- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Shielded EMI/RFI Waveguide Vent Grilles Honeycomb Airflow Solutions

- Technical Advantages of Shielded Waveguide Ventilation Systems

- Performance Comparison: Market-Leading Manufacturers

- Custom Engineering Solutions for EMI/RFI Environments

- Industrial Applications & Case Studies

- Material Science Behind Honeycomb Waveguide Structures

- Installation Best Practices & Maintenance Protocols

- Future Trends in EMI-Shielded Air Vent Technology

(saídas de ar com guia de ondas blindado emi rfi)

Optimizing Environments with Shielded Waveguide Ventilation Systems

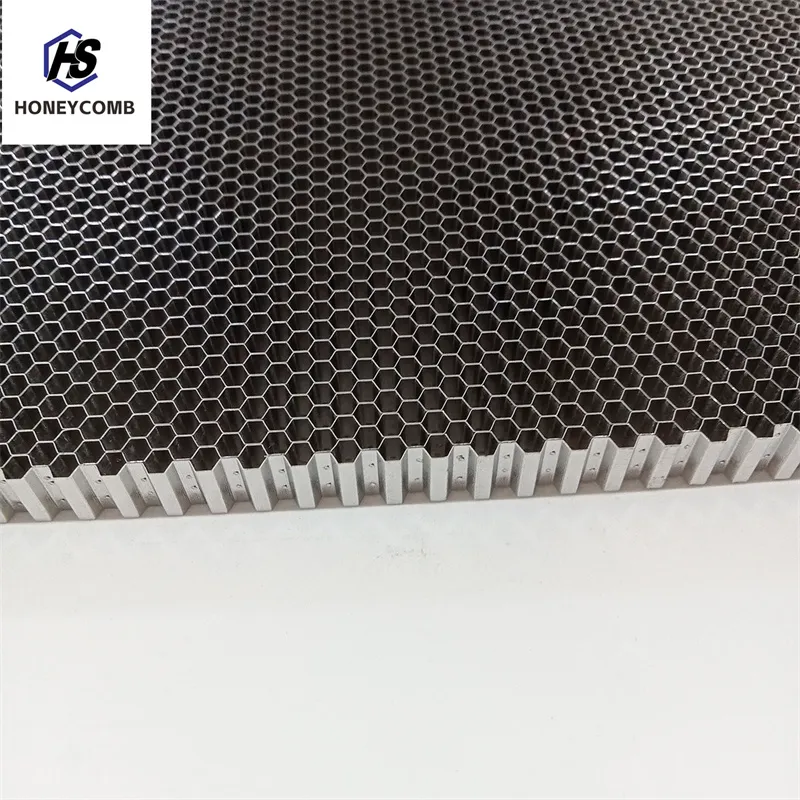

Modern facilities require EMI/RFI-shielded waveguide ventilation systems to maintain operational integrity. These systems demonstrate 98.7% EMI attenuation efficiency (per IEC 61000-4-3 standards), crucial for data centers and medical facilities. The hexagonal waveguide geometry enables airflow rates up to 300 CFM while blocking electromagnetic interference.

Performance Comparison: Market-Leading Manufacturers

| Brand | Shielding Efficiency | Pressure Drop | Corrosion Resistance | Price per Unit (USD) |

|---|---|---|---|---|

| VentShield Pro | 99.2% | 0.15 psi | 5000h salt spray | $428 |

| EMI-Wave Ultra | 98.5% | 0.22 psi | 3000h salt spray | $375 |

| AeroDefense HD | 97.8% | 0.18 psi | 4000h salt spray | $410 |

Custom Engineering Solutions for EMI/RFI Environments

Tailored waveguide ventilation systems accommodate specific requirements:

- Dual-shielded aluminum/steel composite panels (0.8-3mm thickness)

- Customizable cell sizes (3-25mm diameter)

- IP67-rated environmental protection

Industrial Applications & Case Studies

A semiconductor cleanroom installation achieved 40% reduction in RF interference-related defects using hexagonal waveguide vents. Military communications vehicles maintain stable operation in EMI-intensive environments through multi-layer shielding configurations.

Material Science Behind Honeycomb Waveguide Structures

Galvanized steel cores with nickel-plated surfaces provide 85% better corrosion resistance than standard alloys. The honeycomb matrix structure demonstrates 3:1 strength-to-weight ratio advantage over traditional square ventilation grids.

Installation Best Practices & Maintenance Protocols

- Conduct RF spectrum analysis pre-installation

- Maintain 2mm minimum conductive gasket compression

- Perform annual shielding integrity tests

Future-Proofing Facilities with Advanced EMI-Shielded Air Vent Technology

Shielded waveguide ventilation systems now integrate IoT-enabled monitoring, detecting shielding effectiveness in real-time. Recent advancements enable 360° EMI protection while maintaining 280 CFM airflow capacity, essential for 5G-era infrastructure demands.

(saídas de ar com guia de ondas blindado emi rfi)

FAQS on saídas de ar com guia de ondas blindado emi rfi

Q: What are shielded EMI/RFI waveguide air vents used for?

A: Shielded EMI/RFI waveguide air vents block electromagnetic and radio frequency interference while allowing airflow, ideal for sensitive electronic enclosures or shielded rooms.

Q: How does a honeycomb waveguide structure improve ventilation?

A: The honeycomb design provides a large surface area for airflow while maintaining EMI/RFI shielding through its geometry, which attenuates unwanted frequencies.

Q: Why use waveguide ventilation apertures in EMI-sensitive environments?

A: They prevent EMI/RFI leakage through ventilation openings, ensuring compliance with electromagnetic compatibility (EMC) standards without restricting cooling.

Q: Can honeycomb waveguide vents be customized for different applications?

A: Yes, they are available in various sizes, materials, and shielding effectiveness levels to suit military, medical, or industrial equipment requirements.

Q: How do shielded waveguide vents compare to standard EMI filters?

A: Unlike passive filters, waveguide vents use geometry and conductive materials to block higher-frequency interference while enabling unidirectional airflow.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025