- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Precision Wind Tunnel Honeycomb for Air Flow Straightening

In the intricate world of aerodynamics, precision is paramount. Every whisper of air, every subtle current, can significantly influence the outcome of critical research and product development. This is where the often-understated yet profoundly impactful technology of wind tunnel honeycomb comes into play. Far more than just a structural component, these sophisticated flow straighteners are the silent architects of laminar flow, transforming turbulent air into a controlled, uniform stream essential for accurate experimental results. From aerospace engineering to automotive design, and from civil infrastructure to sports equipment, the effectiveness of a wind tunnel hinges on the quality and design of its internal air flow straightener.

The demand for more precise and efficient aerodynamic testing continues to grow. This trend drives innovation in the design and manufacturing of components like the wind tunnel honeycomb, pushing for materials with superior strength-to-weight ratios, enhanced durability, and the ability to withstand extreme environmental conditions. As industries strive for greater energy efficiency, reduced drag, and improved performance, the role of a perfectly conditioned airflow within a test environment becomes ever more critical. This comprehensive guide delves into the technical intricacies, application benefits, and manufacturing excellence behind modern honeycomb in wind tunnel systems, focusing on how leading solutions like the Hengshi Honeycomb Customized Honeycomb Air Straightenerflow Straightener are setting new industry benchmarks.

Understanding Wind Tunnel Honeycomb: Technical Parameters and Advantages

A wind tunnel honeycomb is essentially a matrix of thin-walled cells, typically hexagonal or square, designed to rectify airflow. Its primary function is to eliminate large-scale turbulence and ensure a highly uniform velocity profile entering the test section of a wind tunnel. This homogenization of the airflow is crucial for obtaining repeatable and accurate experimental data, enabling engineers and researchers to precisely evaluate aerodynamic forces, pressure distributions, and flow phenomena around tested models. Without an effective air flow straightener, the raw, turbulent air from the fan would render any experimental data unreliable and inconsistent.

Key technical parameters define the performance and applicability of a wind tunnel honeycomb:

- Cell Size (D): The diameter or side length of an individual cell. Smaller cells generally lead to finer flow straightening but can increase pressure drop.

- Length (L): The depth of the honeycomb block. A greater L/D ratio (length-to-diameter ratio) enhances flow straightening by allowing more flow development within the cells, but also increases material cost and pressure drop. Typical L/D ratios range from 6 to 10 for optimal performance.

- Material: Common materials include aluminum, stainless steel, fiberglass, and various composites. The choice depends on factors like weight, corrosion resistance, temperature stability, and cost.

- Open Area Ratio: The percentage of the honeycomb's frontal area that is open for airflow. A higher open area minimizes pressure drop.

- Wall Thickness: The thickness of the cell walls. Thinner walls reduce blockage and pressure drop but can compromise structural integrity.

- Pressure Drop: The reduction in static pressure across the honeycomb. Minimizing pressure drop is vital for energy efficiency in large wind tunnel operations.

The advantages of integrating a high-quality honeycomb in wind tunnel systems are manifold:

- Laminar Flow Generation: Transforms turbulent flow into smooth, laminar streamlines, crucial for accurate aerodynamic testing.

- Turbulence Reduction: Significantly diminishes the intensity and scale of turbulence, ensuring consistent flow conditions.

- Flow Uniformity: Creates a highly uniform velocity profile across the entire test section, preventing skewed results.

- Energy Efficiency: While causing some pressure drop, a well-designed honeycomb optimizes the overall energy use of the wind tunnel by minimizing the energy lost to chaotic turbulence.

- Structural Integrity: Provides robust support within the flow conditioning section, contributing to the overall stability of the tunnel structure.

- Noise Reduction: By streamlining airflow, it can contribute to reducing aerodynamic noise generated within the tunnel.

Hengshi Honeycomb offers the Hengshi Honeycomb Customized Honeycomb Air Straightenerflow Straightener, engineered to meet the stringent demands of modern aerodynamic research and industrial applications. Our products are meticulously designed to optimize the balance between flow straightening efficiency and minimal pressure loss, ensuring superior performance for your specific needs.

Key Parameters of Wind Tunnel Honeycomb

| Parameter | Typical Range/Value | Impact on Performance |

|---|---|---|

| Cell Size (D) | 3 mm to 25 mm (0.125" to 1") | Smaller cells enhance flow straightening, larger cells reduce pressure drop. |

| Length (L) | 50 mm to 300 mm (2" to 12") | Longer sections improve flow uniformity and turbulence reduction. |

| L/D Ratio | 6:1 to 15:1 | Higher ratios yield better flow straightening, with diminishing returns beyond 10-12:1. |

| Wall Thickness | 0.05 mm to 0.2 mm (0.002" to 0.008") | Thinner walls reduce blockage and pressure drop. |

| Material | Aluminum, Stainless Steel, Fiberglass, Carbon Fiber | Affects weight, strength, corrosion resistance, temperature limits. |

| Open Area Ratio | Typically > 95% | Higher ratio minimizes pressure drop and airflow restriction. |

| Turbulence Reduction | Can reduce turbulence intensity by 50-90% | Directly impacts data accuracy and repeatability. |

| Pressure Drop Coefficient | 0.05 to 0.2 (dimensionless) | Lower values indicate higher energy efficiency. |

Hengshi Honeycomb: Product Specifications and Core Technologies

The Hengshi Honeycomb Customized Honeycomb Air Straightenerflow Straightener is a testament to precision engineering and material science. Our commitment to excellence ensures that each unit delivers optimal performance in the most demanding applications. Product URL: https://www.hshihoneycomb.com/hengshi-honeycomb-customized-hone.html.

Material Excellence

The choice of material for a wind tunnel honeycomb is critical, influencing its performance, lifespan, and suitability for specific environments. Hengshi Honeycomb utilizes a range of high-quality materials to meet diverse application requirements:

- Aluminum Alloy: Lightweight, excellent thermal conductivity, good corrosion resistance (especially anodized), and cost-effective. Ideal for general-purpose wind tunnels and aerospace applications where weight is a concern. Our aluminum honeycombs are typically made from 3003, 5052, or 5056 alloys, offering varying degrees of strength and corrosion resistance.

- Stainless Steel: Superior corrosion resistance, high strength, and excellent temperature stability. Perfect for environments with high humidity, corrosive gases, or elevated temperatures, commonly found in petrochemical, metallurgical, and marine applications. We use grades like 304 and 316 for enhanced durability.

- Fiberglass (FRP/GRP): Non-metallic, non-conductive, excellent corrosion resistance to a wide range of chemicals, and good strength-to-weight ratio. Ideal for applications requiring electrical insulation or resistance to harsh chemical environments, such as certain industrial exhaust systems or specialized research facilities.

- Carbon Fiber Composites: Extremely high strength-to-weight ratio, excellent stiffness, and fatigue resistance. While more expensive, they are chosen for cutting-edge research wind tunnels where absolute minimal weight and maximum rigidity are required.

Manufacturing Processes: Precision at Every Step

The production of a high-performance wind tunnel honeycomb involves a meticulous multi-stage process, ensuring precision, uniformity, and structural integrity. Hengshi Honeycomb employs advanced manufacturing techniques, including:

- Material Preparation: High-grade raw materials are selected based on the specific application requirements. For metallic honeycombs, thin foils are precisely cut to size.

- Corrugation: The metal foils or composite sheets are fed through specialized machinery that forms them into a corrugated, wavy pattern. This step is critical for defining the cell size and geometry.

- Bonding/Brazing: The corrugated sheets are then assembled and bonded together. For aluminum, a specialized adhesive film is typically used, cured under heat and pressure. For stainless steel, high-temperature brazing or welding techniques may be employed for maximum structural integrity. This forms the continuous "block" of honeycomb.

- Block Expansion (for unexpanded blocks): Some honeycomb is supplied in an unexpanded block form. In this case, the block is mechanically expanded to reveal the hexagonal or square cells.

- Slicing/Cutting: The large honeycomb block is then precisely sliced to the desired thickness (length of the honeycomb) using high-precision CNC cutting machines. This ensures uniform height and parallelism.

- Edge Framing/Reinforcement: For wind tunnel applications, the honeycomb panel is often fitted with a sturdy frame (e.g., aluminum or stainless steel) around its perimeter. This frame facilitates easier installation, provides structural support, and prevents damage to the delicate honeycomb edges. Precision CNC machining is often used for creating custom frames.

- Surface Treatment: Depending on the material, surface treatments like anodizing (for aluminum) or passivation (for stainless steel) may be applied to enhance corrosion resistance or improve surface hardness.

- Quality Control & Inspection: Each wind tunnel honeycomb undergoes rigorous inspection. This includes dimensional checks (cell size, length, flatness, perpendicularity), visual inspection for defects, and sometimes even airflow uniformity testing. We adhere to strict internal quality protocols and industry standards.

Image: Close-up of precisely manufactured honeycomb cells, showcasing the meticulous craftsmanship involved in producing a high-quality wind tunnel honeycomb.

Detection Standards and Lifespan

Quality assurance is paramount. Our manufacturing processes and products conform to international standards, including ISO 9001:2015 for quality management systems. Individual product specifications often align with ANSI (American National Standards Institute) and ASTM (American Society for Testing and Materials) guidelines for material properties and testing methodologies. For instance, ASTM C271/C271M provides test methods for density of core materials, crucial for verifying honeycomb specifications.

The lifespan of a wind tunnel honeycomb can extend for decades, particularly when manufactured from durable materials like stainless steel or appropriately treated aluminum, and used within its specified operating conditions. Factors influencing longevity include exposure to corrosive elements, extreme temperatures, mechanical stress, and proper handling during installation and maintenance. Our robust designs ensure exceptional durability and resistance to typical operational stresses.

Product Advantages: Energy Efficiency and Corrosion Resistance

The Hengshi Honeycomb Customized Honeycomb Air Straightenerflow Straightener brings tangible benefits to its users:

- Enhanced Energy Efficiency: By significantly reducing turbulence and ensuring a highly uniform flow, our honeycombs minimize energy losses within the wind tunnel, allowing the fan system to operate more efficiently. This translates directly into lower operational costs and reduced carbon footprint.

- Superior Corrosion Resistance: With options in aluminum (anodized for protection), stainless steel, and fiberglass, our products are engineered to withstand harsh environmental conditions, including high humidity, chemical exposure (e.g., in industrial exhaust systems), and salt spray, ensuring long-term performance and reduced maintenance.

- Reduced Vibrations and Noise: A well-straightened airflow inherently reduces pneumatic noise and vibrations generated by turbulent flow, leading to a quieter operating environment and potentially less structural fatigue on the wind tunnel itself.

Applications of Honeycomb in Wind Tunnels: Real-World Impact

The application of a wind tunnel honeycomb extends across a broad spectrum of industries, playing a vital role in research, development, and quality control. Its ability to create a precisely controlled airflow environment is indispensable for accurate data acquisition.

- Aerospace Industry: This is arguably the most prominent application. From designing new aircraft wings to testing satellite re-entry vehicles, precise aerodynamic data is critical. Honeycomb in wind tunnel facilities ensures accurate measurement of lift, drag, and moments, enabling engineers to optimize designs for fuel efficiency, speed, and safety.

- Automotive Industry: Modern vehicle design heavily relies on wind tunnel testing to optimize aerodynamics for improved fuel economy, reduced wind noise, and enhanced stability at high speeds. Honeycombs are crucial for simulating consistent road conditions and accurately measuring drag coefficients on vehicles ranging from passenger cars to Formula 1 racers.

- Civil Engineering & Architecture: Wind tunnels are used to test the aerodynamic stability of tall buildings, bridges, and other large structures against strong winds, preventing resonance and structural failure. The air flow straightener ensures realistic wind profiles are applied to scaled models.

- Sports Aerodynamics: From cycling helmets to Olympic bobsleds, and from golf balls to ski jumps, athletes and equipment manufacturers use wind tunnels to gain a competitive edge by optimizing designs for minimal drag and maximum performance.

- Environmental Testing: Wind tunnels equipped with honeycombs are used to study pollutant dispersion, the effects of wind on solar panels, and the performance of wind turbines. The controlled flow allows for precise simulation of environmental conditions.

- HVAC Systems: For testing the efficiency and noise levels of fans, blowers, and air conditioning units, controlled airflow is essential. Honeycomb panels help standardize test conditions.

- Industrial Processes: In industries like petrochemicals, metallurgy, and water treatment, precise flow control is necessary for optimizing mixing, heat exchange, and combustion processes. While not always directly in "wind tunnels," similar flow conditioning principles apply, often using honeycomb structures as flow straighteners or flame arrestors.

The impact of a high-quality honeycomb in wind tunnel applications is profound. It directly contributes to:

- Reduced Development Cycles: Accurate data means fewer iterations and faster refinement of designs.

- Cost Savings: Optimizing designs for efficiency translates into lower material consumption and operational costs in the final product.

- Enhanced Safety: Thorough aerodynamic testing ensures products meet safety standards under various conditions.

- Improved Performance: Whether it's a faster aircraft or a more fuel-efficient car, superior aerodynamic design directly impacts performance metrics.

Industry Landscape: Manufacturer Comparison and Market Trends

The market for wind tunnel honeycomb and related flow conditioning products is served by a few specialized manufacturers, each with their own strengths. While some offer off-the-shelf solutions, others, like Hengshi Honeycomb, excel in customized, high-precision engineering. Choosing the right manufacturer is crucial, as the quality of the flow straightener directly impacts the validity of wind tunnel test results.

Illustrative Manufacturer Comparison (Hengshi Focus)

| Feature | Hengshi Honeycomb | Typical Competitor A (Generalist) | Typical Competitor B (Specialist) |

|---|---|---|---|

| Customization Capabilities | High (tailored cell size, L/D, material, framing) | Moderate (standard sizes, limited materials) | High (but potentially longer lead times) |

| Material Range | Aluminum, Stainless Steel, Fiberglass, Carbon Fiber | Aluminum, some Steel | Aluminum, Steel, specific Composites |

| Quality Control & Certifications | ISO 9001, rigorous internal QC, adherence to ASTM/ANSI | Basic QC, some general certifications | Strong QC, often niche certifications |

| Engineering Support | Extensive pre-sales consultation, design assistance | Standard product support | Good technical support |

| Delivery Lead Time | Optimized for custom orders, transparent timelines | Standard for stock items, longer for custom | Can be long for highly specialized items |

| Cost-Effectiveness (for custom solutions) | High value for precision and customization | Lower for standard, higher for limited custom | Premium pricing for high specialization |

| Application Focus | Aerospace, Automotive, Industrial, Research | General industrial flow control | Specific wind tunnel projects |

Hengshi's Unique Selling Propositions:

- Unrivaled Customization: We don't just offer standard sizes; we engineer the wind tunnel honeycomb to your exact specifications, including unique cell geometries, L/D ratios, exotic materials, and custom framing, ensuring perfect integration and optimal performance within your specific wind tunnel design.

- Precision Manufacturing: Our state-of-the-art facilities and experienced technicians ensure every component meets the tightest tolerances, resulting in superior flow straightening capabilities.

- Comprehensive Material Expertise: Our in-depth knowledge of various materials allows us to recommend and manufacture the most suitable honeycomb for your environment, whether it demands lightweight properties, extreme corrosion resistance, or high-temperature stability.

- Dedicated Engineering Support: From initial concept and design consultation to post-installation support, our team of experts works closely with clients to deliver solutions that precisely meet their aerodynamic testing challenges.

- Adherence to Global Standards: Our commitment to ISO 9001 and industry-specific standards ensures that every product leaving our facility is of the highest quality and reliability.

Emerging Trends in Wind Tunnel Technology:

- Smart Integration: Future honeycomb in wind tunnel systems may incorporate sensors for real-time flow monitoring, allowing for adaptive flow conditioning.

- Additive Manufacturing: While currently challenging for large-scale honeycomb, 3D printing could enable even more complex and optimized internal structures in the future.

- Advanced Hybrid Materials: Combining properties of different materials to achieve unprecedented strength-to-weight ratios and environmental resistance.

- Larger Scale Testing: As engineering projects grow in size and complexity, so does the need for larger, more robust wind tunnels, requiring equally robust and scalable air flow straightener solutions.

Customized Solutions and Project Implementation

Every wind tunnel is unique, with specific dimensions, operating conditions, and aerodynamic objectives. Off-the-shelf solutions often compromise performance. This is where Hengshi Honeycomb's strength in delivering customized wind tunnel honeycomb truly shines. Our process is designed to seamlessly integrate our expertise with your project's specific demands.

Our Customization Process:

- Initial Consultation & Requirements Gathering: We begin by understanding your wind tunnel's specifications, including dimensions, desired airflow velocity, maximum allowable pressure drop, operating temperature range, environmental factors (e.g., humidity, corrosive agents), and specific research objectives. This phase involves close collaboration with your engineers and project managers.

- Conceptual Design & Material Selection: Based on the gathered data, our engineering team proposes optimal honeycomb parameters (cell size, L/D ratio, length, wall thickness) and material choices (aluminum, stainless steel, fiberglass, etc.). We consider the trade-offs between performance, cost, and durability to recommend the best solution.

- Detailed Engineering & CAD Modeling: Once the conceptual design is approved, we develop detailed engineering drawings and 3D CAD models of the wind tunnel honeycomb and its custom framing. This includes precise specifications for mounting interfaces and integration points within your existing tunnel structure.

- Prototyping & Testing (if required): For highly specialized or novel applications, we can produce prototypes for preliminary testing and validation, ensuring the design meets performance expectations before full-scale production.

- Precision Manufacturing: Utilizing our advanced production lines, we manufacture the honeycomb to exact specifications. Our rigorous quality control ensures dimensional accuracy, cell integrity, and consistent material properties.

- Quality Assurance & Final Inspection: Each finished air flow straightener undergoes a comprehensive inspection, including dimensional verification, visual checks for defects, and sometimes even localized airflow straightener tests to guarantee performance.

- Packaging & Delivery: Custom-designed packaging ensures the safe transportation of your honeycomb panel, protecting it from damage during transit to your facility, whether domestic or international.

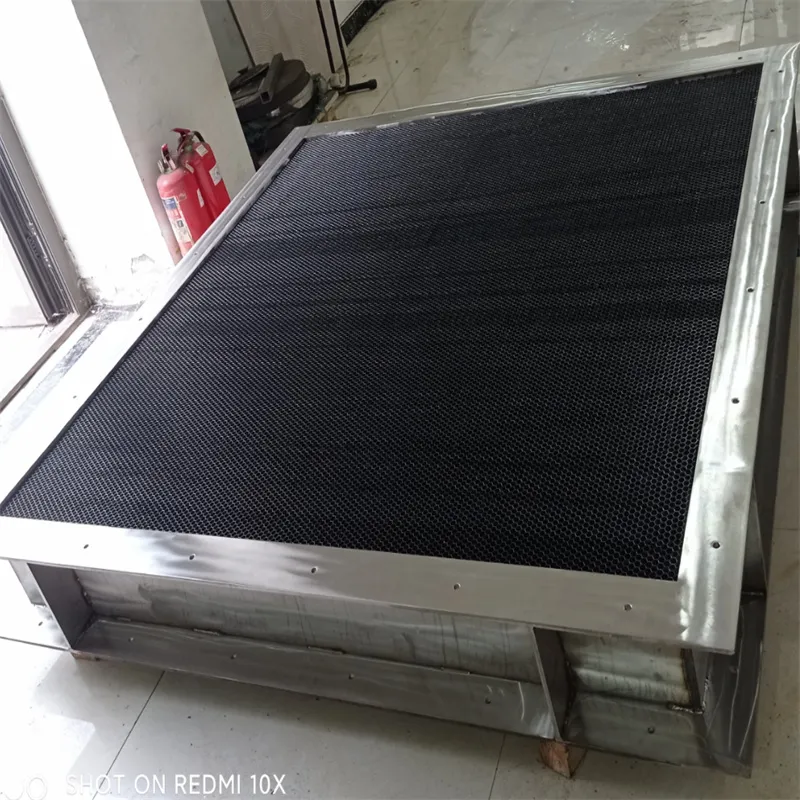

Image: A large, customized wind tunnel honeycomb panel ready for installation, highlighting the scale and precision achievable for bespoke aerodynamic testing facilities.

Delivery Cycle Explanation

The delivery cycle for a Customized Honeycomb Air Straightenerflow Straightener varies depending on the complexity of the design, the chosen material, and the order volume. Typically, the process can be broken down as follows:

- Design & Approval Phase: 1-2 weeks (for standard customizations) to 3-4 weeks (for complex, novel designs). This includes consultations, drawing creation, and client approval.

- Material Procurement: 1-3 weeks, depending on the availability of specialized materials.

- Manufacturing: 3-6 weeks, depending on the size and quantity of the honeycomb panels and current production load. Precision processes require dedicated time.

- Quality Control & Packaging: 1-2 days.

- Shipping: Varies greatly by destination and shipping method (air freight vs. sea freight).

Overall, a typical custom order might take anywhere from 6 to 12 weeks from initial consultation to ex-works shipment. We provide clear, transparent timelines at the quoting stage, and our project managers keep clients informed at every step of the process.

Quality Assurance and Customer Trust

At Hengshi Honeycomb, trust is built on a foundation of unwavering quality. Our commitment to delivering superior wind tunnel honeycomb products is underpinned by rigorous quality assurance protocols, comprehensive certifications, and dedicated customer support. We understand that the reliability of your research and development hinges on the precision of our products.

Commitment to Quality Control

Our quality control system encompasses every stage of the manufacturing process:

- Raw Material Inspection: All incoming materials are thoroughly inspected to ensure they meet specified chemical compositions, mechanical properties, and dimensional tolerances. We only source from reputable suppliers.

- In-Process Monitoring: Critical manufacturing steps, such as corrugation, bonding, and slicing, are continuously monitored for precision and consistency. Automated and manual checks are performed to detect any deviations early.

- Dimensional Accuracy Verification: Using advanced measurement tools, we verify the cell size, length, overall dimensions, flatness, and perpendicularity of each air flow straightener to ensure it conforms exactly to engineering drawings. This is particularly vital for the performance of a honeycomb in wind tunnel applications.

- Visual and Structural Integrity Checks: Each panel undergoes thorough visual inspection for any surface imperfections, unbonded areas, or structural flaws. Load-bearing and deflection tests may be conducted for specific applications.

- Performance Testing (Optional): While full-scale wind tunnel testing is typically done by the client, we can, upon request, provide certain in-house tests related to pressure drop or airflow resistance of small samples, though this is usually simulated based on design.

Certifications and Industry Recognition

Hengshi Honeycomb operates under an ISO 9001:2015 certified Quality Management System. This globally recognized standard demonstrates our commitment to consistent quality, customer satisfaction, and continuous improvement. Our adherence to this standard means that every aspect of our operations, from design and production to sales and customer service, is managed with a focus on excellence.

Furthermore, our products are designed and tested in alignment with relevant industry standards such as ASTM International and ANSI (American National Standards Institute) guidelines where applicable, particularly concerning material specifications and mechanical properties.

Warranty and After-Sales Support

We stand by the quality of our Hengshi Honeycomb Customized Honeycomb Air Straightenerflow Straightener. All products come with a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. Our warranty terms are transparent and provided with every quotation.

Our commitment extends beyond delivery. We offer dedicated after-sales support to address any queries regarding installation, maintenance, or performance. Our technical team is available to provide guidance and troubleshoot any issues, ensuring that your wind tunnel honeycomb continues to perform optimally throughout its lifespan. Customer satisfaction is our top priority, and we strive to build long-term partnerships based on trust and reliable service.

Manufacturing Process Explained: From Raw Material to Precision Flow Straightener

The journey of raw material transforming into a high-performance wind tunnel honeycomb is a fascinating display of precision engineering. Here's a detailed look at the typical manufacturing process, highlighting key steps and technologies involved:

Step 1: Raw Material Preparation & Slitting

It all begins with selecting the highest quality raw materials – typically thin foils of aluminum (e.g., 3003, 5052, 5056 alloys) or stainless steel (e.g., 304, 316 grades), or pre-impregnated composite sheets. These materials arrive in large coils. The first step involves precise slitting of these coils into narrower strips of specific widths, which will define the height of the future honeycomb cells.

Step 2: Corrugation

The slit material strips are then fed into a specialized corrugation machine. This machine uses precision rollers to form the flat strips into a wavy, sinusoidal, or specific geometric profile. The height and pitch of these waves determine the final cell size and shape (e.g., hexagonal, square). This is a critical step as it establishes the fundamental geometry of the air flow straightener.

Step 3: Adhesive Application or Brazing Prep

For aluminum honeycombs, a thin, pre-applied adhesive film is typically used. This film is strategically placed on the corrugated strips. For stainless steel, the surfaces might be prepared for high-temperature brazing or welding. The goal is to ensure strong, consistent bonds between the corrugated layers.

Step 4: Assembly & Stacking

The corrugated strips, now with adhesive or ready for bonding, are meticulously stacked one on top of another. Each subsequent strip is offset to create the characteristic hexagonal or square pattern when viewed from the end. This stacking process requires high precision to ensure perfect alignment and uniform cell formation throughout the block.

Step 5: Curing/Brazing (Block Formation)

Once stacked, the entire assembly is placed into a curing oven or brazing furnace. For adhesive-bonded aluminum, controlled heat and pressure are applied to activate and cure the adhesive, forming a solid, rigid block of unexpanded honeycomb. For stainless steel, brazing alloys melt and flow, creating metallurgical bonds between the layers at high temperatures. This stage creates the raw honeycomb block.

Step 6: Slicing/Cutting to Length

The cured or brazed honeycomb block is then precisely sliced to the desired thickness, which corresponds to the "length" (L) of the final honeycomb in wind tunnel product. This is done using high-precision bandsaws or CNC cutting machines equipped with specialized blades to minimize burrs and maintain cell integrity. The cut surfaces must be perfectly parallel to ensure uniform flow. This step directly defines the L/D ratio of the final product.

Step 7: Expansion (if applicable)

Some honeycomb is manufactured and shipped in an unexpanded "block" form to save space. If so, at this stage, the block is mechanically expanded to open up the individual cells, revealing the hexagonal matrix. This step requires careful handling to avoid deforming the cell walls.

Step 8: Edge Framing & Customization

For wind tunnel applications, the honeycomb panel is typically encased in a rigid frame (e.g., aluminum or stainless steel) that matches the dimensions of the wind tunnel's flow conditioning section. This frame is often CNC machined for a perfect fit and provides structural support, protection for the delicate cell edges, and facilitates easy installation. Any specialized mounting brackets or features are also added at this stage.

Step 9: Cleaning & Surface Treatment

The finished wind tunnel honeycomb might undergo cleaning to remove any debris or residues from manufacturing. Depending on the material and application, surface treatments like anodizing (for aluminum to enhance corrosion resistance and hardness) or passivation (for stainless steel to improve corrosion resistance) are applied.

Step 10: Final Inspection & Packaging

Before shipment, each honeycomb panel undergoes a final, comprehensive quality inspection. This includes checks for dimensional accuracy, cell integrity, bond strength, surface finish, and overall craftsmanship. Once approved, the product is carefully packaged using protective materials to prevent damage during transit, ensuring it arrives at your facility in perfect condition.

Image: An automated manufacturing line demonstrating the precision and scale involved in producing high-volume, high-quality wind tunnel honeycomb for various industrial and research applications.

Frequently Asked Questions (FAQ) about Wind Tunnel Honeycomb

-

What is the primary function of a wind tunnel honeycomb?

The primary function of a wind tunnel honeycomb is to straighten and condition the airflow, transforming turbulent, chaotic flow into a smooth, uniform, and laminar stream. This ensures that the air entering the test section has a consistent velocity profile and minimal turbulence, which is crucial for obtaining accurate and repeatable aerodynamic test data. It essentially acts as an air flow straightener. -

What materials are commonly used for wind tunnel honeycombs, and why?

Common materials include aluminum (lightweight, good thermal conductivity, cost-effective), stainless steel (high strength, excellent corrosion resistance, high temperature stability), and fiberglass (non-conductive, excellent chemical resistance, good strength-to-weight ratio). The choice depends on specific application requirements such as weight constraints, environmental conditions (e.g., humidity, corrosive agents), temperature range, and budget. -

How does cell size and L/D ratio (Length-to-Diameter ratio) affect honeycomb performance?

Smaller cell sizes (D) generally lead to better flow straightening and turbulence reduction because they break down smaller eddies more effectively. However, they also increase pressure drop across the honeycomb. The L/D ratio significantly impacts performance: a higher L/D ratio (typically 6:1 to 15:1) allows the flow more distance to align within the cells, resulting in superior flow uniformity and turbulence reduction. Optimizing these parameters is key to balancing performance and energy efficiency. -

What inspection standards should a high-quality wind tunnel honeycomb meet?

A high-quality wind tunnel honeycomb should meet stringent internal quality control standards and ideally conform to international norms like ISO 9001 for quality management. Specific product parameters and material properties often adhere to standards from organizations such as ASTM International (e.g., ASTM C271/C271M for core density) and ANSI (American National Standards Institute) for dimensional tolerances and mechanical testing. -

Can honeycomb panels be customized for specific wind tunnel dimensions?

Absolutely. Customization is a key aspect of high-performance wind tunnel honeycomb solutions. Manufacturers like Hengshi Honeycomb specialize in tailoring honeycomb panels to precise dimensions, including overall size, specific cell sizes, lengths, materials, and integrated framing systems, ensuring a perfect fit and optimal aerodynamic performance for any unique wind tunnel design or existing facility upgrade. -

What is the typical lifespan of a honeycomb air straightener, and what factors affect it?

The lifespan of a honeycomb in wind tunnel can be very long, often several decades, especially if manufactured from durable materials like stainless steel or appropriately treated aluminum, and operated within specified conditions. Factors affecting lifespan include exposure to corrosive substances, extreme temperature fluctuations, direct mechanical impact, improper handling during installation, and long-term fatigue from vibrations. Regular inspection and proper maintenance can extend its service life. -

How does a honeycomb contribute to energy efficiency in a wind tunnel?

While a wind tunnel honeycomb introduces a small pressure drop, its overall contribution to energy efficiency is significant. By effectively straightening turbulent flow, it reduces energy losses associated with chaotic air movement and allows the main tunnel fan to operate more efficiently, requiring less power to maintain the desired test section velocity. This optimization leads to lower operational costs over the tunnel's lifetime.

Conclusion: Advancing Aerodynamic Research with Superior Honeycomb Technology

The wind tunnel honeycomb stands as a testament to the critical importance of seemingly simple components in complex high-tech systems. Its ability to transform chaotic air into a perfectly laminar flow is not merely a technical detail; it is the fundamental prerequisite for accurate, repeatable, and trustworthy aerodynamic research and development. Without a high-quality air flow straightener, the immense investments in wind tunnel infrastructure and the intricate models tested within them would yield unreliable data, hindering innovation across industries.

As industries demand ever-increasing precision, efficiency, and performance from their products, the role of a superior honeycomb in wind tunnel systems will only continue to grow. Hengshi Honeycomb is proud to be at the forefront of this critical technology, offering the Hengshi Honeycomb Customized Honeycomb Air Straightenerflow Straightener. Our dedication to precision manufacturing, a wide array of material options, unparalleled customization capabilities, and rigorous quality control ensures that our products not only meet but exceed the stringent requirements of modern aerodynamic testing. By choosing Hengshi Honeycomb, you are not just acquiring a component; you are investing in the foundation of accurate research, optimized designs, and ultimately, accelerated innovation.

Our commitment to excellence, backed by ISO 9001 certification and a robust after-sales support system, makes us a trusted partner for research institutions, industrial design centers, and manufacturers worldwide. We empower our clients to push the boundaries of aerodynamic understanding, contributing to breakthroughs in fields from aerospace to renewable energy. Let us partner with you to achieve unparalleled precision in your next aerodynamic endeavor.

References and Further Reading:

- Pope, A., & Harper, J. J. (1966). Low-speed wind tunnel testing. John Wiley & Sons. (A classic textbook discussing wind tunnel design and components including honeycomb).

- Barlow, J. B., Rae, W. H., & Pope, A. (1999). Low-speed wind tunnel testing. John Wiley & Sons. (Updated edition of Pope's work, detailing modern practices).

- AIAA Journal - American Institute of Aeronautics and Astronautics. (Refer to various research papers on wind tunnel flow conditioning). [Example: Search "wind tunnel flow quality" on AIAA website]

- Journal of Fluid Mechanics. (Academic journal, frequently features research on turbulence control and flow conditioning in experimental fluid dynamics). [Example: Search "honeycomb flow straightener" on Journal of Fluid Mechanics archive]

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025