- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 04:42

Back to list

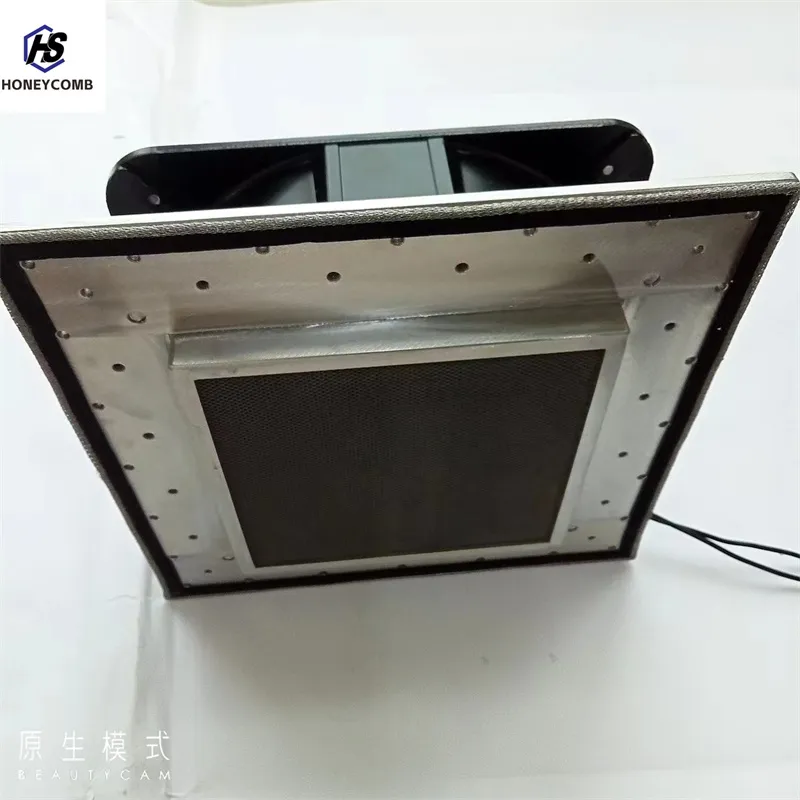

honeycomb in wind tunnel

Exploring the intricacies of honeycomb design in wind tunnel testing unveils a fascinating journey into the heart of aerodynamic optimization. The honeycomb, a naturally inspired structure, offers unique advantages when analyzed and implemented within aerodynamic studies. Combining the realms of nature, engineering, and technology, honeycomb structures have become instrumental in advancing aerodynamic designs across various industries, particularly in automotive and aerospace sectors.

Professionally, the significance of honeycomb design extends beyond aircraft components and automotive parts. The innovative application of these structures is evident in green energy, specifically in wind turbine blades and solar panels, highlighting their versatility. The honeycomb's ability to minimize weight while ensuring structural integrity translates into higher efficiency and durability, essential for sustainable technologies. Emerging research and computational fluid dynamics (CFD) simulations are pushing the boundaries of what is possible with honeycomb designs in aerodynamic settings. These simulations complement physical wind tunnel tests, offering the possibility to visualize and analyze different scenarios virtually. Enhanced computer modeling provides the capability to test numerous configurations and conditions rapidly, refining designs before physical prototypes are built and tested. Further establishing the authority of honeycomb technologies in aerodynamics, numerous leading academic institutions and research organizations are continually publishing studies that explore new materials, construction techniques, and innovative applications. Their findings keep setting new standards in aerodynamics, ensuring that honeycomb structures remain an integral part of future technological advancements. The undeniable trustworthiness of honeycomb designs in the field of aerodynamics can be attributed to the years of research and the practical outcomes they have delivered. Aerospace giants and automotive manufacturers have repeatedly proven their value, incorporating these designs in iconic projects that continue to redefine speed, efficiency, and performance. In summary, the honeycomb design's contribution to wind tunnel testing epitomizes the blend of natural inspiration and technological innovation. This synergy not only advances the understanding of aerodynamics but also paves the way for cutting-edge developments across industries. As research progresses, these structures are poised to offer even more groundbreaking solutions, maintaining their place at the forefront of engineering advancements.

Professionally, the significance of honeycomb design extends beyond aircraft components and automotive parts. The innovative application of these structures is evident in green energy, specifically in wind turbine blades and solar panels, highlighting their versatility. The honeycomb's ability to minimize weight while ensuring structural integrity translates into higher efficiency and durability, essential for sustainable technologies. Emerging research and computational fluid dynamics (CFD) simulations are pushing the boundaries of what is possible with honeycomb designs in aerodynamic settings. These simulations complement physical wind tunnel tests, offering the possibility to visualize and analyze different scenarios virtually. Enhanced computer modeling provides the capability to test numerous configurations and conditions rapidly, refining designs before physical prototypes are built and tested. Further establishing the authority of honeycomb technologies in aerodynamics, numerous leading academic institutions and research organizations are continually publishing studies that explore new materials, construction techniques, and innovative applications. Their findings keep setting new standards in aerodynamics, ensuring that honeycomb structures remain an integral part of future technological advancements. The undeniable trustworthiness of honeycomb designs in the field of aerodynamics can be attributed to the years of research and the practical outcomes they have delivered. Aerospace giants and automotive manufacturers have repeatedly proven their value, incorporating these designs in iconic projects that continue to redefine speed, efficiency, and performance. In summary, the honeycomb design's contribution to wind tunnel testing epitomizes the blend of natural inspiration and technological innovation. This synergy not only advances the understanding of aerodynamics but also paves the way for cutting-edge developments across industries. As research progresses, these structures are poised to offer even more groundbreaking solutions, maintaining their place at the forefront of engineering advancements.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025