Honeycomb Air Flow Straightener-Hengshi|Aerodynamic Testing&Shielding

Discover the innovative Honeycomb Stainless Steel Air Flow Straightener, a cutting-edge solution designed to enhance airflow stability and measurement accuracy in aerodynamic testing. This product, developed by Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd., combines advanced engineering with high-quality materials to meet the demands of industries ranging from aerospace to automotive. In this article, we will explore the product's features, technical specifications, applications, and the company's commitment to excellence.

Product Introduction

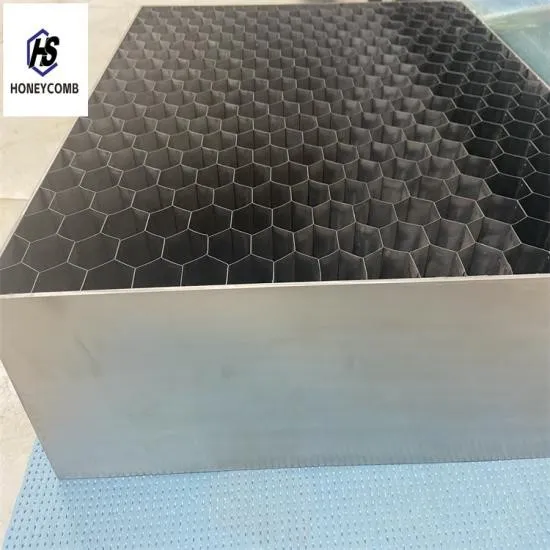

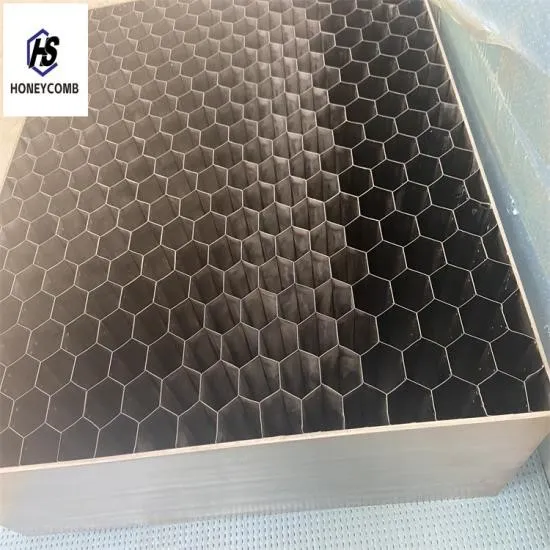

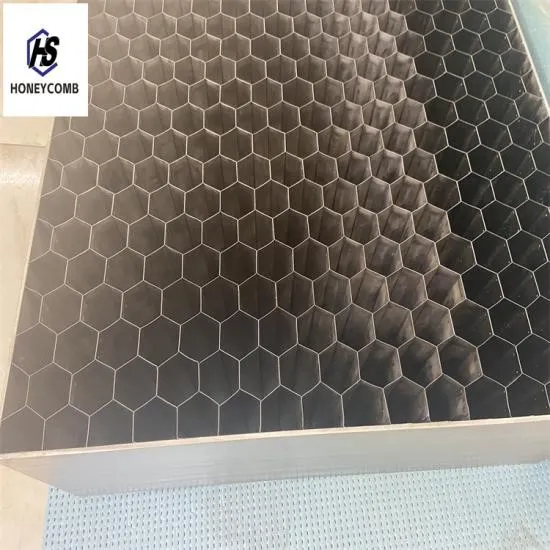

The Honeycomb Stainless Steel Air Flow Straightener is a critical component in wind tunnel systems, designed to transform turbulent airflow into laminar flow. This process is essential for achieving precise aerodynamic measurements in various industrial applications. The product's unique honeycomb structure, composed of thin cell walls, provides an array of straight passageways with a maximum open area of 95-99%, minimizing pressure drop and turbulence. This innovation ensures that airflow remains stable and consistent, which is vital for accurate testing and analysis.

Originally developed for use in the automotive and aerospace industries, the Honeycomb Air Flow Straightener has since expanded its applications to include testing for buildings, high-speed trains, and ships. Its versatility makes it an indispensable tool for engineers and researchers seeking to optimize the aerodynamic performance of their designs.

Product Application

Wind tunnels are essential research tools for studying aerodynamic effects, and the Honeycomb Stainless Steel Air Flow Straightener plays a pivotal role in their functionality. By stabilizing airflow, this product enables precise measurement of air resistance, heat resistance, and pressure resistance in various structures and vehicles. For instance, in the aerospace industry, it is used to test the aerodynamic effects of aircraft, missiles, and other high-speed vehicles. In the automotive sector, it helps engineers analyze the performance of cars under different wind conditions.

According to the National Institute of Standards and Technology (NIST), wind tunnels are crucial for advancing technological innovation, as they provide a controlled environment for testing and development. The Honeycomb Air Flow Straightener enhances the accuracy of these tests, ensuring that the data collected is reliable and actionable. This is particularly important in industries where even minor deviations can lead to significant performance issues.

Additionally, the Honeycomb Stainless Steel Air Flow Straightener is used in the design and testing of high-speed trains and ships, where aerodynamic efficiency is critical. By reducing turbulence and improving airflow, it contributes to the overall performance and safety of these transportation systems.

Technical Specifications

The Honeycomb Stainless Steel Air Flow Straightener is available in a variety of materials, including carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, aluminum, brass, and copper. This range of materials ensures that the product can be tailored to meet the specific requirements of different applications. The foil thickness options range from 0.05mm to 0.2mm, allowing for customization based on the desired level of airflow control.

The core size of the Honeycomb Air Flow Straightener is also highly customizable, with options ranging from 0.8mm to 30mm. This flexibility makes it suitable for a wide range of wind tunnel configurations and testing scenarios. The product's thickness can be adjusted to meet specific design requirements, while its shape can be customized to fit various installation spaces.

Surface treatments such as painting, white oxygen, electroless nickel plating, electrophoresis, and powder coating are available to enhance the product's durability and corrosion resistance. These treatments ensure that the Honeycomb Stainless Steel Air Flow Straightener can withstand harsh environments and maintain its performance over time.

The Honeycomb Air Flow Straightener is manufactured using spot welding and vacuum brazing technologies, ensuring a high level of structural integrity and performance. It is certified to ISO9001 and RoHS standards, reflecting the company's commitment to quality and environmental responsibility.

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper, etc. |

|---|---|

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, 6.0, 8, 10, 12, 20, 30mm (as required) |

| Thickness | Customized |

| Shape | As required |

| Surface Treatment | Painting, white oxygen, Electroless Nickel plating, electrophoresis, powder coating, Brush (as required) |

| Package | Wooden cases; or as required |

| Certificate | ISO9001, RoHS |

| Welding Technology | Spot welding, vacuum brazing |

| Function | EMI Shielding, Air Ventilation, Cooling, Corrosion Resistance |

| Application | EMI shielding vent, flow straightener, railways, Marine, aviation & aerospace, wind energy, defence, gas seals, communications, medical and other industries. |

Key Advantages of the Honeycomb Stainless Steel Air Flow Straightener

The Honeycomb Stainless Steel Air Flow Straightener offers several advantages that make it an ideal choice for aerodynamic testing. One of its primary benefits is its high shielding effectiveness, which provides excellent protection against electromagnetic interference (EMI). This feature is particularly valuable in industries such as telecommunications and medical equipment, where EMI can disrupt operations and compromise data integrity.

Another key advantage is its anti-corrosion properties, which ensure long-term durability in harsh environments. The use of high-quality materials like 304 and 316L stainless steel enhances the product's resistance to rust and corrosion, making it suitable for outdoor and industrial applications. Additionally, the Honeycomb Air Flow Straightener offers excellent sound insulation and ventilation effects, contributing to a quieter and more efficient testing environment.

According to NIST, the integration of advanced materials and engineering techniques is essential for achieving precise and reliable results in aerodynamic testing. The Honeycomb Stainless Steel Air Flow Straightener exemplifies this principle, combining high-performance materials with innovative design to deliver exceptional results.

Company Background: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

Founded with a commitment to excellence, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. has established itself as a leading manufacturer of high-quality shielding products, including ventilation panels, steel honeycomb cores, honeycomb air flow straighteners, and honeycomb seals. The company's expertise in precision engineering and advanced manufacturing processes has enabled it to become a trusted partner for industries requiring reliable and high-performance solutions.

Hengshi's dedication to innovation and quality is reflected in its comprehensive product range and adherence to international standards such as ISO9001 and RoHS. The company's state-of-the-art facilities and skilled workforce ensure that each product meets the highest standards of performance and durability. By continuously investing in research and development, Hengshi remains at the forefront of technological advancements in the field of aerodynamic testing and shielding solutions.

As a manufacturer with a global reach, Hengshi serves a diverse range of industries, including aerospace, automotive, marine, and defense. Its products are designed to meet the specific needs of each application, ensuring optimal performance and reliability. The company's commitment to customer satisfaction is evident in its responsive support and tailored solutions, making it a preferred choice for businesses seeking high-quality and cost-effective products.

Conclusion

The Honeycomb Stainless Steel Air Flow Straightener is a vital component in modern aerodynamic testing, offering unparalleled stability and accuracy in airflow measurement. Its advanced design, high-quality materials, and customizable specifications make it an ideal solution for a wide range of applications. By partnering with Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd., industries can ensure that their testing processes are efficient, reliable, and compliant with the highest standards of quality and performance.

As the demand for precise and reliable aerodynamic testing continues to grow, the Honeycomb Air Flow Straightener stands out as a testament to the power of innovation and engineering excellence. With its proven track record and commitment to customer satisfaction, Hengshi is well-positioned to meet the evolving needs of the industry and drive future advancements in aerodynamic technology.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025