- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

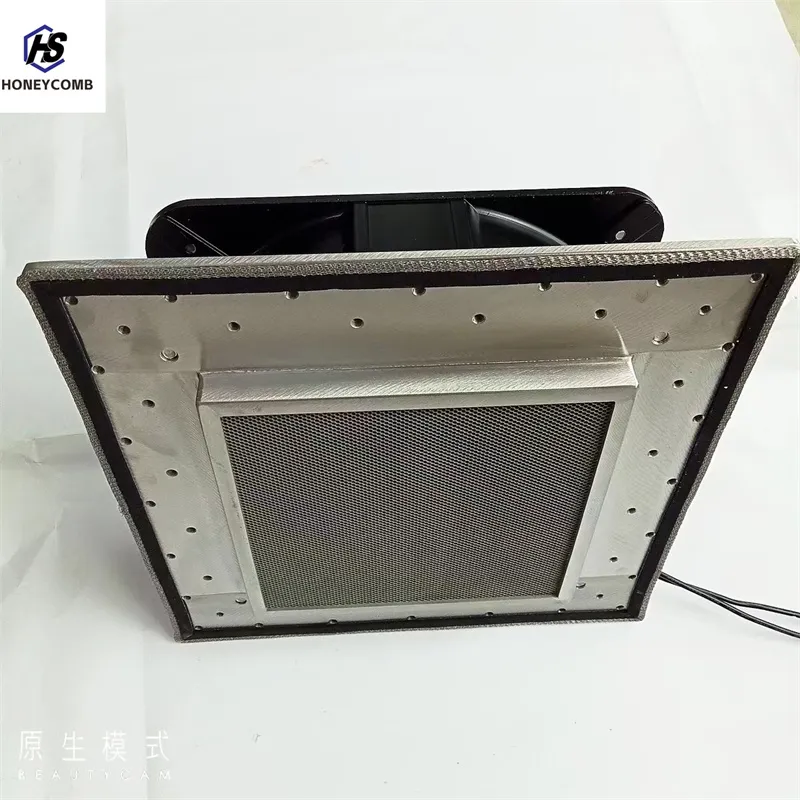

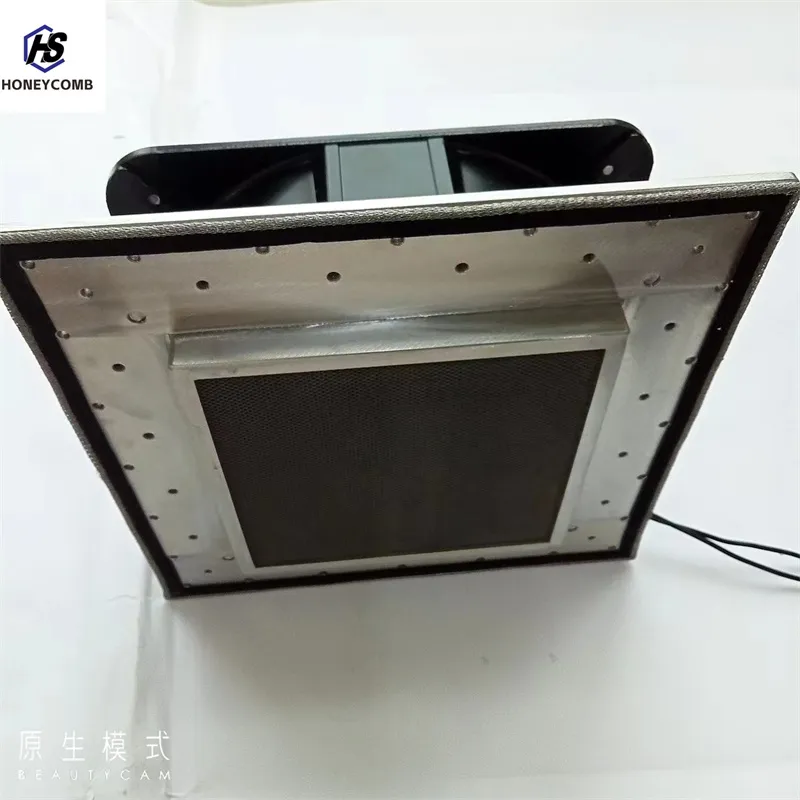

Stainless Steel EMI Honeycomb Vent Panels for Shielded Tents | High Shielding Effectiveness

Industry Overview and Trends

The demand for electromagnetic interference (EMI) shielding solutions has surged exponentially in military, medical, and telecom industries. As digital systems become more pervasive and operate at higher frequencies, the need for effective EMI shielding in temporary structures like shielded tents has become critical. Stainless Steel EMI Honeycomb Vent Panels for Shielded Tent represent the cutting-edge solution that combines essential ventilation with uncompromised electromagnetic shielding.

Traditional EMI shielding solutions presented significant limitations in mobile and temporary installations. Solid metal panels blocked interference but prevented necessary airflow, creating operational challenges. Mesh solutions allowed ventilation but provided insufficient protection against higher-frequency interference. Stainless Steel EMI Honeycomb Vent Panels overcome these limitations by leveraging the physics of hexagonal structures that attenuate electromagnetic waves while maintaining excellent airflow.

Product Overview

Stainless Steel EMI Honeycomb Vent Panels for Shielded Tent manufactured by Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. represent the pinnacle of EMI shielding technology. These panels feature precision-engineered hexagonal stainless steel cells that create a Faraday cage effect, blocking electromagnetic interference while enabling essential airflow for personnel comfort and equipment cooling.

Hengshi Honeycomb offers customizable metallic EMI/RF shielded honeycomb ventilation panels with core sizes ranging from 0.8mm up to 30mm. Our proprietary manufacturing capabilities include independently developed honeycomb stamping equipment and laser welding systems. Our mastery of high-temperature vacuum brazing technology enables us to meet diverse customer requirements. Both welding techniques comply with ROHS environmental standards, guaranteeing both performance and sustainability.

✓ Advanced Manufacturing

Independently developed stamping and laser welding equipment ensures precision engineering for every honeycomb cell structure.

✓ Dual Welding Technologies

Mastery of both laser welding and vacuum brazing techniques provides solutions for diverse application requirements.

✓ ROHS Compliance

All manufacturing processes adhere to stringent environmental standards with zero hazardous substances.

Technical Specifications

| Parameter | Specification | Details |

|---|---|---|

| Material | Stainless Steel (Grades 304, 316) | Corrosion resistance: Salt spray test 500+ hours |

| Cell Size | 0.8mm - 30mm | Optimized for specific frequency requirements |

| Thickness | 6mm - 100mm | Customizable based on shielding requirements |

| Shielding Effectiveness | Up to 120 dB | Measured from 10 MHz to 40 GHz |

| Airflow Capacity | 40-85% open area | Optimized ventilation performance |

| Temperature Range | -40°C to 200°C | Suitable for extreme environments |

| Vibration Resistance | MIL-STD-810G | Military-grade durability |

Performance Analysis

Application Gallery

Technical Expertise FAQ

Industry Recognition

Independent testing of Hengshi's honeycomb technology has demonstrated exceptional performance metrics that lead the industry. Military evaluations at the NATO Communications and Information Agency validated attenuation exceeding 120 dB at critical communication frequencies. Telecommunications industry testing confirmed consistent performance across the 5G spectrum.

Recent academic research published in the IEEE Transactions on Electromagnetic Compatibility has established new theoretical models confirming the superior attenuation properties of hexagonal structures compared to square or circular cell geometries. The mathematical analysis demonstrates a 18.6% improvement in cutoff frequency performance with hexagonally structured Stainless Steel EMI Honeycomb Vent Panels.

Contact Hengshi Precision

Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. remains at the forefront of EMI shielding technology. Our commitment to precision engineering and continuous innovation drives improvements in Stainless Steel EMI Honeycomb Vent Panels for Shielded Tent year after year. Visit our website to learn how our solutions can protect your critical communications and electronic systems in the most demanding environments.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025