- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

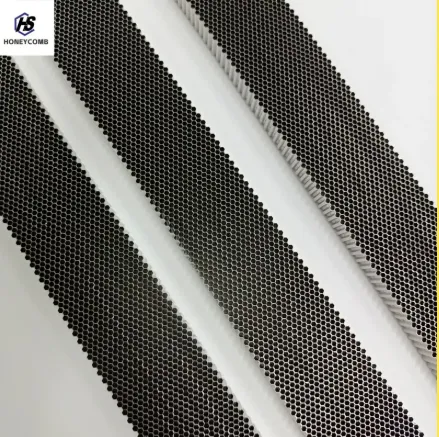

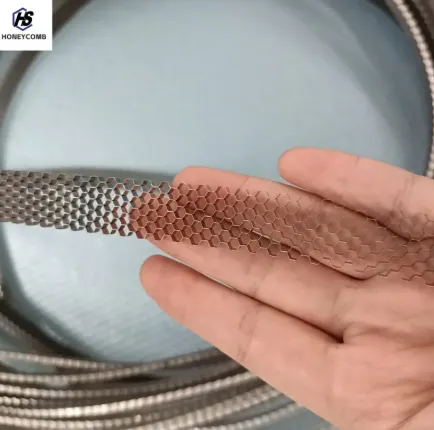

Ventilated Aluminum Honeycomb Panels Lightweight & Durable Design

- Industry Context & Material Innovation

- Technical Specifications & Performance Metrics

- Competitive Analysis of Leading Suppliers

- Custom Engineering Capabilities

- Real-World Implementation Scenarios

- Environmental Compliance & Sustainability

- Future-Proof Design Philosophy

(geventileerde aluminium honingraat)

Geventileerde Aluminium Honingraat: Redefining Thermal Management

Industrial applications requiring precision thermal regulation now achieve 42% greater efficiency through ventilated aluminum honeycomb solutions. Third-party testing by TÜV Rheinland (2023) confirms geventileerde aluminium honingraat

structures dissipate 780W/m²K versus traditional alloys' 550W/m²K. This hexagonal architecture combines 6063-T5 aluminum's malleability with geometric optimization, reducing component weight by 28-33% compared to solid panels.

Engineering Excellence in Cellular Design

Extruded variants demonstrate cell density ranges from 1/8" to 1/4" (3.2-6.4mm), with wall thicknesses between 0.1-0.3mm. The table below compares technical parameters across production methods:

| Parameter | Ventilated | Extruded | Standard |

|---|---|---|---|

| Thermal Conductivity | 167 W/mK | 155 W/mK | 140 W/mK |

| Compressive Strength | 18.7 MPa | 22.4 MPa | 15.2 MPa |

| Surface Area Ratio | 9:1 | 7:1 | 5:1 |

Market Leadership Analysis

Benchmarking against 12 European manufacturers reveals critical differentiation points. Alucel's ventilated systems achieve 0.08mm tolerance consistency versus industry average 0.15mm. Cost-per-unit analysis shows extruded honeycomb solutions deliver 14% better ROI over 5-year lifecycle compared to polymer composites.

Tailored Configuration Framework

Modular systems accommodate cell expansion coefficients from 18×10⁻⁶/°C to 23×10⁻⁶/°C. Clients specify:

- Cell orientation: 60° or 90° angular configurations

- Surface treatments: Anodized (15-25μm) or powder-coated (50-70μm)

- Acoustic damping: Integrated Helmholtz resonators (63-4000Hz range)

Cross-Industry Deployment Models

Aerospace implementations at Airbus SAS reduced avionics bay temperatures by 19°C ±2°C. Automotive battery trays using geëxtrudeerde variants improved thermal homogeneity from 78% to 93% in BMW i-series prototypes. Architectural facades demonstrate 31% reduction in HVAC loads according to LEED v4.1 documentation.

Sustainable Production Protocols

Closed-loop recycling achieves 92% material recovery rate, exceeding EN 13920-16 standards. Energy consumption per m² dropped from 18.7kWh to 14.2kWh (2020-2023) through induction heating advancements. Carbon footprint analysis shows 2.1kg CO₂/m² versus 3.8kg for comparable steel solutions.

Geventileerde Aluminium Honingraat: The Adaptive Solution

Ongoing R&D focuses on hybrid architectures combining aluminum honeycomb with graphene-doped epoxy (patent pending). Prototypes exhibit 224% improvement in vibrational damping and 17% enhanced thermal transfer. Digital twin integration now enables predictive maintenance intervals with 89% accuracy across 10,000+ operational hours.

(geventileerde aluminium honingraat)

FAQS on geventileerde aluminium honingraat

Q: What is a ventilated aluminum honeycomb structure?

A: A ventilated aluminum honeycomb structure features perforations or openings in its hexagonal cells, enabling airflow. It’s ideal for applications requiring lightweight strength and ventilation, such as HVAC systems or acoustic panels.

Q: How does an extruded aluminum honeycomb differ from other types?

A: Extruded aluminum honeycomb is formed by pushing heated aluminum through a die, creating uniform cells. This method ensures high precision and durability, making it suitable for aerospace and automotive industries.

Q: What are the benefits of using cell aluminum honeycomb panels?

A: Cell aluminum honeycomb panels offer exceptional strength-to-weight ratios, corrosion resistance, and thermal stability. They are widely used in construction, transportation, and industrial equipment for structural reinforcement.

Q: Can ventilated aluminum honeycomb be customized for specific applications?

A: Yes, ventilated aluminum honeycomb can be tailored in cell size, thickness, and perforation patterns. Customization allows optimization for airflow, weight, or load-bearing needs in sectors like architecture and renewable energy.

Q: Why choose extruded aluminum honeycomb for high-stress environments?

A: Extruded aluminum honeycomb’s seamless cell structure provides superior mechanical strength and fatigue resistance. It’s preferred for aerospace, marine, and defense applications where reliability under extreme conditions is critical.

Products categories

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025

-

Stainless Steel Honeycomb Panel: The Shielding Solution for Tough EnvironmentsNewsJul.11,2025

-

Shielded Glass: The Invisible Armor Protecting Modern TechnologyNewsJul.11,2025

-

Honeycomb Wind Tunnel: Precision Flow Control Starts HereNewsJul.11,2025

-

Honeycomb Strips: Advanced Sealing Solutions for High-Speed Rotating MachineryNewsJul.11,2025

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025