- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Versatile Applications of Honeycomb Structures in Modern Industries

The rise of ragamar saƙar zuma in engineering and manufacturing reflects a broader shift toward materials that offer both structural efficiency and environmental resilience. With its open hexagonal geometry, this mesh delivers a remarkable combination of strength and lightweight flexibility. Made from stainless steel, it is particularly effective in applications requiring filtration, reinforcement, or heat dissipation.

Industries such as aerospace, automotive, and petrochemicals rely on ragamar saƙar zuma for its ability to maintain mechanical integrity under thermal stress or corrosive exposure. In heat exchangers, catalytic converters, or high-temperature shields, the mesh’s open structure promotes airflow while still providing reinforcement. Its adaptability allows it to be cut, welded, or laminated into complex shapes, making it a key material in the ongoing evolution of high-performance designs.

Honeycomb Sandwich Panel for Multi-Layer Structural Stability

The sandwich panel na saƙar zuma stands out as a multifunctional engineering product that blends strength, insulation, and weight reduction. Composed of a lightweight core bonded between two rigid outer skins, this three-layer panel offers outstanding bending resistance and load-bearing capabilities. The honeycomb structure ensures that mechanical forces are evenly distributed, reducing localized stress while optimizing material usage.

Industries ranging from aerospace to architecture deploy sandwich panel na saƙar zuma systems in floor panels, bulkheads, and façade claddings. These panels can be manufactured from stainless steel, aluminum, or composite materials depending on application needs. Their durability and form stability under thermal and mechanical loads make them indispensable in modular buildings, aircraft interiors, and cleanrooms. Moreover, their ability to accommodate acoustic or fire-resistant layers further enhances their appeal in complex projects.

A Lightweight, Durable Alternative: Honeycomb Aluminum Panel

The saƙar zuma aluminum panel has become a material of choice in modern construction and transportation projects due to its exceptional balance between weight and strength. Made by bonding aluminum skins to an aluminum honeycomb core, this panel provides superior stiffness while remaining extremely light. Its corrosion resistance and surface finish quality make it ideal for decorative applications without compromising on performance.

Honeycomb aluminum panel products are frequently used in curtain walls, ceilings, signage, and marine panels. Architects and engineers appreciate the flexibility in thickness, panel size, and coating options. Moreover, its recyclable nature aligns with growing global efforts toward sustainable building practices. Whether used in skyscrapers or yacht interiors, this panel ensures that design elegance meets industrial rigor.

Stainless Steel Honeycomb Cookware: Durable Meets Functional

In the culinary world, bakin karfe girkin zumar zuma represents a significant innovation that brings professional-grade performance to everyday kitchens. These pans and pots are designed with a unique honeycomb-patterned cooking surface, which integrates raised stainless steel ridges with a nonstick layer beneath. This hybrid surface allows for efficient heat conduction, scratch resistance, and even cooking.

Consumers and chefs alike choose bakin karfe girkin zumar zuma for its durability, ease of cleaning, and ability to handle high-heat cooking without degrading. Unlike traditional nonstick pans, which often wear down quickly, the honeycomb surface protects the nonstick coating and extends product life. Whether searing steaks or simmering sauces, this cookware delivers precision, safety, and consistency in performance.

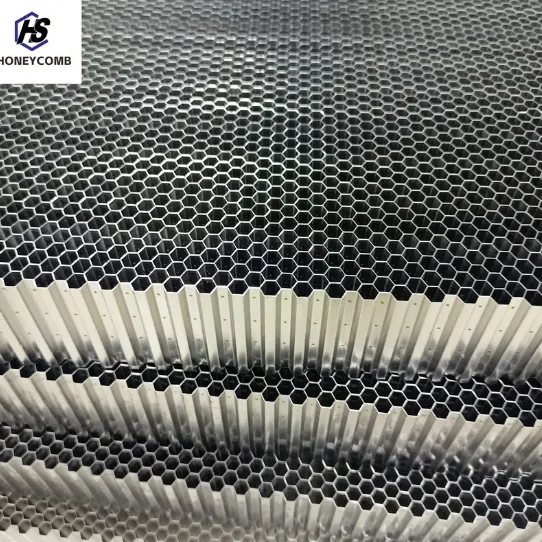

Honeycomb Flow Straightener Enhancing Fluid Dynamics Control

Precision in fluid movement is critical across a wide range of applications, from aerospace wind tunnels to automotive intake systems. The madaidaicin saƙar zuma is an engineering solution designed to align turbulent or swirling flow into a consistent, laminar pattern. Constructed with thin-walled honeycomb cells, often made from aluminum or stainless steel, these devices ensure uniform velocity profiles for accurate measurements and improved system efficiency.

By reducing turbulence and vortex distortion, the madaidaicin saƙar zuma enhances the accuracy of fluid dynamic experiments and optimizes performance in combustion engines and ventilation ducts. These structures are also valuable in air quality monitoring, exhaust systems, and laboratory testing environments where precise airflow is essential. Their low-pressure drop and customizable dimensions make them adaptable to almost any engineering setup involving controlled fluid or air passage.

honeycomb sandwich panel FAQs

What are the advantages of using a steel honeycomb mesh in filtration and structural support?

Steel honeycomb mesh offers high mechanical strength, thermal resistance, and corrosion protection. Its open-cell structure enables efficient air or fluid passage while providing structural reinforcement. This makes it ideal for filters, thermal shields, and mechanical enclosures across various industries.

How is a honeycomb sandwich panel customized for different industries?

The sandwich panel na saƙar zuma can be tailored using different core materials, skin thicknesses, and surface finishes. Whether it's for aircraft cabin floors, architectural walls, or marine partitions, panels are configured to meet specific strength, weight, fire safety, and acoustic requirements.

Where is honeycomb aluminum panel most effectively used in construction?

Honeycomb aluminum panel is widely used in building façades, interior partitions, ceilings, and marine construction. It provides strength, corrosion resistance, and aesthetic appeal while remaining lightweight, making it perfect for structures requiring both durability and visual elegance.

Why is stainless steel honeycomb cookware preferred over traditional pans?

Stainless steel honeycomb cookware combines the robustness of stainless steel with the convenience of nonstick cooking. Its hybrid surface ensures scratch resistance and long-lasting nonstick performance, making it more durable and reliable than traditional nonstick pans under high-temperature cooking.

How does a honeycomb flow straightener improve performance in engineering systems?

The madaidaicin saƙar zuma aligns turbulent fluid or airflows into a smooth, laminar flow. This results in more accurate readings in instrumentation, better combustion efficiency, and optimized airflow in ducts or wind tunnels. Its precision-engineered design supports applications requiring consistent fluid dynamics.

Rukunin samfuran

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsLabaraiJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionLabaraiJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsLabaraiJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionLabaraiJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsLabaraiJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsLabaraiJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlLabaraiJul.11,2025