- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

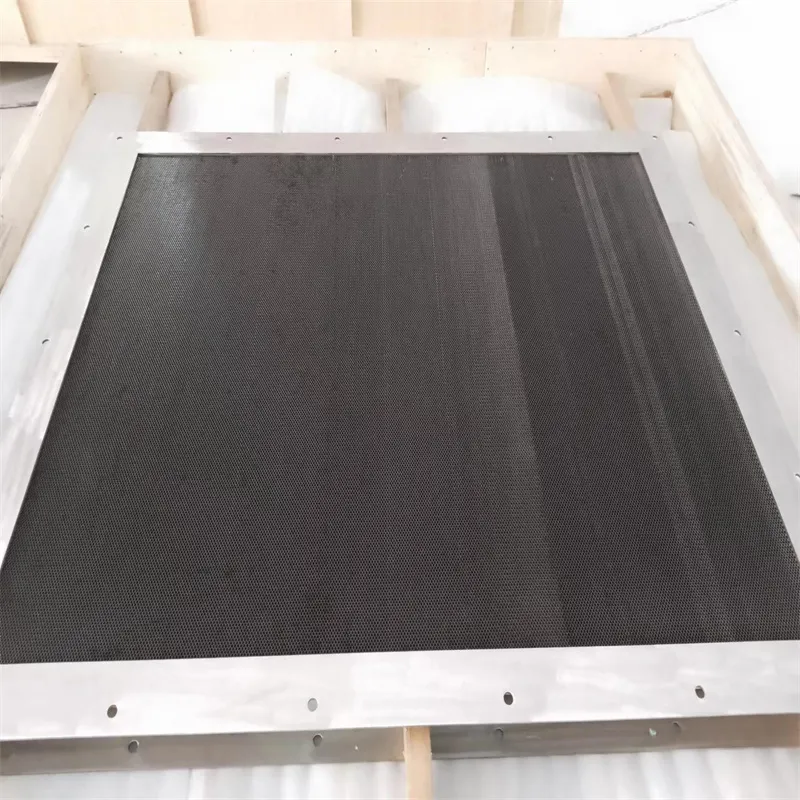

Aluminum Honeycomb Structures for Enhanced Strength and Lightweight Applications

The Advantages of Aluminium Honeycomb Structures

Aluminium honeycomb structures are gaining increasing popularity in various industries due to their unique combination of lightweight properties and exceptional strength. These structures resemble the natural hexagonal honeycomb design found in beehives, which is known for its efficiency and strength-to-weight ratio. This architectural marvel has found applications in sectors such as aerospace, automotive, construction, and even furniture design. In this article, we’ll explore the benefits of aluminium honeycomb materials, their applications, and why they represent a significant advancement in materials engineering.

Lightweight and Strong

One of the standout features of aluminium honeycomb structures is their remarkable strength-to-weight ratio. The hexagonal cell design enables the material to absorb significant amounts of stress while maintaining low overall weight. This makes aluminium honeycomb an ideal choice for industries where weight savings are critical, such as aerospace and automotive manufacturing. For instance, using aluminium honeycomb panels in aircraft can lead to enhanced fuel efficiency and reduced emissions, as lighter aircraft require less power to achieve the same performance.

Robustness and Durability

Aluminium is naturally resistant to corrosion, and when paired with the honeycomb design, it provides an exceptionally robust and durable material. This durability is crucial in various applications, especially in environments where materials may be exposed to harsh conditions. For example, aluminium honeycomb structures are often utilized in marine environments due to their resistance to saltwater corrosion. Additionally, their impact resistance makes them suitable for high-traffic areas in commercial constructions, ensuring longevity and minimal maintenance costs.

Versatile Applications

The versatility of aluminium honeycomb structures is evident in their wide range of applications. In the aerospace industry, they are commonly used in aircraft interiors, wing structures, and cargo floors. Their lightweight nature helps in reducing overall aircraft weight, thus improving fuel efficiency. In the automotive industry, honeycomb panels are utilized in vehicle interiors, helping to reduce weight without compromising safety and integrity.

zellenwaben aus aluminium

In the construction sector, aluminium honeycomb panels are used in walls and facades, providing excellent insulation and aesthetic appeal. Additionally, they can be found in the furniture industry, where honeycomb cores are used to create lightweight and sturdy tabletops and cabinets. The ease of fabrication and customization of aluminium honeycomb structures allows designers and engineers to create innovative solutions that meet specific needs.

Environmental Benefits

As sustainability becomes increasingly important in design and manufacturing, aluminium honeycomb structures offer significant environmental advantages. Aluminium is 100% recyclable, which means that products made from this material can be reused without losing their inherent properties. This characteristic contributes to a circular economy, minimizing waste and reducing the environmental footprint of manufacturing processes.

Moreover, the energy efficiency provided by lighter structures helps reduce overall energy consumption in transportation and building applications. This has made aluminium honeycomb a preferred choice for companies looking to meet sustainability targets while optimizing performance.

Advanced Engineering Solutions

Recent advancements in manufacturing techniques have further propelled the use of aluminium honeycomb structures. Innovations such as automated production lines and computer-aided design tools have made it easier to create complex geometries, ensuring that the panels meet specific performance requirements. This means that engineers can tailor the thickness, density, and size of honeycomb cores to suit a variety of applications, enhancing their performance further.

In conclusion, aluminium honeycomb structures exemplify the perfect blend of strength, lightweight design, durability, and versatility. Their applications across multiple industries highlight their significance in modern engineering solutions. As industries continue to focus on reducing weight and improving sustainability, the use of aluminium honeycomb materials is likely to increase, paving the way for innovative designs and more efficient products. Whether in the air, on the road, or in our buildings, aluminium honeycomb panels stand out as a testament to human ingenuity in materials science.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025