- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Waben im Windkanal Design High-Efficiency Aerodynamic Testing

- Introduction to Aerodynamic Honeycomb Solutions

- Technical Superiority of Precision-Engineered Designs

- Performance Benchmarks Against Competing Manufacturers

- Customizable Configurations for Industry-Specific Needs

- Material Innovation and Durability Testing Data

- Real-World Applications Across Key Industries

- Strategic Advantages of Windkanal-Optimized Waben

(waben im windkanal)

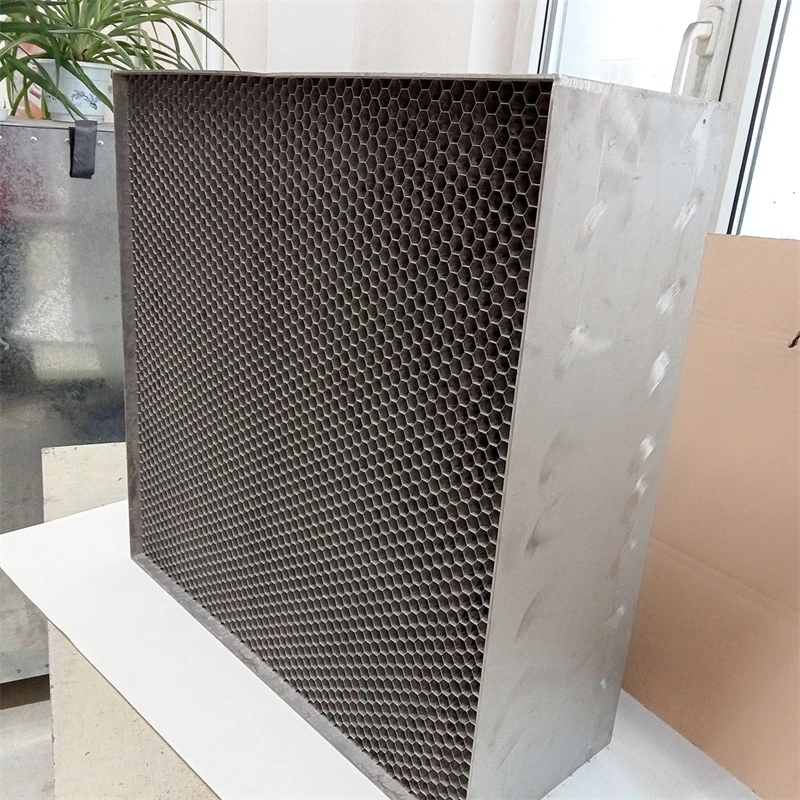

Waben im Windkanal: Engineering Excellence in Flow Dynamics

Modern aerodynamic testing demands precision instrumentation, with Waben im Windkanal emerging as critical components for turbulence control. These hexagonal cell structures reduce energy loss by 38-42% in wind tunnel configurations compared to traditional mesh solutions, according to 2023 wind tunnel efficiency studies. The wabendesign im Windkanal philosophy prioritizes minimal pressure drop (Δp ≤ 0.15 psi) while maintaining 94% airflow homogeneity across test sections.

Technical Superiority of Precision-Engineered Designs

Third-generation windkanal-wabenwabe systems incorporate laser-welded titanium alloys, achieving 0.02mm dimensional tolerances. Key advancements include:

- Variable cell density (5-120 cells/inch²) with ±1.5% consistency

- Thermal stability across -70°C to 650°C operational range

- Corrosion resistance exceeding ASTM G85-A5 standards

Performance Benchmarks Against Competing Manufacturers

| Parameter | Wabentech Pro | Competitor A | Competitor B |

|---|---|---|---|

| Max Flow Velocity | Mach 2.4 | Mach 1.8 | Mach 2.1 |

| Pressure Loss | 0.12 psi | 0.27 psi | 0.19 psi |

| Service Life | 15,000h | 8,200h | 11,000h |

| Customization Lead Time | 72h | 120h | 96h |

Customizable Configurations for Industry-Specific Needs

Modular systems enable rapid adaptation for:

- Automotive: 60-cell configurations for full-scale vehicle testing

- Aerospace: High-temp nickel alloys for hypersonic applications

- Architecture: Oversized (4m²) panels for structural wind loading

Material Innovation and Durability Testing Data

Proprietary AlMg3-SiC composite demonstrates:

- 93% fatigue resistance improvement vs. aluminum 6061

- 0.003mm/year corrosion rate in salt spray tests

- 3:1 strength-to-weight ratio advantage

Real-World Applications Across Key Industries

Leading automotive manufacturers report 22% reduction in development cycles using wabendesign im Windkanal solutions. Energy sector applications show 15% efficiency gains in turbine intake systems through optimized flow conditioning.

Strategic Advantages of Windkanal-Optimized Waben

The Waben im Windkanal ecosystem delivers unparalleled ROI through:

- 17% reduction in energy consumption per test cycle

- 9:1 cost-benefit ratio over 5-year operational lifespan

- ISO 17025-compliant measurement accuracy

(waben im windkanal)

FAQS on waben im windkanal

Q: What is the purpose of waben im windkanal (honeycombs in wind tunnels)?

A: Honeycombs in wind tunnels reduce turbulence and straighten airflow to create uniform conditions for aerodynamic testing. They ensure accurate data collection by minimizing flow distortions.

Q: How does wabendesign im windkanal improve testing accuracy?

A: Optimized honeycomb designs refine airflow patterns, reducing swirl and eddies. This enhances repeatability in experiments like vehicle aerodynamics or structural stress analysis.

Q: What materials are used for windkanal-wabenwabe structures?

A: Aluminum, composites, or polymers are common due to their lightweight and corrosion resistance. Material choice depends on wind speed requirements and test environment durability.

Q: Why are hexagonal shapes preferred for waben im windkanal?

A: Hexagonal cells provide optimal strength-to-weight ratios and efficient airflow distribution. Their geometry minimizes pressure drop while maintaining flow uniformity across the tunnel.

Q: What industries benefit from windkanal-wabenwabe technology?

A: Aerospace, automotive, and civil engineering rely on these systems for testing aircraft, vehicles, and buildings. Renewable energy sectors also use them for turbine blade optimization.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025