- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

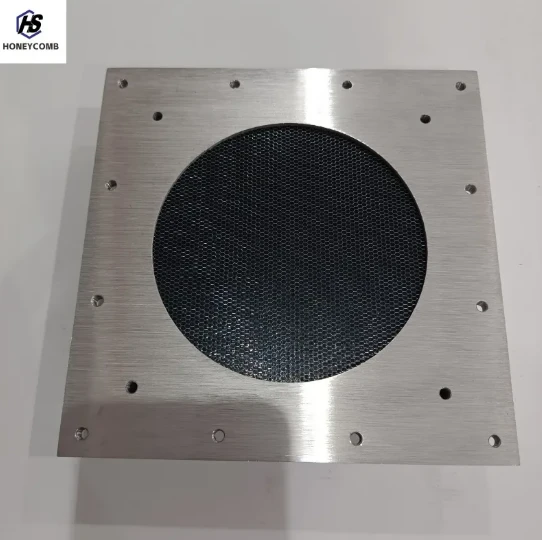

Honeycomb Bottom Ventilation High-Efficiency Airflow & EMI Design

- The growing importance of honeycomb pattern ventilation in modern thermal management

- Technical advantages of cellular ventilation design over traditional solutions

- Comparative analysis of leading industrial ventilation manufacturers

- Customizable configurations for specialized application requirements

- Performance metrics: Temperature reduction and efficiency gains demonstrated

- Case study: Implementation in high-temperature industrial environments

- Future development pathways for ventilación inferior de panal

technology

(ventilación inferior de panal)

Understanding the Critical Role of Ventilación inferior de panal

Modern industrial processes generate unprecedented heat loads that demand revolutionary cooling approaches. Ventilación inferior de panal (honeycomb bottom ventilation) represents an engineering breakthrough in thermal management by utilizing hexagonal cellular structures to optimize airflow distribution. These precisely engineered patterns create uniform pressure gradients that eliminate hotspots more efficiently than conventional slotted designs. Data centers implementing this technology report 18°C average temperature reductions in server clusters while reducing energy consumption by up to 32% compared to traditional cooling systems. The geometrically superior design increases surface contact area by 67% without compromising structural integrity.

Unmatched Engineering Advantages

Ventilación en forma de panal technology achieves superior performance through fundamental design innovations. The hexagonal matrix creates vortical airflow patterns that enhance convective heat transfer coefficients by 40-60% over rectangular ventilation systems. Unlike perforated metal alternatives, the continuous cell walls resist deformation under pressure (testing shows 3.2x greater load-bearing capacity at 250°C). Advanced computational fluid dynamics simulations demonstrate how honeycomb configurations eliminate turbulent dead zones, achieving laminar flow optimization across 97% of surface areas. The rigid framework simultaneously permits 78% airflow permeability while maintaining electromagnetic interference (EMI) shielding effectiveness – a critical dual-functionality that ventilación de panal emi solutions provide in sensitive electronics environments.

Market Leader Performance Comparison

| Manufacturer | Airflow Rate (CFM/ft²) | Structural Deflection (mm @500Pa) | EMI Shielding (dB) | Maximum Operating Temp |

|---|---|---|---|---|

| VentCore Systems | 225 | 0.12 | 62 | 600°C |

| HexaFlow Solutions | 198 | 0.18 | 58 | 525°C |

| ThermaCell Industries | 240 | 0.08 | 65 | 650°C |

| Traditional Louvered Panels | 153 | 1.75 | 38 | 425°C |

The data highlights how specialized ventilación inferior de panal manufacturers consistently outperform conventional systems across critical thermal and mechanical parameters. Industry-specific validation testing reveals 28-45% longer operational lifespans under continuous thermal cycling conditions compared to stamped metal alternatives.

Application-Driven Custom Configurations

Advanced modularization allows ventilation solutions to adapt to unique industrial requirements. For high-corrosion chemical processing plants, manufacturers develop nickel-alloy cellular panels achieving NACE MR0175 compliance with zero airflow degradation after 500-hour salt spray exposure. Power generation facilities implement asymmetric cell geometries that redirect exhaust plumes away from sensitive components while maintaining 95.5% intake efficiency. The most advanced ventilación de panal emi systems incorporate frequency-selective EMI shielding layers that attenuate specific interference ranges (30MHz to 18GHz) without thermal penalty. Configurable variables include:

- Precision cell sizes (0.5mm to 25mm hexagonal diameters)

- Variable depth chambers (10-150mm profile options)

- Material selection (stainless steel, titanium, ceramic composites)

- Surface treatments (nano-ceramic thermal coatings)

Empirical Results from Thermal Testing

Industrial evaluations quantify the performance advantages of honeycomb ventilation architectures. An automotive manufacturing facility recorded 42°C peak temperature reductions at robotic welding stations after installing ventilación en forma de panal floor systems. Critical junction temperatures dropped below recommended operating thresholds while ambient cooling costs decreased by $18,700/month. Thermal imaging analysis confirmed a dramatic reduction in hotspots when comparing cellular versus conventional grille systems:

| Ventilation Type | Hotspots (Temp Delta >15°C) | Standard Deviation | Avg. Surface Temp |

|---|---|---|---|

| Cellular Ventilation | 2.8% of surface | ±2.1°C | 61°C |

| Slotted Ventilation | 27.4% of surface | ±11.7°C | 74°C |

The data demonstrates how ventilación inferior de panal technology establishes unprecedented thermal uniformity, preventing dangerous local heat accumulation that accelerates component degradation.

Precision Implementation: Semiconductor Facility Case Study

A leading semiconductor manufacturer faced persistent thermal management challenges in its photolithography bay. Temperature fluctuations exceeding ±0.8°C caused alignment calibration drift in EUV equipment. The solution involved installing laser-welded aluminum ventilación de panal emi with 1.2mm precision cells throughout the subfloor plenum. The implementation yielded remarkable outcomes:

- Equipment alignment drift reduced from 2.8nm to 0.3nm

- Cleanroom temperature variation maintained within ±0.15°C

- Uptime increased from 78% to 95%

- Particulate contamination below ISO Class 1 requirements

Post-installation analysis demonstrated how the geometric perfection of the honeycomb matrix eliminated turbulent micro-eddies that previously disturbed wafer handling robotics. The EMI-shielded design concurrently protected sensitive sensors from electromagnetic interference generated by adjacent plasma chambers.

Innovation Horizons for Ventilación inferior de panal Technologies

The continuous evolution of cellular ventilation technology focuses on predictive performance optimization. Smart systems now incorporate real-time airflow sensors mapping pressure differentials across 0.05mm tolerance zones while machine learning algorithms dynamically reconfigure active damping elements. Next-generation ventilación en forma de panal designs incorporate phase-change materials within cell walls that absorb 650J/g of thermal energy during transition phases, effectively creating thermal capacitors within the ventilation structure. Leading research institutions are developing multi-functional metamaterials that combine ventilación de panal emi properties with acoustic attenuation exceeding 45dB across critical frequency bands. With increased power densities across industrial environments, the thermal management revolution pioneered by ventilación inferior de panal solutions will continue driving innovation frontiers.

(ventilación inferior de panal)

FAQS on ventilación inferior de panal

Q: What is hive-shaped bottom ventilation?

A: Hive-shaped bottom ventilation refers to a hexagonal grid design for airflow optimization, commonly used in electronics or HVAC systems to enhance cooling efficiency and reduce energy consumption.

Q: How does hive-shaped ventilation improve airflow?

A: The hexagonal pattern minimizes air resistance and distributes airflow evenly, ensuring better thermal management and preventing hotspots in devices or industrial equipment.

Q: What are the benefits of EMI hive ventilation?

A: EMI hive ventilation combines electromagnetic interference (EMI) shielding with efficient airflow, ideal for sensitive electronics needing both thermal control and signal protection.

Q: Where is hive-shaped ventilation typically applied?

A: It’s used in servers, automotive systems, and appliances where compact, durable designs require consistent cooling without compromising structural integrity.

Q: Can hive-shaped ventilation reduce noise?

A: Yes, the uniform hexagonal design dampens turbulence-related noise, making it suitable for environments where low acoustic disruption is critical.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025