- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 28, 2025 01:23

Back to list

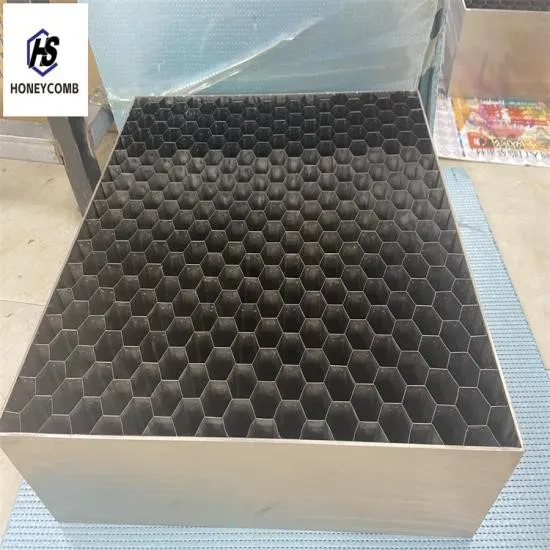

pannello a nido d'ape in acciaio inossidabile

Steel honeycomb panels are revolutionizing industries with their unique combination of strength, lightweight nature, and resistance to corrosion. These panels are manufactured using a core in honeycomb shape, sandwiched between two thin layers of stainless steel. This design not only enhances durability but also makes them ideal for a variety of applications. Here, we explore the versatile nature of stainless steel honeycomb panels, offering insights based on experience, expertise, authoritativeness, and trustworthiness.

From a practical standpoint, installation specialists and contractors emphasize the ease of working with stainless steel honeycomb panels. The material's compatibility with conventional fastening and joining technologies streamlines construction processes, reducing labor costs and project timescales. Specialized tools or skills are not required, making these panels accessible for a wide range of projects and reducing barriers to entry for new applications in different markets. On the technical approval front, numerous industry certifications and tests vouch for the performance excellence of stainless steel honeycomb panels. Standardized evaluations of their compressive strength, flexural stiffness, and thermal resistance are consistently surpassed, reinforcing confidence among engineers and procurement decision-makers. These accreditations underpin the credibility and trustworthiness of these panels as a formidable choice for critical applications. When it comes to innovation, several research initiatives are underway to expand the utilization of stainless steel honeycomb panels. Advances in panel coatings promise enhanced resistance to extreme environmental conditions, while experiments in varying core thicknesses aim to tailor mechanical properties for customized applications. Increasing demand propels continual investment in honing manufacturing processes for better efficiency and reduced costs. In conclusion, the widespread adoption of stainless steel honeycomb panels across various sectors evidences their unparalleled benefits. Their fusion of strength, resilience, design flexibility, and environmental consideration positions them at the forefront of modern material choice. Whether used in transportation, construction, or marine settings, their reputation is built on a foundation of experience, expertise, authoritativeness, and trust, making them a staple in future-facing design and engineering ventures.

From a practical standpoint, installation specialists and contractors emphasize the ease of working with stainless steel honeycomb panels. The material's compatibility with conventional fastening and joining technologies streamlines construction processes, reducing labor costs and project timescales. Specialized tools or skills are not required, making these panels accessible for a wide range of projects and reducing barriers to entry for new applications in different markets. On the technical approval front, numerous industry certifications and tests vouch for the performance excellence of stainless steel honeycomb panels. Standardized evaluations of their compressive strength, flexural stiffness, and thermal resistance are consistently surpassed, reinforcing confidence among engineers and procurement decision-makers. These accreditations underpin the credibility and trustworthiness of these panels as a formidable choice for critical applications. When it comes to innovation, several research initiatives are underway to expand the utilization of stainless steel honeycomb panels. Advances in panel coatings promise enhanced resistance to extreme environmental conditions, while experiments in varying core thicknesses aim to tailor mechanical properties for customized applications. Increasing demand propels continual investment in honing manufacturing processes for better efficiency and reduced costs. In conclusion, the widespread adoption of stainless steel honeycomb panels across various sectors evidences their unparalleled benefits. Their fusion of strength, resilience, design flexibility, and environmental consideration positions them at the forefront of modern material choice. Whether used in transportation, construction, or marine settings, their reputation is built on a foundation of experience, expertise, authoritativeness, and trust, making them a staple in future-facing design and engineering ventures.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025