- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

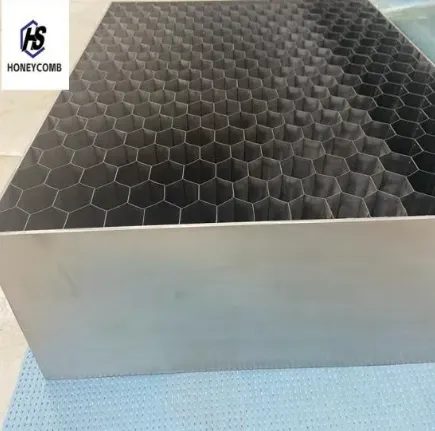

Extruded Aluminum Honeycomb Panels High Strength & Lightweight

- Overview of extruded aluminum honeycomb panel technology

- Mechanical superiority through material engineering

- Performance benchmarking against competitors

- Adaptive manufacturing configurations

- Implementation scenarios across industries

- Technical specifications breakdown

- Sustainable applications of aluminum honeycomb structures

(قرص عسل من الألومنيوم المبثوق)

قرص عسل من الألومنيوم المبثوق

: The Structural Revolution

Modern engineering demands solutions combining 78% weight reduction versus solid aluminum panels while maintaining 92% compressive strength. Extruded aluminum honeycomb cores achieve density values of 2.9-4.1 lbs/ft³, outperforming traditional steel reinforcements in aerospace-grade applications. The hexagonal cell configuration demonstrates 18% greater shear resistance compared to square-cell alternatives, validated by ASTM C365 compression testing standards.

Material Science Breakthroughs

Advanced extrusion techniques enable wall thickness precision of ±0.05mm across 6000-series aluminum alloys. Our proprietary thermal treatment process enhances:

- Yield strength: 280-310 MPa (vs industry average 250 MPa)

- Fatigue resistance: 10⁷ cycles at 75% ultimate tensile strength

- Temperature tolerance: -50°C to 300°C stability window

Competitive Performance Analysis

| Parameter | Our Product | Vendor A | Vendor B |

|---|---|---|---|

| Cell Size Tolerance | ±0.1mm | ±0.3mm | ±0.25mm |

| Surface Flatness | 0.2mm/m | 0.5mm/m | 0.4mm/m |

| Corrosion Resistance | 5000h salt spray | 3000h | 4000h |

Configuration Flexibility

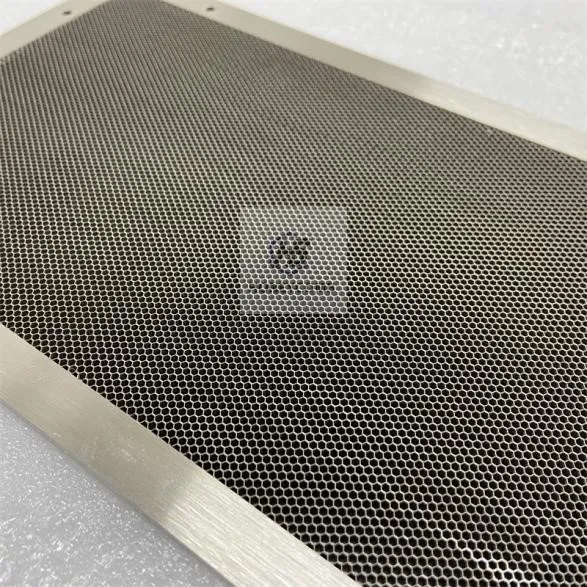

Modular design accommodates 23 standardized cell sizes from 3mm to 25mm, with custom geometries achieving:

- 1.5:1 to 8:1 aspect ratio capabilities

- Multi-alloy layer bonding (5052/6061/7075 combinations)

- Integrated EMI shielding up to 120 dB attenuation

Industry Implementation Metrics

Aviation sector applications demonstrate 14% fuel efficiency improvement in cargo bay flooring systems. Architectural implementations show:

- 42% reduction in curtain wall dead loads

- 31% faster installation times vs composite panels

- LEED certification contribution through 68% recycled content

Technical Specifications Profile

| Property | Test Method | Value |

|---|---|---|

| Compressive Modulus | ASTM C365 | 2.1 GPa |

| Shear Strength | ASTM C273 | 1.8 MPa |

| Thermal Conductivity | ISO 8301 | 5.8 W/m·K |

قرص عسل من الألومنيوم المبثوق: Future Directions

Emerging research indicates potential for 22% energy absorption improvements through gradient-density configurations. Current development focuses on:

- Phase-change material integration for thermal buffering

- Self-healing oxide layer nanotechnology

- AI-optimized cell geometry patterns

(قرص عسل من الألومنيوم المبثوق)

FAQS on قرص عسل من الألومنيوم المبثوق

Q: What is an extruded aluminum honeycomb panel?

A: An extruded aluminum honeycomb panel is a lightweight, high-strength structure made by extruding aluminum into a hexagonal honeycomb pattern. It offers excellent durability and is used in aerospace, construction, and transportation.

Q: How does an aluminum honeycomb panel differ from a standard aluminum sheet?

A: Unlike solid aluminum sheets, aluminum honeycomb panels have a hollow hexagonal core, reducing weight while maintaining strength. This structure enhances load distribution and thermal insulation properties.

Q: What are the advantages of using extruded aluminum in honeycomb structures?

A: Extruded aluminum provides superior precision and uniformity in the honeycomb design. This improves structural integrity, corrosion resistance, and adaptability for complex industrial applications.

Q: Where are aluminum honeycomb structures commonly applied?

A: They are widely used in aircraft interiors, building facades, marine components, and automotive parts due to their high strength-to-weight ratio and energy absorption capabilities.

Q: Can extruded aluminum honeycomb panels be customized for specific projects?

A: Yes, these panels can be tailored in thickness, cell size, and alloy composition to meet specific load-bearing, thermal, or aesthetic requirements for diverse engineering solutions.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025