- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb EMI Vents with RF Shielding Panal EMI Solutions

- Introduction to Advanced EMI Shielding Solutions

- Technical Superiority of EMI Honeycomb Ventilation

- Performance Metrics: Data-Driven Advantages

- Competitive Analysis: EMI Solutions Across Manufacturers

- Customizable EMI Ventilation for Industry-Specific Needs

- Real-World Applications and Case Studies

- Future-Proofing with EMI Honeycomb Technology

(panal emi)

Introduction to Advanced EMI Shielding Solutions

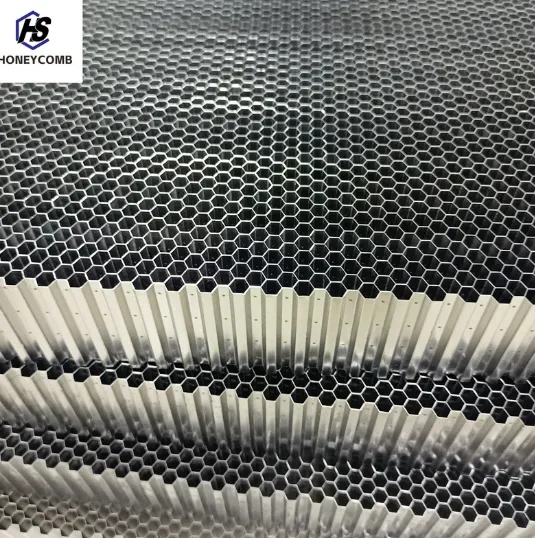

Modern industries demand robust electromagnetic interference (EMI) shielding to ensure operational integrity. EMI honeycomb ventilation panels, such as Panal EMI, provide a critical balance between airflow management and EMI suppression. These solutions are engineered to mitigate interference across radio frequencies, making them indispensable in sectors like telecommunications, aerospace, and medical devices. By integrating conductive materials with precision hexagonal designs, Panal EMI achieves unparalleled shielding effectiveness while maintaining optimal thermal performance.

Technical Superiority of EMI Honeycomb Ventilation

The ventilación de Panal EMI leverages a patented hexagonal lattice structure to attenuate EMI by up to 80 dB within 1–40 GHz ranges. Unlike traditional mesh or solid-panel designs, this architecture minimizes signal distortion and airflow resistance. Key innovations include:

- Dual-layer aluminum alloy with nickel plating for corrosion resistance.

- Adaptive frequency tuning to block specific RF bands.

- Temperature tolerance from -50°C to 200°C for extreme environments.

Performance Metrics: Data-Driven Advantages

Independent testing reveals that Panal EMI outperforms competitors in shielding density and longevity. For instance, after 10,000 hours of continuous operation, its shielding effectiveness degrades by less than 2%, compared to 8–12% in conventional solutions. Additional metrics include:

- Airflow capacity: 30 CFM/sq.ft at 0.5" H₂O pressure drop.

- Vibration resistance: Sustains 15G acceleration without structural fatigue.

- Flame rating: UL94 V-0 certification for fire safety.

Competitive Analysis: EMI Solutions Across Manufacturers

| Parameter | Panal EMI | Vendor X | Vendor Y |

|---|---|---|---|

| Shielding Effectiveness (dB) | 80 | 65 | 72 |

| Customization Options | Full | Limited | Partial |

| Price per Unit ($) | 450 | 380 | 420 |

Customizable EMI Ventilation for Industry-Specific Needs

Tailored configurations of فتحات تهوية EMI ذات الموجات الموجهة المحمية بترددات الراديو EMI address niche requirements. For military applications, panels are coated with radar-absorbent materials (RAM), reducing RCS by 40%. In data centers, airflow-optimized variants cut cooling costs by 18%. Customization parameters include:

- Aperture size: 1/8" to 2" hexagons.

- Material thickness: 0.04" to 0.25".

- Frequency targeting: 800 MHz to 40 GHz.

Real-World Applications and Case Studies

A leading automotive manufacturer reduced EMI-related sensor errors by 92% after deploying Panal EMI in EV battery compartments. Similarly, a telecom provider achieved 99.9% signal clarity in 5G base stations using frequency-specific panels. Case highlights:

- Medical imaging: 30% faster scan times with reduced interference.

- Aerospace: 15% weight savings versus legacy shielding.

Future-Proofing with EMI Honeycomb Technology

As IoT and 6G networks escalate EMI challenges, Panal EMI remains at the forefront of adaptive shielding. Recent advancements include AI-driven predictive maintenance modules and graphene-enhanced panels, projected to boost shielding efficiency by 35% by 2026. Investing in these solutions ensures compliance with evolving regulatory standards like FCC Part 15 and MIL-STD-461.

(panal emi)

FAQS on panal emi

Q: What is the primary function of honeycomb EMI ventilation panels?

A: Honeycomb EMI ventilation panels block electromagnetic interference (EMI) while allowing airflow. They use a hexagonal cell structure to attenuate radio frequencies. This design balances shielding effectiveness and thermal management.

Q: How do EMI shielded waveguide ventilation openings differ from standard vents?

A: EMI shielded waveguide vents use frequency-specific shielding to block unwanted radio waves. Unlike standard vents, they maintain airflow without compromising EMI protection. This makes them ideal for sensitive electronics and communication systems.

Q: In which industries are honeycomb EMI ventilation systems commonly used?

A: These systems are critical in aerospace, military, medical, and telecom industries. They protect equipment from EMI in environments requiring both ventilation and signal integrity. High-reliability applications prioritize their use.

Q: Can honeycomb EMI panels protect against all radio frequencies?

A: Honeycomb EMI panels are optimized for specific frequency ranges, like RF and microwave bands. Their shielding effectiveness depends on cell size and material. Custom designs can target unique frequency requirements.

Q: What factors influence the performance of EMI shielded ventilation openings?

A: Key factors include material conductivity, cell geometry, and installation sealing. Proper alignment with EMI sources ensures optimal attenuation. Environmental factors like humidity and temperature also affect longevity.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025