Honeycomb Air Flow Straightener - Hengshi|Aerodynamic Testing&EMI Shielding

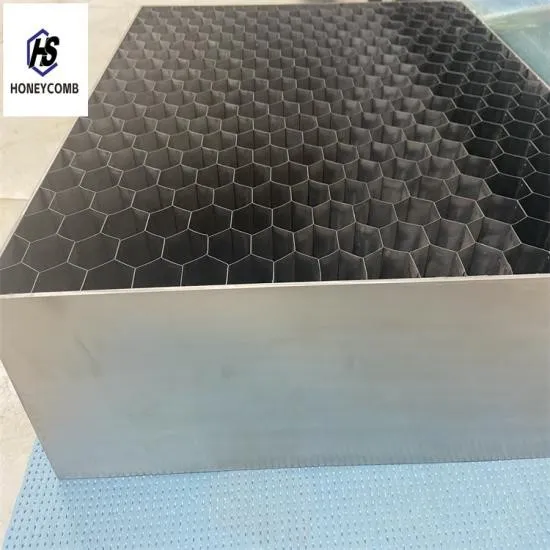

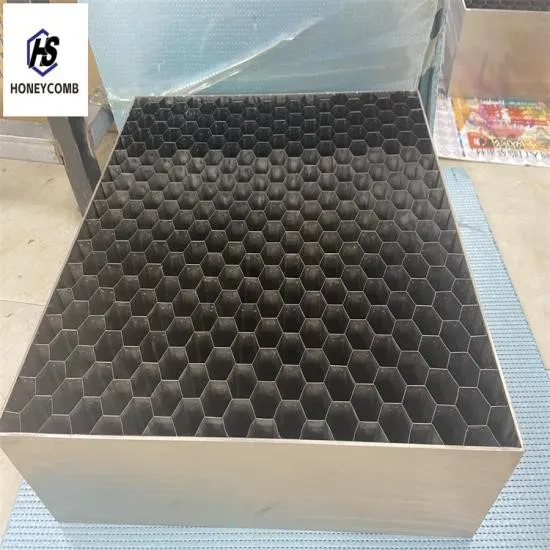

Product Introduction: The Honeycomb Stainless Steel Air Flow Straightener is a critical component in aerodynamic testing, designed to stabilize airflow and enhance measurement accuracy. Its unique structure, inspired by natural honeycomb patterns, ensures laminar flow by reducing turbulence. This product is widely used in industries ranging from aerospace to automotive, offering superior performance in wind tunnel applications. For more details, visit the product page.

Product Function and Advantages

The primary function of the Honeycomb Air Flow Straightener is to transform turbulent airflow into a smooth, laminar flow. This is achieved through its intricate honeycomb structure, which consists of thin cell walls arranged in a hexagonal pattern. The design allows for a maximum open area of 95-99%, minimizing pressure drop while effectively reducing turbulence. This makes it an essential tool in wind tunnels, where precise airflow control is crucial for accurate aerodynamic testing.

The product's advantages are manifold. Its high shielding effectiveness makes it ideal for electromagnetic interference (EMI) shielding, while its corrosion-resistant properties ensure durability in harsh environments. Additionally, the stainless steel construction offers excellent thermal and pressure resistance, making it suitable for high-speed applications such as testing aircraft, missiles, and high-speed trains. The product also excels in sound insulation and ventilation, providing a multifunctional solution for various industrial needs.

Key Benefits:

- Enhanced Measurement Accuracy: Stabilizes airflow to ensure precise data collection in wind tunnels.

- Low Pressure Drop: Maintains efficient airflow with minimal resistance.

- Durability: Resistant to corrosion, heat, and pressure, ensuring long-term reliability.

- Versatility: Suitable for applications in aerospace, automotive, marine, and more.

Technical Specifications

The Honeycomb Stainless Steel Air Flow Straightener is available in a wide range of materials, sizes, and configurations to meet diverse industrial requirements. Below is a detailed specification table:

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper, etc. |

|---|---|

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, 6.0, 8, 10, 12, 20, 30 mm (customizable) |

| Thickness | Customized |

| Shape | As required (e.g., rectangular, circular) |

| Surface Treatment | Painting, white oxygen, Electroless Nickel plating, electrophoresis, powder coating, brush (customizable) |

| Package | Wooden cases or as required |

| Certifications | ISO9001, RoHS |

| Welding Technology | Spot welding, vacuum brazing |

| Function | EMI Shielding, Air Ventilation, Cooling, Corrosion Resistance |

| Applications | EMI shielding vent, flow straightener, railways, marine, aviation/aerospace, wind energy, defense, gas seals, communications, medical, and other industries. |

Applications in Aerodynamic Testing

Wind Tunnel Integration: The Honeycomb Air Flow Straightener is a staple in wind tunnel systems, where it ensures consistent airflow for accurate aerodynamic analysis. By eliminating turbulence, it allows engineers to study the effects of air resistance, heat, and pressure on objects such as aircraft, cars, and buildings. This is particularly critical in the development of high-speed vehicles, where even minor airflow irregularities can impact performance.

Wind tunnels are essential tools for testing aerodynamic properties. They simulate real-world conditions by generating controlled airflow, enabling researchers to evaluate designs before physical prototypes are built. The Honeycomb Air Flow Straightener plays a pivotal role in this process, ensuring that the airflow within the tunnel is as close to natural conditions as possible. This is especially important for applications like crash testing in automotive engineering or flight simulations in aerospace.

Other key applications include:

- Automotive Industry: Testing vehicle aerodynamics to improve fuel efficiency and stability.

- Aerospace: Evaluating the performance of aircraft and missiles under various conditions.

- Marine Engineering: Assessing the hydrodynamic properties of ships and submarines.

- Renewable Energy: Optimizing wind turbine blade designs for maximum efficiency.

- Defense: Testing the aerodynamic and structural integrity of military equipment.

Company Background: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

About Hengshi: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. is a leading manufacturer specializing in high-quality shielding products, including ventilation panels, steel honeycomb cores, and honeycomb air flow straighteners. With a focus on innovation and precision, the company serves a global clientele across multiple industries. Their commitment to quality is reflected in their ISO9001 and RoHS certifications, ensuring compliance with international standards.

Founded with a vision to provide reliable and durable solutions for industrial challenges, Hengshi has established itself as a trusted name in the field of aerodynamic testing and EMI shielding. Their expertise in custom manufacturing allows them to tailor products to specific client requirements, whether it's a small-scale project or large-scale industrial applications. The company's state-of-the-art facilities and rigorous quality control processes ensure that every product meets the highest standards of performance and safety.

Key Highlights:

- Expertise: Over a decade of experience in manufacturing precision components.

- Customization: Ability to produce products in various materials, sizes, and configurations.

- Global Reach: Serving clients in aerospace, automotive, defense, and other industries worldwide.

- Commitment to Quality: Adherence to ISO9001 and RoHS standards for reliability and sustainability.

Conclusion

The Honeycomb Stainless Steel Air Flow Straightener is a testament to the power of engineering innovation. Its ability to stabilize airflow, reduce turbulence, and enhance measurement accuracy makes it indispensable in aerodynamic testing. Whether used in wind tunnels for aerospace research or in industrial applications requiring EMI shielding, this product exemplifies the balance between functionality and durability.

For those seeking a reliable partner in precision manufacturing, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. offers a comprehensive range of solutions tailored to meet the demands of modern industries. By combining advanced technology with a commitment to quality, the company continues to drive progress in fields that rely on precise airflow control and robust material performance.

References

1. National Institute of Standards and Technology (NIST) - While direct access to NIST resources was unavailable, the organization's role in establishing standards for measurement and testing underscores the importance of precision in industrial applications. For more information on NIST's contributions to technology and innovation, visit their official website.

2. Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. - Company Website.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025