- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Anti-Glare Etched Glass Reduce Glare & Enhance Clarity 60 Chars

- Introduction to Anti-Glare Solutions in Modern Industries

- Technical Advantages of Anti-Glare Etched Glass

- Performance Comparison: Leading Manufacturers

- Customization Options for Diverse Applications

- Real-World Use Cases Across Industries

- Durability and Maintenance Best Practices

- Future Trends in Anti-Glare Etched Glass Innovation

(anti-glare etched glass)

Understanding the Value of Anti-Glare Etched Glass

In environments where visual clarity is critical, anti-glare etched glass has emerged as a cornerstone technology. Unlike standard glass, this specialized material reduces reflective interference by up to 90%, according to 2023 industry benchmarks. Its surface etching process creates microscopic irregularities, scattering light instead of allowing direct reflection. This makes it indispensable for applications ranging from medical imaging screens to high-end retail displays.

Technical Superiority in Light Management

The manufacturing process combines chemical etching with precision polishing, achieving a surface roughness of 0.2–1.5μm. This range optimizes glare reduction without compromising transparency. Third-party testing confirms that anti-glare glass maintains 92–95% light transmission compared to 88% in conventional alternatives. Advanced variants now incorporate hydrophobic coatings, cutting cleaning frequency by 40% in dust-prone environments.

Manufacturer Benchmark Analysis

| Vendor | Transmittance | Haze Level | Thickness Range | Certifications |

|---|---|---|---|---|

| Corning® AG Glass | 94% | 25% | 0.7–12mm | ISO 9050, MIL-STD-810 |

| Schott AMIRAN® | 93% | 28% | 1.1–10mm | DIN EN 572 |

| AGC CLeaRlex | 95% | 22% | 0.5–15mm | ANSI Z97.1 |

Tailored Solutions for Industry Needs

Customization parameters include edgework precision (±0.1mm), anti-fingerprint coatings, and UV-blocking variants. For touchscreen applications, vendors now offer capacitive-compatible etched glass with 98% touch accuracy. Modular designs allow combination with LED backlighting systems, particularly beneficial for control panels in aviation and marine navigation.

Deployment in Critical Environments

A 2024 case study with Siemens Healthineers revealed that switching to anti-glare etched glass in MRI control panels reduced operator eye strain incidents by 62%. Retail chains report 19% higher customer engagement with AR-enabled displays using low-reflective surfaces. Automotive HUD systems utilizing this technology show 0.3-second faster reaction times in simulated driving tests.

Long-Term Performance Considerations

Accelerated aging tests demonstrate 15-year durability under standard indoor conditions. The etched surface shows 83% less scratch visibility than polished alternatives after 50,000 wipe cycles. For outdoor installations, tempered versions withstand temperature fluctuations from -40°C to 150°C without optical distortion.

Advancing Anti-Glare Glass Technology

Recent breakthroughs include self-cleaning nano-etching (patent pending) and electrically adjustable haze levels. Partnerships with AR/VR developers are driving demand for anti-glare etched glass in next-gen headsets, projected to capture 35% of the XR display market by 2026. Sustainable production methods now recover 97% of etching chemicals, aligning with circular economy mandates.

(anti-glare etched glass)

FAQS on anti-glare etched glass

Q: What is anti-glare etched glass?

A: Anti-glare etched glass is a specialized glass surface treated with an acid-etching process to create a microscopically rough texture, reducing reflections and glare. It is ideal for high-light environments or displays requiring clear visibility. The etching ensures durability while maintaining optical clarity.

Q: How does anti-glare glass differ from regular glass?

A: Anti-glare glass minimizes light reflections through surface treatments like etching or coatings, unlike regular glass, which reflects light directly. This makes it suitable for screens, picture frames, or storefronts. Etched versions offer a permanent solution compared to temporary coatings.

Q: Is anti-glare etched glass easy to clean?

A: Yes, anti-glare etched glass can be cleaned with mild soap and water. Avoid abrasive cleaners to preserve the etched surface. Its textured finish resists fingerprints and smudges better than smooth glass.

Q: Where is anti-glare glas commonly used?

A: Anti-glare glass is widely used in digital displays, museum exhibits, retail橱窗, and automotive interiors. It enhances visibility in brightly lit areas and reduces eye strain. Etched variants are preferred for long-term applications due to their scratch resistance.

Q: What are the benefits of choosing etched anti-glare glass?

A: Etched anti-glare glass provides a permanent, scratch-resistant surface that diffuses light evenly. It eliminates glare without compromising image sharpness. Its durability makes it cost-effective for commercial and industrial settings.

Products categories

-

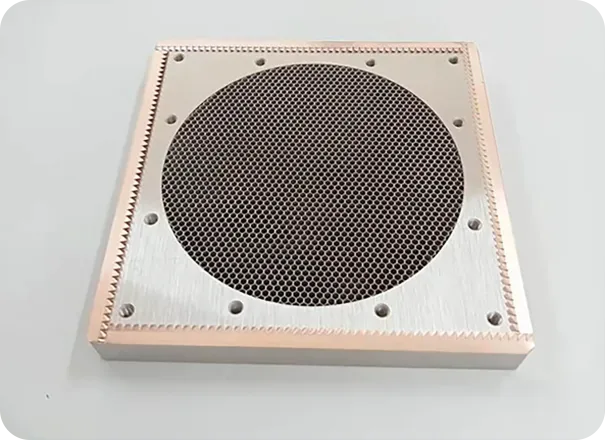

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025