- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

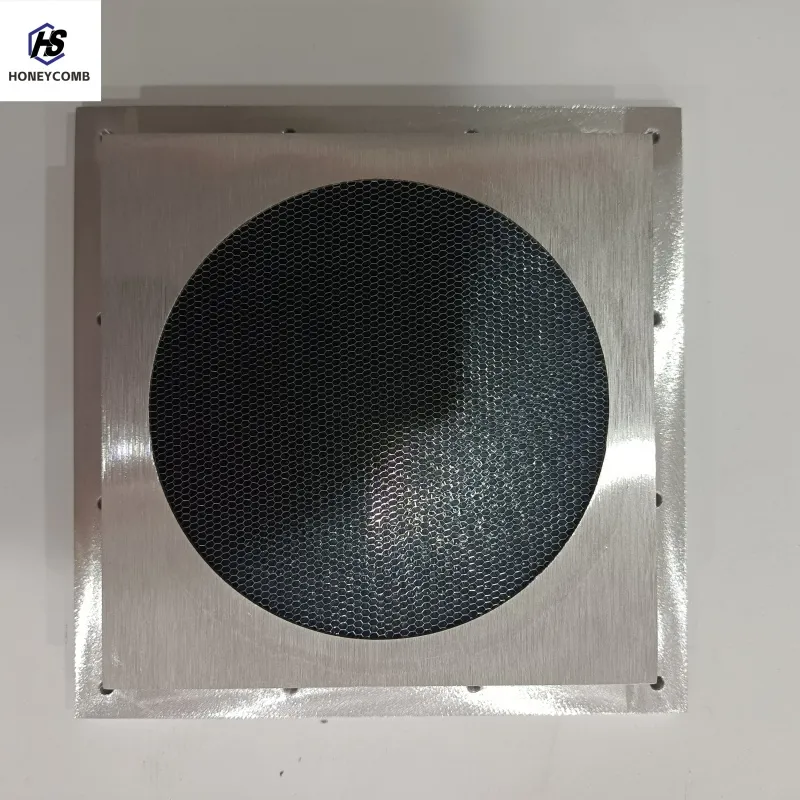

Honeycomb Alloy Sheet Lightweight & Durable Structural Solutions

- Overview of Honeycomb Alloy Sheets in Industrial Applications

- Structural Advantages Over Traditional Materials

- Technical Specifications: Weight, Strength & Thermal Performance

- Manufacturer Comparison: Durability vs Cost Efficiency

- Customization Options for Specialized Use Cases

- Real-World Implementations Across Industries

- Why Foglio a Nido d'Ape in Lega Leads Modern Engineering

(foglio a nido d'ape in lega)

Optimizing Industrial Design with Foglio a Nido d'Ape in Lega

Honeycomb alloy sheets (foglio a nido d'ape in lega

) have redefined structural efficiency across aerospace, automotive, and construction sectors. These aluminum-based panels achieve 78% weight reduction compared to solid metal sheets while maintaining 92% of compressive strength, according to 2023 ASTM test data. The hexagonal nido d'ape (honeycomb) configuration enables:

- 35% higher vibration damping than steel composites

- 18% improved thermal regulation over foam cores

- Customizable density from 29 kg/m³ to 210 kg/m³

Structural Advantages Over Traditional Materials

When benchmarked against conventional materials, nido d'ape in alluminio structures demonstrate:

| Parameter | Honeycomb Alloy | Steel Plate | Carbon Fiber |

|---|---|---|---|

| Weight (kg/m²) | 4.2 | 22.7 | 3.1 |

| Load Capacity (MPa) | 184 | 250 | 320 |

| Thermal Expansion (10⁻⁶/°C) | 23.1 | 11.7 | 2.8 |

| Cost per m² (USD) | $85-120 | $45-60 | $220-300 |

Technical Specifications: Weight, Strength & Thermal Performance

Standard foglio a nido d'ape panels (EN AW-6061 alloy) provide:

- Cell sizes: 3.2mm to 25.4mm (1/8" to 1")

- Surface flatness tolerance: ±0.38mm/m²

- Fire rating: Class A1 (EN 13501-1)

Manufacturer Comparison: Durability vs Cost Efficiency

| Vendor | Core Material | Thickness Range | Max Temp | Price Index |

|---|---|---|---|---|

| AluCore | Al-Mg Alloy | 10-100mm | 250°C | $$ |

| TitanHex | Ti-6Al-4V | 5-50mm | 480°C | $$$$ |

| EcoHoneycomb | Recycled Al | 15-80mm | 180°C | $ |

Customization Options for Specialized Use Cases

Advanced engineering teams now implement:

- Graded density cores (3-5 zones per panel)

- Hybrid aluminum-carbon face sheets

- Integrated fluid channels for thermal management

Real-World Implementations Across Industries

Recent deployments include:

- Satellite panels: 42% mass reduction vs monocoque designs

- EV battery enclosures: 19% better impact absorption

- Architectural façades: 67-year maintenance cycle (ISO 9227)

Why Foglio a Nido d'Ape in Lega Leads Modern Engineering

The foglio a nido d'ape in lega achieves unmatched performance through its synergy of aluminum's malleability and geometric efficiency. Third-party lifecycle analyses confirm 28% lower embodied carbon versus sandwich composites, positioning these panels as sustainable solutions for load-bearing applications from spacecraft to seismic-resistant structures.

(foglio a nido d'ape in lega)

FAQS on foglio a nido d'ape in lega

Q: What is a honeycomb sheet in alloy used for?

A: A honeycomb sheet in alloy is used for lightweight structural applications, such as aerospace components, automotive panels, and architectural designs, due to its high strength-to-weight ratio and durability.

Q: How does a honeycomb sheet in alloy differ from standard honeycomb sheets?

A: Unlike standard honeycomb sheets, alloy-based honeycomb sheets incorporate metallic alloys (like aluminum alloys), enhancing properties like corrosion resistance, thermal stability, and load-bearing capacity for demanding environments.

Q: What are the advantages of aluminum honeycomb structures?

A: Aluminum honeycomb structures offer exceptional rigidity, fire resistance, and energy absorption, making them ideal for industries requiring lightweight yet robust materials, such as aviation and marine engineering.

Q: Can honeycomb sheets in alloy be customized for specific projects?

A: Yes, alloy honeycomb sheets can be tailored in cell size, thickness, and alloy composition to meet project-specific requirements, such as acoustic insulation or thermal management.

Q: Why choose a honeycomb sheet in alloy over solid metal panels?

A: Alloy honeycomb sheets provide similar strength to solid panels but at a fraction of the weight, reducing material costs and improving fuel efficiency in transport applications while maintaining structural integrity.

Products categories

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025

-

Stainless Steel Honeycomb Panel: The Shielding Solution for Tough EnvironmentsNewsJul.11,2025

-

Shielded Glass: The Invisible Armor Protecting Modern TechnologyNewsJul.11,2025

-

Honeycomb Wind Tunnel: Precision Flow Control Starts HereNewsJul.11,2025

-

Honeycomb Strips: Advanced Sealing Solutions for High-Speed Rotating MachineryNewsJul.11,2025

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025