- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 10:36

Back to list

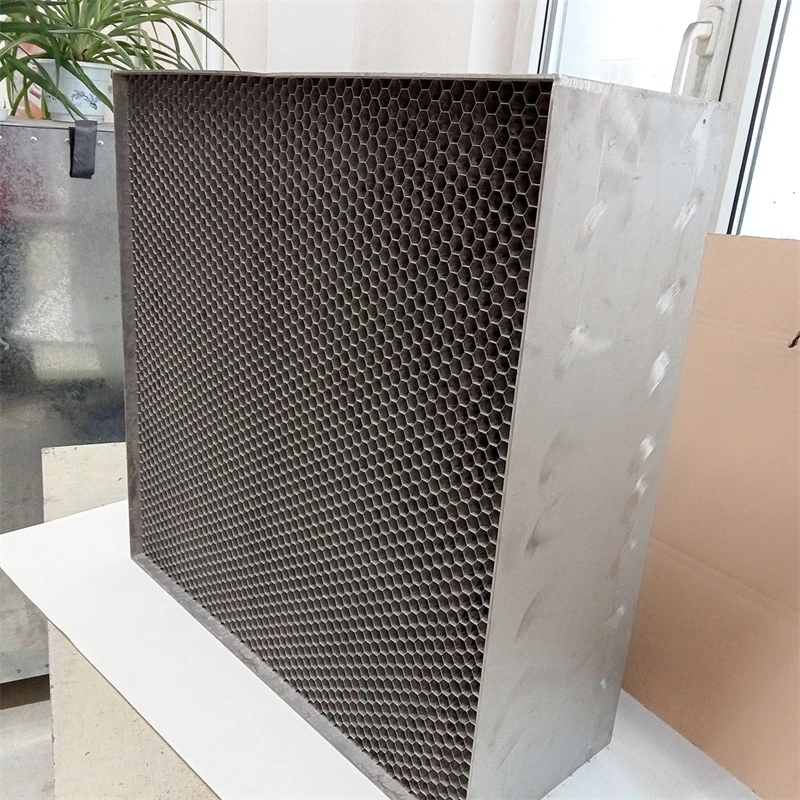

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

Unlocking the Potential of Cell Aluminium Honeycomb

Authoritativeness of cell aluminum honeycomb is well established in industries that demand excellence and reliability. Recognized by top engineers and material scientists, these panels have been subjected to countless studies and practical tests, proving their exceptional performance in load-bearing capacity and impact resistance. Leading institutions have documented their efficacy, solidifying the reputation of aluminum honeycomb panels as a go-to material when seeking an optimal balance between weight, strength, and cost-efficiency. Trustworthiness is woven into the fabric of these panels, a quality that stems from the transparency of the manufacturing process and the predictability of performance. Clients and end-users can rely on the extensive data and field tests that back the application of these materials. Additionally, advancements in surface treatments and bonding techniques further enhance their corrosion resistance, extending their lifespan even in the most challenging environments. This dependability is why architects and engineers consistently advocate for their use in critical infrastructure projects. In conclusion, cell aluminum honeycomb panels are not just about lightweight construction; they are about smart engineering and sustainable design. Whether utilized in the sleek lines of modern architectural façades or in the fuselage of a cutting-edge aircraft, their untapped potential holds promise for innovative applications across multiple domains. By aligning real-world experience, technical expertise, and a robust framework of trust, aluminum honeycomb structures are poised to redefine the benchmarks of performance and sustainability in the material world.

Authoritativeness of cell aluminum honeycomb is well established in industries that demand excellence and reliability. Recognized by top engineers and material scientists, these panels have been subjected to countless studies and practical tests, proving their exceptional performance in load-bearing capacity and impact resistance. Leading institutions have documented their efficacy, solidifying the reputation of aluminum honeycomb panels as a go-to material when seeking an optimal balance between weight, strength, and cost-efficiency. Trustworthiness is woven into the fabric of these panels, a quality that stems from the transparency of the manufacturing process and the predictability of performance. Clients and end-users can rely on the extensive data and field tests that back the application of these materials. Additionally, advancements in surface treatments and bonding techniques further enhance their corrosion resistance, extending their lifespan even in the most challenging environments. This dependability is why architects and engineers consistently advocate for their use in critical infrastructure projects. In conclusion, cell aluminum honeycomb panels are not just about lightweight construction; they are about smart engineering and sustainable design. Whether utilized in the sleek lines of modern architectural façades or in the fuselage of a cutting-edge aircraft, their untapped potential holds promise for innovative applications across multiple domains. By aligning real-world experience, technical expertise, and a robust framework of trust, aluminum honeycomb structures are poised to redefine the benchmarks of performance and sustainability in the material world.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025