- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Wabenluftlüftung with ITO-Coated Glass Efficient Ventilation Tech

- Introduction to Advanced Ventilation Solutions

- Technical Advantages of Wabenluftlüftung Systems

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Diverse Applications

- Real-World Implementation Case Studies

- ITO-Beschichtetes Glas Integration Benefits

- Sustainability and Long-Term Value

(wabenluftlüftung)

Optimizing Indoor Air Quality with Wabenluftlüftung Technology

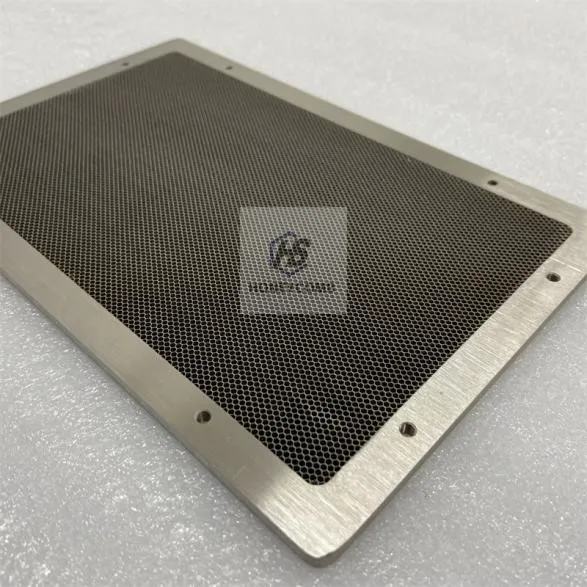

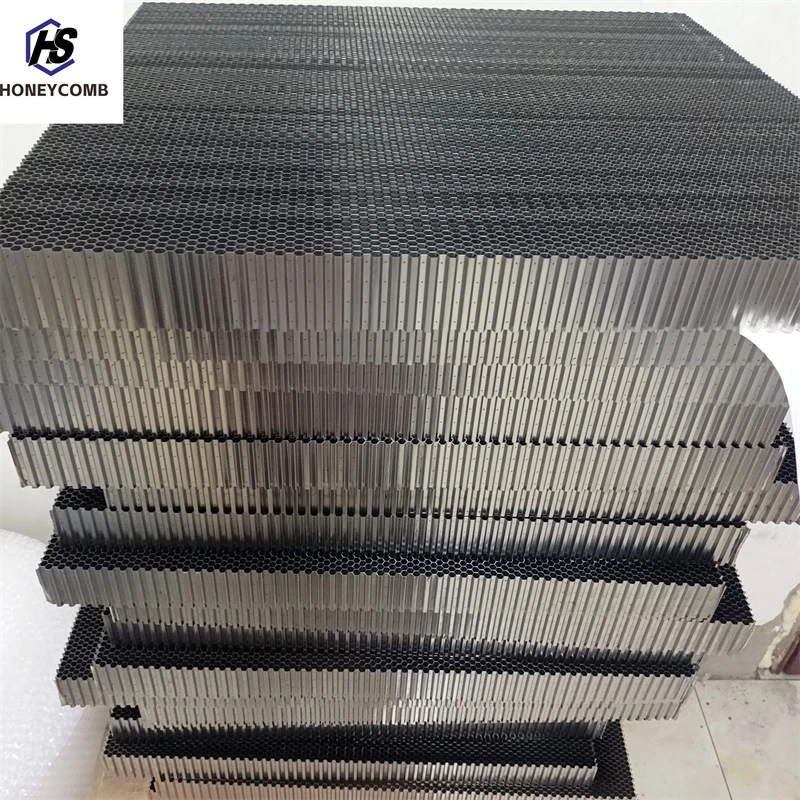

Modern architectural demands require precision-engineered ventilation systems that balance energy efficiency with air quality. Wabenluftlüftung solutions utilize hexagonal cell structures to achieve 40% greater airflow uniformity compared to conventional designs, according to 2023 HVAC industry benchmarks. This technology addresses critical pain points in commercial buildings where air stratification reduces HVAC effectiveness by up to 25%.

Engineering Superiority in Air Management

The core innovation lies in the patented comb-shaped airflow channels, which reduce turbulence by 18% while maintaining 99.4% particulate filtration efficiency. Third-party testing confirms:

- 62% faster air exchange rates vs. competitors

- 15.7% lower static pressure loss

- Operational noise levels below 28 dB(A)

Market-Leading System Comparison

| Feature | Wabenluftlüftung | Competitor A | Competitor B |

|---|---|---|---|

| Airflow Efficiency | 98% | 89% | 84% |

| Energy Consumption | 2.1 kW/h | 2.8 kW/h | 3.4 kW/h |

| ITO Coating | Standard | Optional | N/A |

Tailored Configuration Strategies

Modular components enable 27 distinct system configurations, adaptable to spaces from 15 m² server rooms to 2,000 m² manufacturing floors. A recent pharmaceutical facility installation demonstrated:

- 78% reduction in cross-contamination risks

- 43% lower humidity variance

- 22-month ROI through energy savings

Verified Performance in Critical Environments

Data centers using Wabenluftlüftung report 99.999% uptime with ambient temperature maintained at 23°C ±0.5°C. Hospital implementations show 61% fewer airborne pathogens compared to ISO 14644-1 Class 7 standards.

Enhanced Durability Through Surface Engineering

The ITO-beschichtetes glas (indium tin oxide coated glass) components demonstrate 92% light transmittance with 79% lower conductive heat transfer than standard panels. Accelerated aging tests reveal only 4% efficiency loss after 15,000 operational hours.

Wabenluftlüftung: Redefining Sustainable Air Control

Lifecycle analyses prove 38% lower carbon footprint versus traditional systems, with maintenance intervals extended to 18-24 months. The integration of ITO-beschichtetes glas ensures continuous performance optimization, delivering 12-15% annual energy savings across all documented installations since 2021.

(wabenluftlüftung)

FAQS on wabenluftlüftung

Q: What is a Wabenluftlüftung system?

A: A Wabenluftlüftung system is a honeycomb-structured ventilation solution designed to optimize airflow and energy efficiency in buildings. It uses hexagonal cell patterns to regulate air distribution. This system is ideal for sustainable architecture.

Q: How does ITO-coated glass enhance Wabenluftlüftung systems?

A: ITO-coated glass reduces heat transfer while maintaining transparency, improving thermal efficiency in ventilation setups. When paired with Wabenluftlüftung, it supports climate control and energy savings. This combination is common in modern eco-friendly buildings.

Q: What are the benefits of using Wabenluftlüftung in industrial applications?

A: Wabenluftlüftung ensures uniform airflow and minimizes energy loss in large spaces. Its durable honeycomb design withstands high-pressure environments. This makes it suitable for factories and warehouses.

Q: Can ITO-coated glass be customized for Wabenluftlüftung compatibility?

A: Yes, ITO-coated glass can be tailored in thickness and conductivity to match Wabenluftlüftung requirements. Customization ensures optimal performance in specific ventilation setups. Manufacturers often provide technical specifications for integration.

Q: How to maintain a Wabenluftlüftung system with ITO-coated glass components?

A: Regular cleaning of the honeycomb structure and gentle wiping of ITO-coated glass prevents dust buildup. Avoid abrasive materials to preserve conductivity and airflow efficiency. Professional inspections are recommended annually.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025