- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 00:50

Back to list

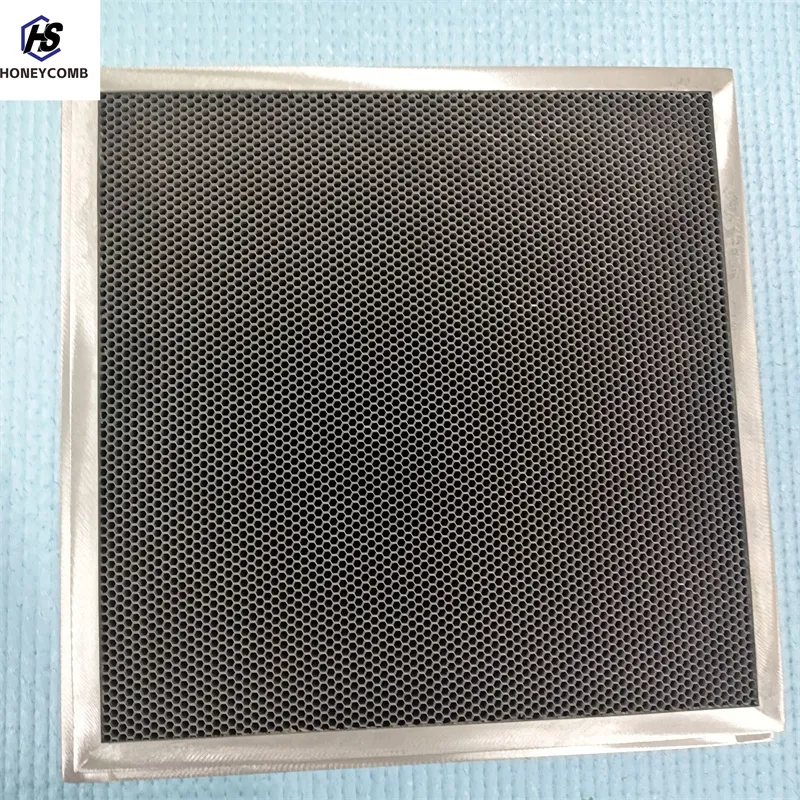

قرص عسل من الألومنيوم

Aluminum honeycomb panels a product often overlooked yet critically acclaimed in industries requiring strength, versatility, and innovation. Through decades of engineering advancements, these panels have risen as a paradigm in materials science, offering unrivaled benefits that eclipse traditional options.

Trust in a material is earned through rigorous testing and proven performance. The intrinsic reliability of aluminum honeycomb panels is validated through international standards and certifications. Engineers value these endorsements, knowing that they are working with a material that consistently exceeds industry thresholds. Aluminum’s corrosion-resistant properties further enhance trustworthiness, providing peace of mind regarding longevity and maintenance. With minimal upkeep, structures incorporating aluminum honeycomb panels promise sustained performance, a cost-effective solution in the long term. This trust is mirrored in customer satisfaction and repeat procurement from reputable firms. Expertise in deploying aluminum honeycomb panels can lead to innovations across sectors. With state-of-the-art machinery and cutting-edge techniques, manufacturers are revolutionizing methods to incorporate these panels in even the most challenging applications. Automotive industries utilize them for chassis components, reducing vehicle weight and consequently boosting energy efficiency while maintaining safety standards. The authenticity of the benefits discussed come not just from theoretical knowledge but from hands-on experience and extensive collaboration with professionals across industries. Attending various international trade shows has fortified my perspective on the detached awe the global community holds for aluminum honeycomb technology. In conclusion, aluminum honeycomb panels embody a confluence of engineering prowess and environmental stewardship. Professionals across fields trust these panels to deliver solutions that are not only structurally sound but also aesthetic and sustainable. Emphasizing a commitment to quality and resilience, these panels stand as a testament to human ingenuity in materials design, continuously shaping the future of construction, aviation, and beyond.

Trust in a material is earned through rigorous testing and proven performance. The intrinsic reliability of aluminum honeycomb panels is validated through international standards and certifications. Engineers value these endorsements, knowing that they are working with a material that consistently exceeds industry thresholds. Aluminum’s corrosion-resistant properties further enhance trustworthiness, providing peace of mind regarding longevity and maintenance. With minimal upkeep, structures incorporating aluminum honeycomb panels promise sustained performance, a cost-effective solution in the long term. This trust is mirrored in customer satisfaction and repeat procurement from reputable firms. Expertise in deploying aluminum honeycomb panels can lead to innovations across sectors. With state-of-the-art machinery and cutting-edge techniques, manufacturers are revolutionizing methods to incorporate these panels in even the most challenging applications. Automotive industries utilize them for chassis components, reducing vehicle weight and consequently boosting energy efficiency while maintaining safety standards. The authenticity of the benefits discussed come not just from theoretical knowledge but from hands-on experience and extensive collaboration with professionals across industries. Attending various international trade shows has fortified my perspective on the detached awe the global community holds for aluminum honeycomb technology. In conclusion, aluminum honeycomb panels embody a confluence of engineering prowess and environmental stewardship. Professionals across fields trust these panels to deliver solutions that are not only structurally sound but also aesthetic and sustainable. Emphasizing a commitment to quality and resilience, these panels stand as a testament to human ingenuity in materials design, continuously shaping the future of construction, aviation, and beyond.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025