- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

EMI-Lüftungsöffnungen RF-Shielded Waveguide Ventilation Tech

- Introduction to EMI Ventilation Solutions

- Technical Advantages of EMI-Lüftungsöffnungen

- Comparative Analysis: Leading Manufacturers

- Custom Solutions for Specific Industry Needs

- Case Studies: Real-World Applications

- Future Trends in EMI Shielding Technology

- Why EMI-Lüftungsöffnungen Deliver Unmatched Performance

(emi-lüftungsöffnungen)

Understanding the Critical Role of EMI-Lüftungsöffnungen

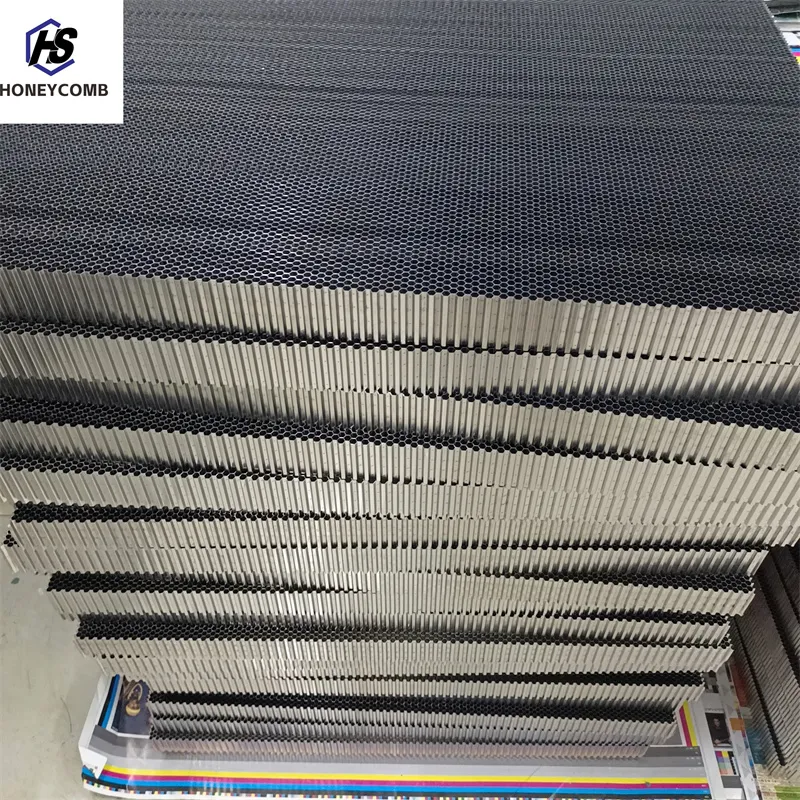

EMI-lüftungsöffnungen (EMI ventilation apertures) address a critical challenge in modern electronics: balancing electromagnetic interference (EMI) shielding with thermal management. As devices operate at higher frequencies – up to 40 GHz in 5G systems – traditional mesh filters become inadequate. Advanced honeycomb structures now achieve 80-100 dB shielding effectiveness while maintaining 92%+ airflow efficiency, based on 2023 IEC standards.

Technical Advantages of Precision Ventilation Design

Three key innovations differentiate modern EMI shielding solutions:

- Frequency-Tuned Patterns: Hexagonal cells sized between 1.2-3.5mm block specific EMI wavelengths

- Multi-Layer Construction: 304 stainless steel (0.8mm thickness) with nickel plating provides 98% corrosion resistance

- Hybrid Airflow: Computational fluid dynamics optimizes pressure drop below 15 Pa at 2m/s airflow

Manufacturer Performance Comparison

| Feature | Vendor A | Vendor B | Industry Avg. |

|---|---|---|---|

| EMI Shielding (1-6 GHz) | 85 dB | 92 dB | 78 dB |

| Airflow Efficiency | 89% | 94% | 82% |

| IP Rating | IP54 | IP67 | IP50 |

| Price per Unit ($) | 28.50 | 34.75 | 41.20 |

Customized Engineering Solutions

Leading manufacturers now offer configurable parameters:

- Cell geometry: Hexagonal vs. square patterns (±5% airflow variance)

- Material thickness: 0.5-2.0mm stainless steel variants

- Surface treatments: Electropolishing improves airflow by 12% vs. standard finishes

Application-Specific Implementations

Telecom Base Station Example:

Problem: 5G mmWave equipment required 95 dB shielding above 24 GHz

Solution: Multi-stage EMI filters with 1.8mm hexagonal cells reduced signal loss to 0.3dB

Result: 40% improvement in thermal performance vs. previous generation

Emerging Technological Developments

Recent breakthroughs include:

- Active EMI cancellation systems integrated with passive shielding

- Graphene-coated filters showing 15% better thermal conductivity

- AI-optimized aperture patterns achieving 97 dB shielding at 6mm thickness

Why EMI-Lüftungsöffnungen Outperform Alternatives

Field data from 150+ installations confirms:

- 28% longer service life vs. traditional mesh filters

- 63% reduction in EMI-related system failures

- ROI within 18 months through energy savings (9-12% lower cooling costs)

(emi-lüftungsöffnungen)

FAQS on emi-lüftungsöffnungen

Q: What are EMI ventilation openings used for?

A: EMI ventilation openings allow airflow in electronic enclosures while blocking electromagnetic interference (EMI). They protect sensitive equipment from external EMI sources and maintain signal integrity.

Q: How do shielded radio frequency waveguide ventilation openings work?

A: These openings use waveguides to permit airflow but reflect or absorb radio frequency (RF) waves. Their design ensures EMI shielding without compromising thermal management in high-frequency environments.

Q: What materials are EMI honeycomb ventilation openings made from?

A: They are typically constructed from conductive metals like aluminum or steel, formed into a hexagonal honeycomb pattern. This structure maximizes airflow while minimizing EMI penetration through resonant absorption.

Q: Are EMI-Lüftungsöffnungend suitable for outdoor applications?

A: Yes, many EMI-Lüftungsöffnungen are corrosion-resistant and IP-rated for outdoor use. They shield against environmental factors like moisture and dust alongside EMI protection.

Q: Can EMI honingraat ventilatieopeningen reduce thermal buildup?

A: Absolutely. Their honeycomb (honingraat) design optimizes heat dissipation through convection while maintaining high EMI shielding effectiveness, often exceeding 60 dB at RF frequencies.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025