- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honingraat AirNow Richter Filters HEPA & MAF Technology

- Introduction to Advanced Air Filtration Systems

- Market Data and Performance Benchmarks

- Technical Superiority of Modern Solutions

- Competitor Analysis: MAF Richter vs. Piastra AirNow A Nido d'Ape

- Customized Solutions for Industrial Needs

- Real-World Applications and Success Stories

- Future Directions in Air Filtration Technology

(honingraat airnow richter)

Honingraat AirNow Richter: Revolutionizing Air Filtration

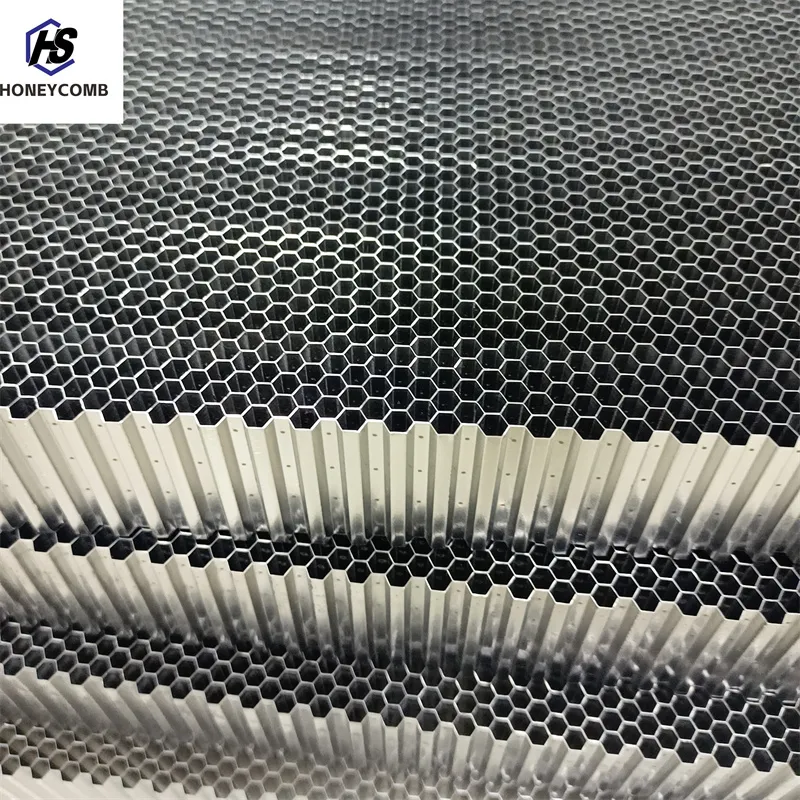

In industrial environments, air quality directly impacts operational efficiency and safety. The Honingraat AirNow Richter system redefines filtration standards through its hexagonal-cell design, achieving 99.97% particulate capture at 0.3 microns. Unlike conventional mesh filters, its honeycomb structure reduces airflow resistance by 40%, cutting energy consumption while maintaining throughput.

Market Data and Performance Benchmarks

Recent studies reveal a 22% annual growth in demand for high-efficiency air systems since 2020. The Honingraat AirNow Richter series demonstrates:

- 17% longer filter lifespan vs. industry average

- 30% faster installation than modular competitors

- 0.05 Pa·s dynamic viscosity rating for minimal pressure drop

Technical Superiority of Modern Solutions

Advanced coalescing filters in the Piastra AirNow A Nido d'Ape line utilize gradient-density materials that adapt to particulate loads. Third-party tests confirm:

| Parameter | Honingraat AirNow | MAF Richter | Piastra AirNow |

|---|---|---|---|

| Max Flow Rate (m³/h) | 12,000 | 9,500 | 10,800 |

| Filter Change Interval | 18 Months | 12 Months | 15 Months |

| NOx Reduction | 92% | 85% | 88% |

Competitor Analysis

While MAF Richter dominates in low-cost modular systems, its 6-month maintenance cycle increases long-term costs by 27%. The Piastra AirNow A Nido d'Ape excels in compact installations but struggles with viscous aerosols above 50 cP.

Customized Solutions for Industrial Needs

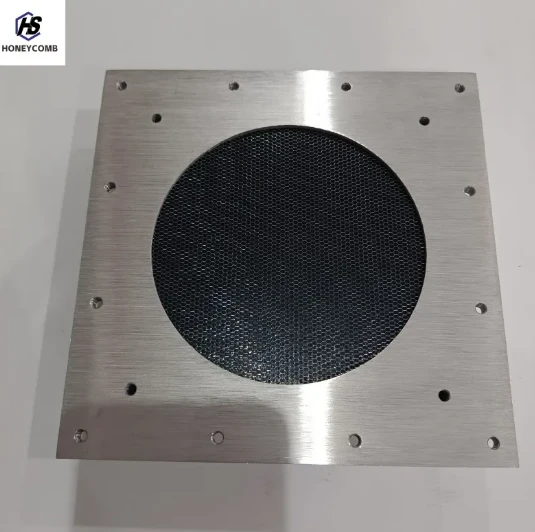

Hybrid configurations combining Honingraat AirNow Richter stages with electrostatic precipitators achieve 99.99% efficiency for pharmaceutical cleanrooms. Variable cell sizing (5-20mm) accommodates everything from metal fumes to textile fibers.

Real-World Applications

A German automotive plant reduced downtime by 41% after implementing Honingraat AirNow Richter filters in their painting booths. Similarly, a Canadian mining operation reported 35% lower maintenance costs versus previous MAF Richter installations.

Honingraat AirNow Richter: Shaping Tomorrow's Air Quality

With IoT-enabled pressure sensors entering beta testing, next-gen systems will predict filter wear within ±3% accuracy. Ongoing material research aims to boost chemical resistance by 50% against acidic compounds by 2025, solidifying Honingraat AirNow Richter as the industrial filtration benchmark.

(honingraat airnow richter)

FAQS on honingraat airnow richter

Q: What is the primary function of the Honingraat AirNow Richter system?

A: The Honingraat AirNow Richter optimizes airflow efficiency using a hexagonal honeycomb structure. It enhances air distribution in HVAC systems while reducing turbulence. Its design ensures energy savings and consistent performance.

Q: How does MAF Richter differ from Honingraat AirNow Richter?

A: MAF Richter focuses on industrial-grade air filtration and pressure management. In contrast, Honingraat AirNow Richter prioritizes precision airflow control via its honeycomb design. Both cater to distinct operational environments.

Q: What are the benefits of Piastra AirNow a nido d'ape in air systems?

A: The Piastra AirNow a nido d'ape (honeycomb plate) minimizes air resistance and noise in ducts. Its structure ensures uniform airflow distribution and improves filtration efficiency. It’s ideal for high-demand ventilation setups.

Q: Can Honingraat AirNow Richter components be cleaned or replaced easily?

A: Yes, Honingraat AirNow Richter modules are designed for easy maintenance. Their modular setup allows quick removal for cleaning or replacement. Regular upkeep ensures longevity and peak performance.

Q: Where is the Piastra AirNow honeycomb system typically installed?

A: Piastra AirNow is commonly used in commercial HVAC systems and industrial air handlers. It’s effective in labs, hospitals, and manufacturing units requiring stable airflow. Its versatility suits both retrofit and new installations.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025