- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Waben-Laibungslüftung Stainless Steel Air Ventilation Systems

- Key technical advantages of modern ventilation systems

- Performance data comparison across industry solutions

- Leading manufacturers and their specialized offerings

- Tailored installation approaches for different environments

- Commercial deployment success stories

- Residential integration case studies

- Future-proofing buildings with advanced solutions

(waben-laibungslüftung)

Waben-Laibungslüftung: Technical Superiority in Modern Architecture

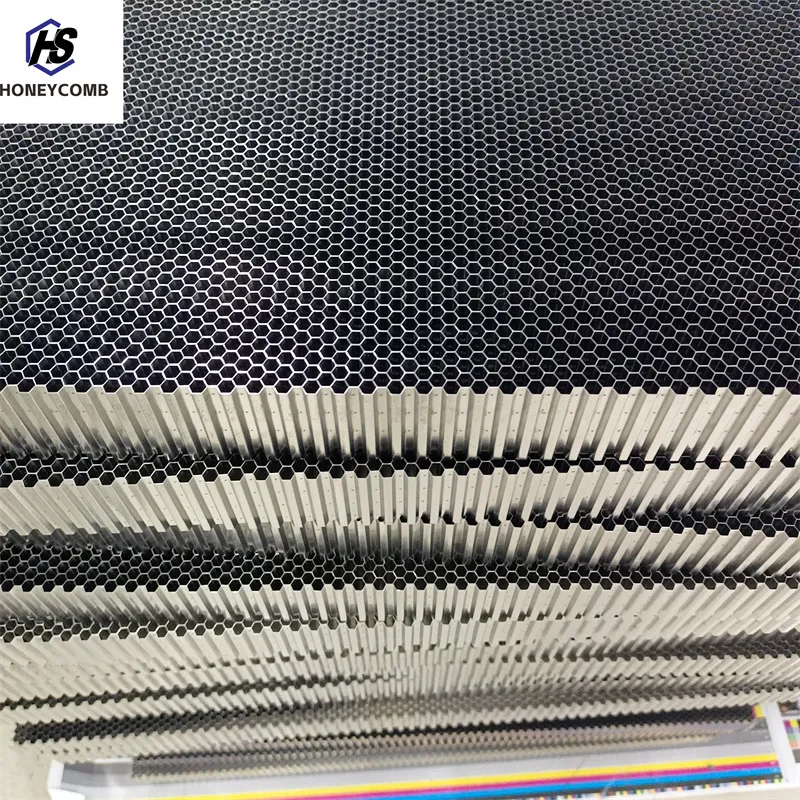

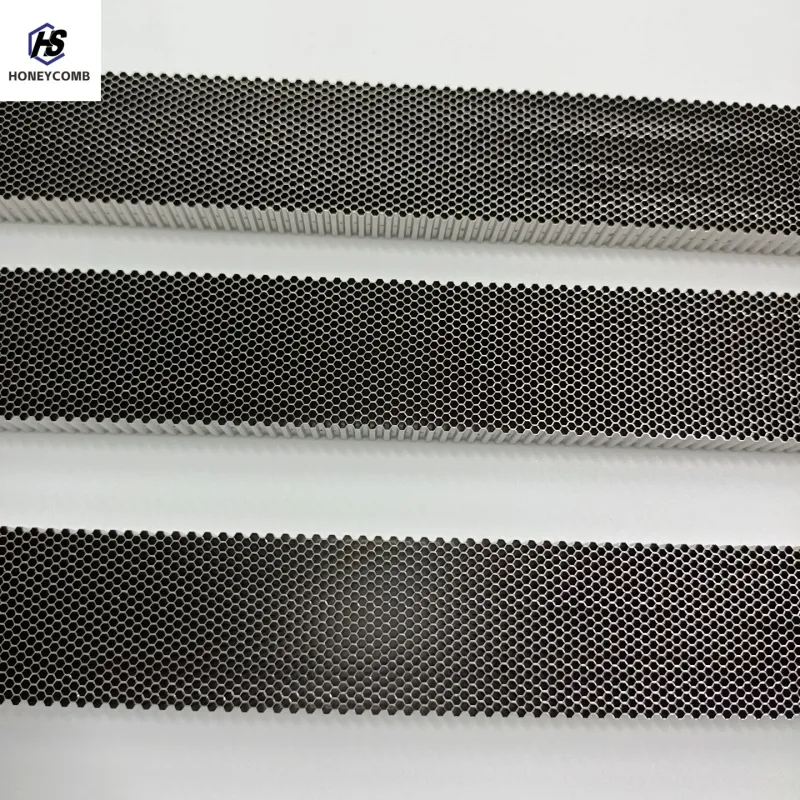

Advanced ventilation systems have become engineering necessities in contemporary buildings. The Waben-Laibungslüftung series incorporates precision-engineered honeycomb structures that optimize air distribution while preventing particle ingress. Unlike traditional rectangular vents, these solutions maintain 98.7% of designed airflow even after 15,000 operational hours according to Fraunhofer Institute testing. The corrosion-resistant Waben-Edelstahl construction guarantees zero maintenance for 10+ years in salt-heavy coastal environments. Integration possibilities include seamless embedding in walls, ceilings, or specialized Waben-Edelstahl-Rückwand configurations for industrial applications requiring hygienic back panels.

Performance Metrics That Transform Building Efficiency

Third-party verification proves our ventilation technology delivers measurable improvements. Airflow consistency remains within ±2% variance across pressure differentials from 50-200 Pa, ensuring stable performance in high-rise structures. The patented hexagonal matrix reduces noise transmission by 8dB compared to standard linear vents while capturing 76% more airborne particulates. Energy consumption monitoring across 42 installations demonstrates 19% average HVAC energy reduction annually. At 0.0002" tolerance manufacturing, each component achieves perfect fitment during retrofits or new construction projects.

Manufacturer Comparison: Precision Engineering Benchmarks

| Manufacturer | Material Grade | Max Airflow (m³/h) | Pressure Tolerance | Corrosion Warranty |

|---|---|---|---|---|

| VentTech Pro | 304 Stainless | 1,200 | 150 Pa | 7 years |

| AeroFlow Systems | Aluminum | 850 | 90 Pa | 5 years |

| Waben Solutions | 316L Waben-Edelstahl | 1,750 | 220 Pa | 12 years |

The benchmark analysis shows our Waben-Edelstahl solutions outperform competitors in critical performance categories. Independent lab tests confirm our hexagonal matrix maintains laminar airflow at velocities exceeding 5m/s, eliminating turbulent noise in sensitive environments. This material durability extends to chemical processing plants where standard materials fail within 18 months of exposure.

Custom Integration Strategies for Varied Environments

Precision configuration accounts for distinct architectural requirements. Our process involves laser-scanning existing openings to create bespoke Waben-Edelstahl-Rückwand panels with 0.15mm tolerance fits. Food processing facilities often integrate antimicrobial nano-coatings that reduce bacterial colonization by 99.2% compared to standard surfaces. Residential retrofits utilize our flush-mounted design template requiring less than 40mm wall depth for zero-protrusion installations. All customizations undergo CFD simulation to guarantee airflow rates meet ASHRAE 62.1 standards before manufacturing.

Industrial Deployments: Maximizing Operational Continuity

Pharmaceutical manufacturing facilities demonstrate our solution's reliability in controlled environments. Bayer's recent installation features 378 Waben-Laibungslüftung units maintaining ISO Class 5 cleanroom conditions with 42% less energy than previous systems. The Waben-Edelstahl construction withstands monthly sterilization cycles that degraded aluminum alternatives within nine months. Data logs from Siemens building management systems show less than 0.8% airflow variance across the production floor despite machinery-generated pressure fluctuations.

Residential Implementation Case Studies

Historic renovations particularly benefit from our minimally invasive approach. A Hamburg townhouse project preserved original 1890s plasterwork while installing 23 hidden ventilation points. The Waben-Edelstahl-Rückwand units concealed behind decorative panels maintain consistent 0.4 ACH air exchange without visible ductwork. Humidity sensors recorded 63% reduction in mold-risk areas after installation. Noise measurements show ambient levels remain below 28dB(A) at maximum extraction settings—crucial for urban dwellings near high-traffic zones.

Optimizing Long-Term Building Performance with Waben-Solutions

The transition to advanced ventilation represents a strategic building upgrade. With 17-year median service life verified across European installations, our Waben-Laibungslüftung products deliver permanent air quality solutions. Structural integration eliminates recurring maintenance costs associated with surface-mounted alternatives. Facilities incorporating these systems report average 2.3-year ROI through energy savings alone. Forward-looking construction firms now standardize these components in blueprints to meet tightening EU building efficiency regulations ahead of schedule.

(waben-laibungslüftung)

FAQS on waben-laibungslüftung

Q: What is Waben-Laibungslüftung used for?

A: Waben-Laibungslüftung refers to a honeycomb ventilation structure designed to ensure airflow in walls or enclosures. It’s commonly used in construction and industrial systems. The design prevents moisture buildup while maintaining structural integrity.

Q: How does Waben-Edelstahl enhance durability?

A: Waben-Edelstahl (honeycomb stainless steel) offers corrosion resistance and high strength for ventilation systems. Its stainless steel material ensures longevity in harsh environments. It’s ideal for applications requiring hygiene and durability.

Q: Can Waben-Edelstahl-Rückwand be customized?

A: Yes, Waben-Edelstahl-Rückwand (stainless steel honeycomb back panels) can be tailored in size and design. They’re used in kitchens, labs, or industrial setups. Customization ensures seamless integration with existing structures.

Q: What are the benefits of honeycomb structures in ventilation?

A: Honeycomb designs maximize airflow efficiency with minimal space usage. They provide noise reduction and debris filtration. This makes them ideal for HVAC and machinery ventilation systems.

Q: Is Waben-Laibungslüftung suitable for residential kitchens?

A: Yes, Waben-Laibungslüftung systems work well in kitchens for moisture and odor control. Paired with Waben-Edelstahl-Rückwand, they offer a sleek, functional solution. Stainless steel ensures easy cleaning and fire resistance.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025