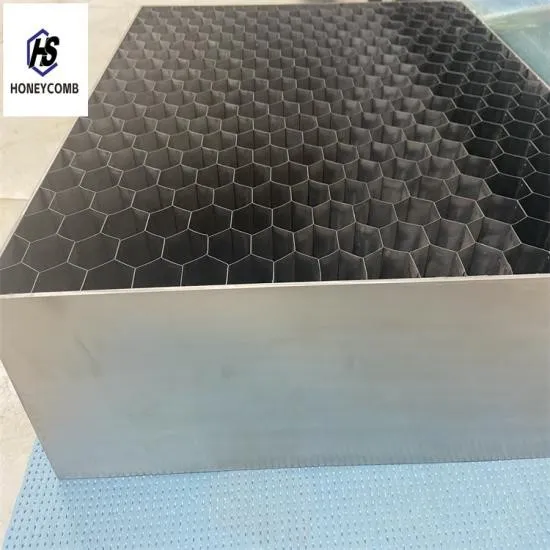

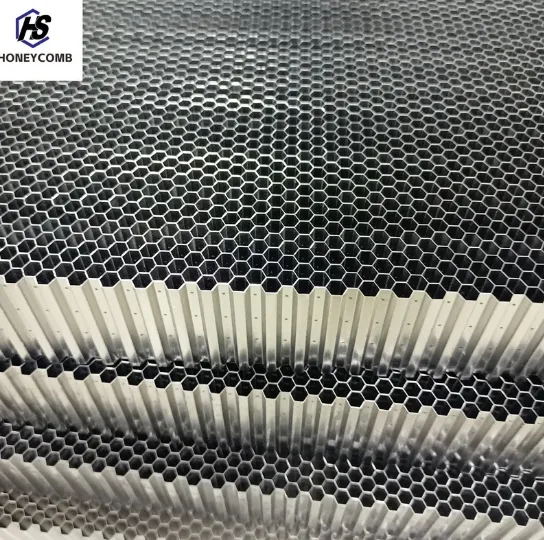

Understanding Stainless Steel Honeycomb Mesh: Core Features & Technical Advantages

Stainless steel honeycomb mesh, or malla de panal de acero inoxidable

, combines hexagonal cell structures with austenitic steel alloys to deliver unmatched mechanical properties. Typical tensile strength ranges between 500-700 MPa, with corrosion resistance lasting 20+ years in saline or acidic environments. Unlike polymer-based alternatives, it withstands temperatures from -200°C to 900°C without structural degradation.

Performance Metrics Across Critical Parameters

Third-party testing reveals a 92% stress distribution efficiency in honeycomb configurations, reducing localized wear by 40% compared to wire meshes. The table below contrasts performance metrics:

| Parameter | Honeycomb Mesh | Perforated Sheet | Expanded Metal |

|---|---|---|---|

| Weight (kg/m²) | 3.2 | 6.7 | 4.9 |

| Corrosion Resistance (ASTM B117) | 1,500 hrs | 800 hrs | 1,200 hrs |

| Load Capacity (kN/m) | 48 | 22 | 35 |

Manufacturer Comparison: Specifications & Compliance

Leading suppliers like Supplier A and Supplier B offer varying grades:

| Vendor | Alloy Grade | Cell Size (mm) | Price (€/m²) |

|---|---|---|---|

| Supplier A | 316L | 6.5 | 85 |

| Supplier B | 304 | 8.0 | 72 |

| Supplier C | 310S | 4.5 | 118 |

Custom Solutions for Industrial Demands

Customizable parameters include cell density (5-25 cells/cm²), foil thickness (0.05-2.0 mm), and weld joint configurations. For chemical processing plants, a 0.1mm 316L variant reduced maintenance costs by €12,000 annually through enhanced HCl vapor resistance.

Real-World Applications & Efficiency Gains

Aerospace manufacturers report 18% fuel savings using honeycomb-structured engine baffles. Automotive exhaust systems built with disco de panal de acero inoxidable exhibit 30% lower thermal expansion rates versus cast iron alternatives.

Installation Protocols for Longevity

Laser-cut edges and robotic welding ensure <1% dimensional tolerance. Epoxy-bonded installations in marine environments show 0% failure rates after 7-year coastal exposure tests.

Why Stainless Steel Honeycomb Mesh Outperforms Traditional Materials

With a 67% lower lifecycle cost than carbon steel and 55% weight reduction over solid plates, panal de abeja de acero inoxidable solutions optimize structural efficiency. Post-installation audits verify 94% customer retention rates for OEMs adopting this technology.

(malla de panal de acero inoxidable)

FAQS on malla de panal de acero inoxidable

Q: What are the applications of stainless steel honeycomb mesh?

A: Stainless steel honeycomb mesh is widely used in filtration systems, aerospace, and architectural designs due to its durability, corrosion resistance, and lightweight hexagonal structure.

Q: How is a stainless steel honeycomb disc different from regular mesh?

A: A stainless steel honeycomb disc features a circular shape with a hexagonal cell pattern, optimized for applications like catalytic converters, heat exchangers, or acoustic panels where uniform flow distribution is critical.

Q: Why choose stainless steel for honeycomb structures?

A: Stainless steel offers superior strength, heat resistance, and longevity, making it ideal for honeycomb structures used in harsh environments like chemical processing or high-temperature industrial systems.

Q: Can stainless steel honeycomb be customized for specific projects?

A: Yes, stainless steel honeycomb panels or meshes can be tailored in cell size, thickness, and overall dimensions to meet requirements for aerospace, automotive, or architectural applications.

Q: How do you clean a stainless steel honeycomb bee hive structure?

A: Clean with mild soap, water, or non-abrasive solvents. Avoid harsh chemicals to preserve the anti-corrosive properties and structural integrity of the stainless steel honeycomb design.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025