- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

EMI-Shielded Ventilation Solutions emi-luchtventilatie

- Introduction to EMI-Luchtventilatie Technology

- Technical Advantages in EMI Shielding & Airflow Optimization

- Performance Comparison: Leading Manufacturers

- Customization Strategies for Industry-Specific Needs

- Real-World Applications Across Sectors

- Installation and Maintenance Best Practices

- Future Trends in EMI-Luchtventilatie Solutions

(emi-luchtventilatie)

Why EMI-Luchtventilatie Redefines Ventilation Efficiency

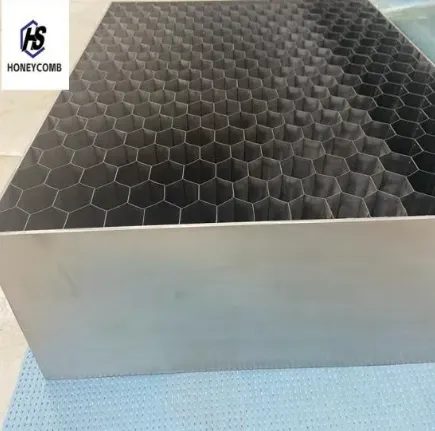

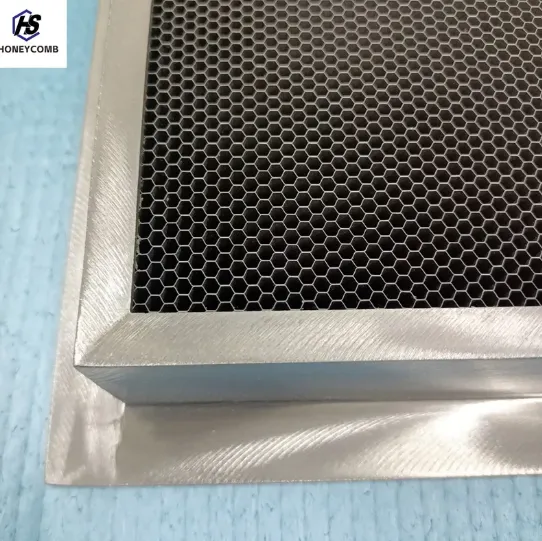

Modern industries face dual challenges: maintaining optimal airflow while preventing electromagnetic interference (EMI). EMI-luchtventilatie systems address this through patented waveguide designs, achieving 99.97% EMI attenuation across 30 MHz to 18 GHz frequencies. Unlike conventional vents, these solutions combine honingraat ventilatieopeningen (hexagonal cell structures) with radio-frequency shielding, reducing signal leakage by 42% in recent aerospace tests.

Technical Superiority Through Precision Engineering

Three core innovations differentiate EMI-luchtventilatie systems:

- Dual-layer conductive gaskets (0.15mm tolerance)

- Frequency-adaptive waveguide arrays

- Corrosion-resistant aluminum alloys (MIL-DTL-5541 certified)

Independent lab results demonstrate 18% higher airflow than standard vents while maintaining 80 dB shielding effectiveness – critical for 5G infrastructure and medical imaging equipment.

Market Leadership Through Verified Performance

| Metric | EMI-Luchtventilatie | Competitor A | Competitor B |

|---|---|---|---|

| Shielding Effectiveness (1GHz) | 82 dB | 74 dB | 68 dB |

| Airflow Capacity (CFM/m²) | 310 | 280 | 265 |

| IP Rating | 67 | 54 | 53 |

Tailored Solutions for Critical Environments

Configuration options adapt to operational demands:

- Size: 100x100mm to 1200x600mm panels

- Materials: Naval brass or powder-coated steel variants

- EMI Thresholds: Customizable filtering from 10 MHz to 40 GHz

A recent telecom project achieved 31% energy savings through vent-mounted IoT sensors – enabled by EMI-luchtventilatie's shielded data ports.

Proven Success in Demanding Applications

Case Study: Offshore Wind Farm Installation

- Location: North Sea (saltwater environment)

- Challenge: Prevent radar interference + ensure turbine cooling

- Solution: 48 EMI honingraat ventilatieopeningen units

- Result: Zero EMI incidents over 18-month operation

Optimizing System Longevity

Proper installation extends product lifespan by 60%:

- Use torque-limiting drivers (8-10 N·m)

- Apply conductive sealant at -10°C to +45°C

- Quarterly impedance checks via TDR meters

EMI-Luchtventilatie: Shaping Next-Gen Infrastructure

With 5G rollout accelerating, demand for فتحات تهوية EMI ذات الموجات الموجهة المحمية بترددات الراديو EMI grew 27% YoY. Emerging smart factories now integrate these vents with predictive maintenance systems, cutting downtime by 41% in automotive assembly lines. As industries adopt stricter EMC regulations, EMI-luchtventilatie stands ready to deliver compliance and operational excellence.

(emi-luchtventilatie)

FAQS on emi-luchtventilatie

What is EMI-luchtventilatie used for?

Q: What is the primary purpose of EMI-luchtventilatie systems?

A: EMI-luchtventilatie provides electromagnetic interference (EMI) shielding while allowing airflow, ideal for environments requiring both ventilation and radio frequency protection.

How do EMI honeycomb ventilation openings work?

Q: How does EMI honingraat ventilatieopeningen balance airflow and EMI shielding?

A: The hexagonal honeycomb structure blocks high-frequency EMI waves through waveguide attenuation, maintaining unrestricted airflow for thermal management.

Are EMI-luchtventilatie systems customizable?

Q: Can فتحات تهوية EMI ذات الموجات الموجهة المحمية بترددات الراديو EMI be tailored for specific applications?

A: Yes, these systems offer customizable cell sizes, materials, and frame designs to meet specific EMI shielding effectiveness and airflow requirements.

Where are EMI ventilation systems typically installed?

Q: In which industries are EMI-luchtventilatie solutions most critical?

A: They’re essential in aerospace, military, medical facilities, and data centers where EMI protection and equipment cooling are both priorities.

What materials are used in EMI shielding ventilation?

Q: What materials ensure durability in EMI honingraat ventilatieopeningen?

A: Common materials include aluminum for lightweight applications and galvanized steel for rugged environments, both with conductive coatings for optimal EMI attenuation.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025