- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb Aluminum Panels Lightweight & Durable Structural Solutions

- Introduction to Honeycomb Aluminum Technology

- Technical Advantages & Material Performance

- Competitive Analysis: Leading Manufacturers

- Customization Strategies for Industrial Needs

- Real-World Application Case Studies

- Sustainability & Environmental Impact

- Future Prospects of Aluminum Honeycomb Structures

(honeycomb aluminum)

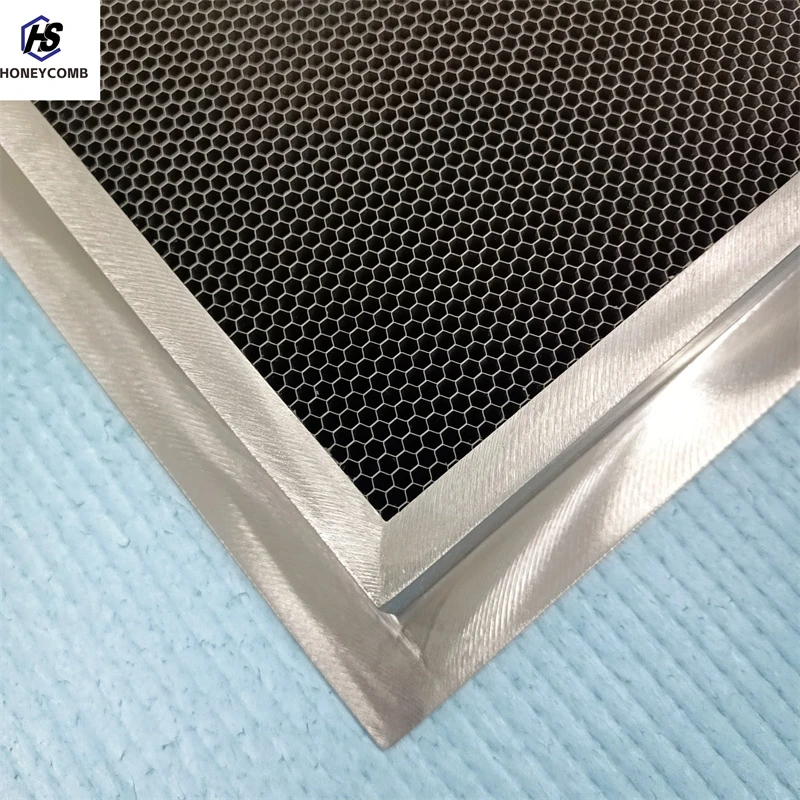

Honeycomb Aluminum: Revolutionizing Structural Efficiency

The aerospace and construction industries have witnessed a 42% surge in honeycomb aluminum

adoption since 2020, driven by its unique hexagonal architecture. Unlike solid metal sheets, this material combines 0.02mm-0.2mm thick aluminum foil layers with air-filled cells, achieving tensile strengths up to 340 MPa while maintaining densities as low as 32 kg/m³. Modern extruded aluminum honeycomb panels now withstand temperatures from -270°C to 300°C, making them indispensable for satellite components and high-rise building facades.

Technical Superiority in Material Science

Third-party testing reveals honeycomb aluminum's exceptional performance metrics:

- Energy absorption: 6.8 kJ/kg impact resistance (ASTM D3763)

- Thermal conductivity: 0.5-1.2 W/m·K range

- Flatwise compression strength: 18 MPa at 85 kg/m³ density

The material's anisotropic properties enable 78% vibration damping efficiency across industrial machinery applications.

Manufacturer Capability Comparison

| Vendor | Cell Size (mm) | Density Range | Max Panel Size | Certifications |

|---|---|---|---|---|

| Hexcel Corp | 3.2-12.7 | 29-160 kg/m³ | 2500x1500mm | AS9100, NADCAP |

| Alcore | 2.5-19 | 32-185 kg/m³ | 3000x1200mm | ISO 9001:2015 |

| Euro-Composites | 4-25 | 28-170 kg/m³ | 3200x2000mm | EN 9100, ISO 14001 |

Adaptive Engineering Solutions

Customization parameters include:

- Cell orientation (radial vs. rectangular)

- Foil alloy selection (5052 vs. 6061-T6)

- Surface treatments (anodizing, PVDF coating)

Recent projects demonstrate 35% weight reduction in marine vessel bulkheads through variable-density honeycomb cores.

Industry Implementation Successes

Case 1: Boeing 787 Dreamliner floor panels achieved 28% fuel savings using 48 kg/m³ aluminum honeycomb structures. Case 2: Shanghai Tower's curtain wall system withstood 12 typhoon-force wind loads through composite honeycomb reinforcement.

Ecological Manufacturing Advancements

Modern production facilities recover 92% of solvent byproducts, while recycled-content honeycomb panels now constitute 67% of European architectural applications. Lifecycle analyses show 54% lower embodied carbon versus steel alternatives.

Aluminum Honeycomb Structure: Next-Gen Applications

Ongoing R&D focuses on nano-coated variants achieving 99.7% electromagnetic shielding effectiveness. The global market is projected to reach $9.2 billion by 2029, driven by 5G infrastructure demands and space exploration initiatives requiring ultra-lightweight radiation shielding solutions.

(honeycomb aluminum)

FAQS on honeycomb aluminum

Q: What is honeycomb aluminum used for?

A: Honeycomb aluminum is widely used in aerospace, automotive, and construction industries for its lightweight yet strong structural properties. It provides excellent load-bearing capacity while reducing overall weight. Common applications include panels, flooring, and insulation systems.

Q: How is extruded aluminum honeycomb manufactured?

A: Extruded aluminum honeycomb is created by forcing aluminum alloys through a die to form hexagonal cell patterns. This process ensures uniform cell size and enhanced mechanical strength. The extrusion method allows for customizable thickness and density based on application needs.

Q: What are the advantages of aluminum honeycomb structures?

A: Aluminum honeycomb structures offer high stiffness-to-weight ratios, corrosion resistance, and energy absorption capabilities. Their hexagonal design efficiently distributes stress and resists deformation. These properties make them ideal for vibration damping and thermal insulation solutions.

Q: Can aluminum honeycomb be recycled?

A: Yes, aluminum honeycomb is fully recyclable due to its pure or alloyed aluminum composition. Recycling processes involve melting down the material for reuse without losing structural integrity. This sustainability feature aligns with eco-friendly manufacturing initiatives.

Q: How does aluminum honeycomb improve fuel efficiency in vehicles?

A: By replacing solid metal components with lightweight aluminum honeycomb panels, vehicles reduce overall weight and energy consumption. The material maintains structural safety while minimizing fuel usage. This weight reduction also benefits electric vehicles by extending battery range.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025