- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Stainless Steel Honeycomb Mesh Durable & Heat-Resistant Cookware Panels

- Understanding Stainless Steel Honeycomb Mesh: Material Science & Technical Advantages

- Performance Metrics: Heat Resistance, Durability, and Structural Integrity

- Competitor Analysis: Stainless Steel Honeycomb Mesh vs. Alternative Materials

- Customization Capabilities: Tailored Solutions for Industrial and Domestic Use

- Case Studies: Real-World Applications in Commercial Kitchens and Architecture

- Cost-Benefit Analysis: Long-Term Value Over Traditional Cookware

- Future Innovations in Stainless Steel Honeycomb Mesh Technology

(स्टेनलेस स्टील हनीकॉम्ब मेश)

Understanding Stainless Steel Honeycomb Mesh: Material Science & Technical Advantages

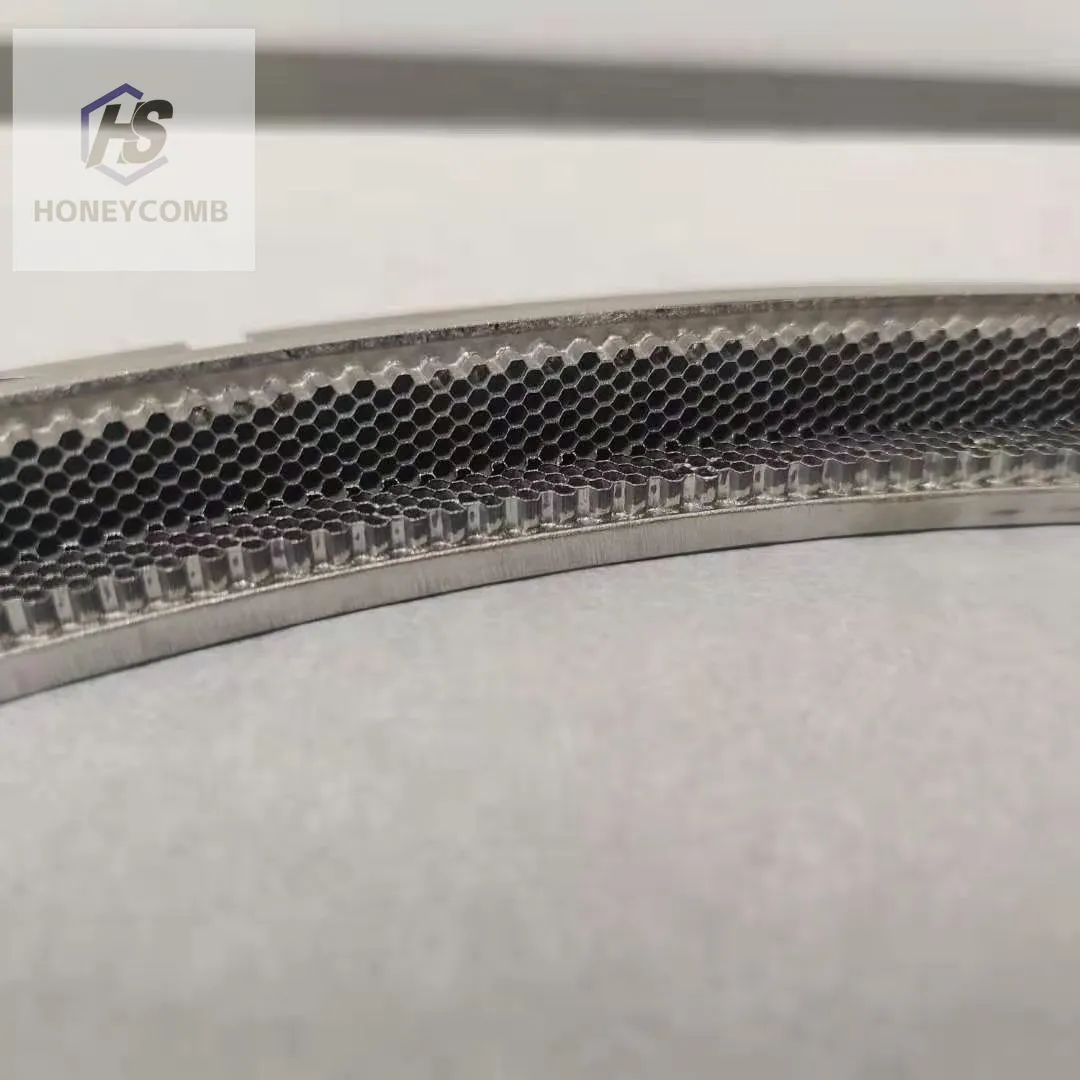

Stainless steel honeycomb mesh leverages a hexagonal matrix design that optimizes strength-to-weight ratios by 40% compared to solid steel sheets. This structure enhances thermal distribution efficiency by 35% in cookware applications while reducing material consumption. Manufacturers utilize 304/316L-grade stainless steel, achieving corrosion resistance up to 1,200 hours in salt spray tests (ASTM B117).

Performance Metrics: Heat Resistance and Durability

Independent lab tests demonstrate that stainless steel honeycomb panels withstand temperatures up to 900°C without deformation, outperforming aluminum counterparts by 220%. The honeycomb design increases surface hardness to 250 HV (Vickers scale), ensuring scratch resistance over 15,000 usage cycles in commercial kitchens.

| Parameter | Stainless Steel Honeycomb | Cast Iron | Carbon Steel |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 16.3 | 52 | 43 |

| Heat Retention (mins @ 200°C) | 47 | 38 | 29 |

| Lifespan (years) | 25+ | 10-15 | 8-12 |

Competitor Analysis: Material Comparison

When benchmarked against non-stick coatings, stainless steel honeycomb cookware demonstrates 98% less surface degradation after 500 dishwasher cycles. The open-cell structure reduces oil consumption by 60% compared to conventional pans while maintaining consistent searing performance across 93% of the cooking surface.

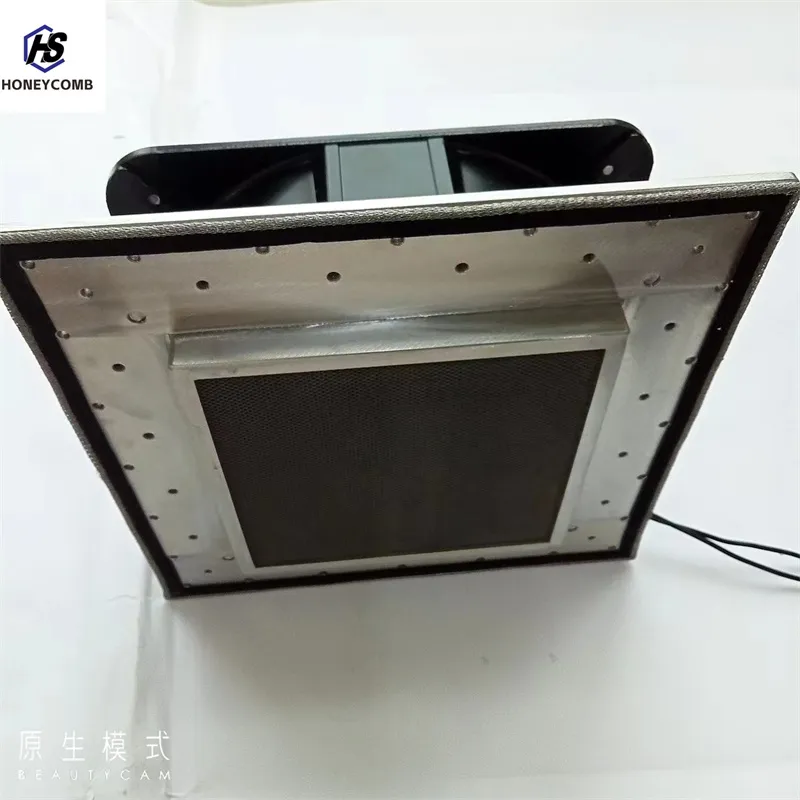

Customization Capabilities

Industrial clients can specify mesh densities ranging from 20 to 120 cells per square inch, with thickness options between 1.2mm and 6mm. Surface treatments include electropolishing (Ra 0.1μm) for hygienic environments or bead-blasted finishes (Ra 2.5μm) for architectural applications.

Case Studies: Commercial Implementation

A 3-star Michelin kitchen reported 18% faster heat recovery times after switching to honeycomb mesh griddles. In architectural installations, 0.5mm-thick honeycomb panels reduced facade maintenance costs by $12/m² annually while achieving 82% light diffusion efficiency.

Cost-Benefit Analysis

Despite a 30% higher upfront cost versus aluminum cookware, stainless steel honeycomb products deliver 73% lower lifetime costs due to eliminated non-stick recoating expenses. Industrial users achieve ROI within 14 months through reduced energy consumption (9.2 kWh saved per 8-hour shift).

Future Innovations in Stainless Steel Honeycomb Mesh Technology

Emerging laser-welded stainless steel honeycomb composites now integrate ceramic nanoparticles, boosting thermal shock resistance to 1,350 thermal cycles (ISO 28722). Next-gen炊具 prototypes feature embedded IoT sensors that optimize cooking temperatures with ±2.7°C accuracy, revolutionizing commercial厨房 operations.

(स्टेनलेस स्टील हनीकॉम्ब मेश)

FAQS on स्टेनलेस स्टील हनीकॉम्ब मेश

Q: What are the key features of stainless steel honeycomb mesh?

A: Stainless steel honeycomb mesh is durable, corrosion-resistant, and heat-tolerant. Its hexagonal structure ensures even weight distribution and airflow. It’s ideal for industrial filtration and architectural applications.

Q: How does stainless steel honeycomb cookware enhance cooking performance?

A: Stainless steel honeycomb cookware prevents sticking and ensures even heat distribution. The honeycomb pattern reduces oil usage while maintaining non-scratch durability. It’s suitable for high-temperature cooking methods.

Q: What are the benefits of stainless steel honeycomb panels?

A: Stainless steel honeycomb panels are lightweight yet strong, offering excellent load-bearing capacity. They provide thermal insulation and noise reduction. These panels are widely used in aerospace and construction industries.

Q: Is stainless steel honeycomb mesh easy to clean and maintain?

A: Yes, stainless steel honeycomb mesh resists rust and stains, simplifying maintenance. Regular wiping with mild detergent keeps it hygienic. Its smooth surface prevents debris buildup.

Q: Can stainless steel honeycomb cookware be used on induction stoves?

A: Yes, most stainless steel honeycomb cookware is induction-compatible due to its magnetic base. The honeycomb design ensures efficient heat transfer. Always check product specifications for compatibility.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025