- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Hunajakennotiivisteet ovat kestäviä ja kestävät äärimmäisiä lämpötiloja

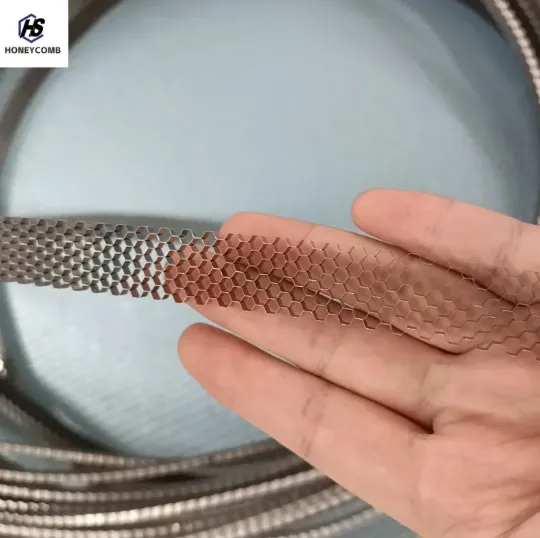

Nykyaikaisen materiaalitieteen ja tekniikan alalla hunajakennorakenteita käytetään laajalti eri teollisuudenaloilla, kuten ilmailu-, auto- ja rakennusteollisuudessa erinomaisten mekaanisten ominaisuuksiensa ja keveysominaisuuksiensa ansiosta. Heidän joukossaan hunajakennotiivisteet, yleisenä hunajakennorakenteena, ovat erityisen tärkeitä niiden kestävyyden ja äärimmäisiin lämpötiloihin sopeutuvuuden vuoksi. Tämän artikkelin tarkoituksena on tutkia kennotiivisteiden kestävyyttä ja niiden suorituskykyä äärimmäisissä lämpötiloissa.

Kennotiivisteiden kestävyys näkyy pääasiassa niiden rakenteellisessa lujuudessa ja iskunkestävyydessä

Hunajakennorakenne ottaa sisäisen onton muodon, jonka ansiosta se säilyttää kevyen painon samalla kun sillä on hyvät puristus-, taivutus- ja leikkauskestävyysominaisuudet. Tämä ominaisuus mahdollistaa kennonauhat kestää suuria kuormia ilman, että se helposti vääntyy tai vaurioituu. Lisäksi pinta hunajakennotiivisteet on yleensä käsitelty erikoiskäsittelyillä niiden korroosionkestävyyden ja kulutuskestävyyden parantamiseksi, mikä pidentää niiden käyttöikää. Käytännön sovelluksissa kokeellisesti validoidut kennotiivisteet voivat säilyttää suorituskyvyn vakaumuksensa pitkäaikaisessa käytössä, mikä tekee niistä ihanteellisia rakennemateriaaleja.

Hunajakennotiivisteiden suorituskykyyn äärimmäisissä lämpötiloissa kannattaa myös kiinnittää huomiota

Korkeat ja matalat lämpötilat vaikuttavat usein merkittävästi materiaalien fysikaalisiin ominaisuuksiin. Tutkimukset ovat osoittaneet, että kennotiivisteet voivat kohdata ongelmia, kuten lämpölaajeneminen, heikentynyt lujuus ja materiaalin muodonmuutos korkeissa lämpötiloissa. Matalissa lämpötiloissa materiaalien sitkeys voi heikentyä, mikä lisää haurautta. Hunajakennotiivisteiden käytettävyyden varmistamiseksi äärimmäisissä lämpötiloissa tutkijat valitsevat siksi tyypillisesti erikoisraaka-aineita, kuten korkeita ja matalia lämpötiloja kestäviä komposiittimateriaaleja, jotka täyttävät erilaiset sovellusvaatimukset.

Lämpötilan muutoksilla on myös merkittävä vaikutus liimamateriaalien suorituskykyyn, ja kennotiivisteet liitetään usein toisiinsa sidostekniikalla yksikkösoluiksi.

Ympäristössä, jossa vuorottelevat korkeat ja matalat lämpötilat, liiman tarttumiskyky voi heikentyä, mikä vaikuttaa koko rakenteen vakauteen. Siksi sopivien liimausmateriaalien ja -tekniikoiden valinta on myös keskeistä kestävyyden parantamiseksi Hunajakennotiiviste kaasuturbiini äärimmäisissä lämpötiloissa.

Yhteenvetona, sinetöityjä hunajakennoja ovat osoittaneet laajat sovellusmahdollisuudet nykyaikaisessa suunnittelussa erinomaisen kestävyyden ja kykynsä mukautua äärimmäisiin lämpötiloihin ansiosta. Huolimatta haasteista äärimmäisissä korkeissa ja matalissa lämpötiloissa, kennotiivisteet voivat silti säilyttää suorituskykynsä erilaisissa olosuhteissa optimoimalla materiaalin valinnan ja rakennesuunnittelun. Tämä ei ainoastaan osoita solurakenteiden tutkimus- ja sovelluspotentiaalia, vaan tarjoaa myös tärkeitä suuntaviivoja tulevalle teknologiselle kehitykselle.

Tuoteluokat

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsUutisetJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionUutisetJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsUutisetJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionUutisetJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsUutisetJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsUutisetJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlUutisetJul.11,2025