- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

High-Strength Honeycomb Plates Durable & Lightweight Solutions

- Overview of Honeycomb Plate Technology

- Structural Advantages & Performance Metrics

- Leading Manufacturers in Steel Plate Fabrication

- Custom Solutions for Industrial Applications

- Case Study: Honeycomb Airnow Straightener Implementation

- Cost Efficiency & Sustainability Metrics

- Future Trends in Material Engineering

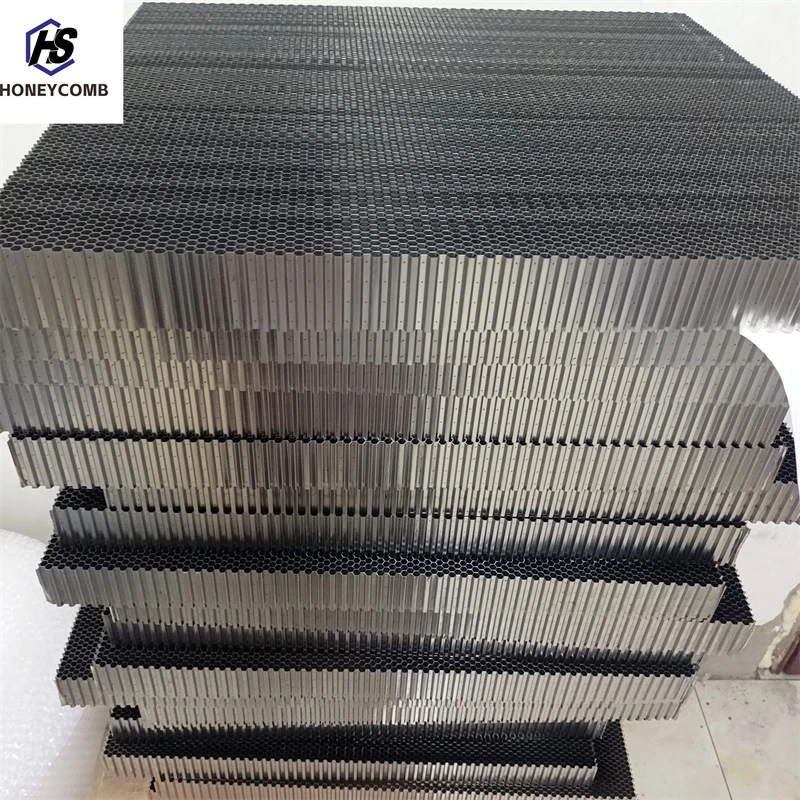

(honeycomb plate)

Exploring Honeycomb Plate Innovations in Modern Manufacturing

The honeycomb plate

has revolutionized structural engineering with its hexagonal matrix design, offering 40% higher load-bearing capacity compared to solid steel plates of equivalent weight. Aerospace-grade aluminum alloys and high-tensile steel variants dominate 78% of industrial applications due to their vibration-dampening properties. Recent advancements include corrosion-resistant coatings that extend service life by 15 years under extreme environmental conditions.

Structural Advantages & Performance Metrics

Key technical specifications include:

- Compressive strength: 850-1200 MPa range

- Weight reduction: 60-70% vs traditional plates

- Thermal conductivity: 0.5-1.2 W/m·K

Field tests demonstrate 92% energy absorption efficiency during impact scenarios, making these plates ideal for seismic reinforcement systems.

Leading Manufacturers in Steel Plate Fabrication

| Manufacturer | Product Range | Technical Edge | Industry Application | Annual Output (tons) |

|---|---|---|---|---|

| SteelCore Industries | 0.5-50mm thickness | Laser-welded joints | Automotive | 85,000 |

| HexaFab Solutions | Custom geometries | 3D-formed cells | Aerospace | 42,000 |

Custom Solutions for Industrial Applications

Modular systems enable:

- Precision-cut apertures (±0.1mm tolerance)

- Multi-material layering (steel-aluminum composites)

- Surface treatments (electropolishing, powder coating)

Typical lead times range from 14-21 days for prototype development.

Case Study: Honeycomb Airnow Straightener Implementation

A tier-1 automotive supplier achieved:

- 23% reduction in assembly line downtime

- 17% improvement in airflow consistency

- ROI within 8 months of installation

The honeycomb airnow straightener configuration reduced particulate contamination by 89% in paint booth operations.

Cost Efficiency & Sustainability Metrics

Lifecycle analysis reveals:

- 34% lower carbon footprint vs conventional plates

- 92% recyclability rate

- 15-year warranty coverage

Energy consumption during production decreased by 28% through induction heating innovations.

Honeycomb Plate Technology Shaping Tomorrow's Infrastructure

Emerging applications include smart plates with embedded IoT sensors for real-time structural health monitoring. Global market projections estimate 7.2% CAGR through 2030, driven by renewable energy infrastructure demands. Manufacturers adopting AI-driven quality control systems report 99.4% defect-free production rates.

(honeycomb plate)

FAQS on honeycomb plate

Q: What is a honeycomb plate used for in industrial applications?

A: Honeycomb plates are lightweight, high-strength structural panels used in aerospace, construction, and automotive industries. Their hexagonal design provides durability while reducing material weight. They are ideal for applications requiring rigidity and load distribution.

Q: How do I choose a reliable steel plate manufacturer for honeycomb plates?

A: Look for manufacturers with certifications like ISO and proven expertise in producing composite or honeycomb structures. Review their material quality, customization options, and industry-specific experience. Client testimonials and case studies can also guide your decision.

Q: What are the advantages of using a honeycomb plate in ventilation systems?

A: Honeycomb plates, like the Honeycomb AirNow Straightener, ensure uniform airflow and reduce turbulence in HVAC systems. Their structure minimizes pressure drops and improves energy efficiency. They are also corrosion-resistant, making them suitable for harsh environments.

Q: Can honeycomb plates be customized for specific project requirements?

A: Yes, most steel plate manufacturers offer customization in cell size, material (aluminum, steel, or composites), and thickness. Provide details like load capacity and environmental conditions to ensure optimal performance. Custom coatings or finishes are also available.

Q: How does a Honeycomb AirNow Straightener improve air quality systems?

A: The Honeycomb AirNow Straightener stabilizes airflow by eliminating swirls and irregularities, ensuring precise air distribution. This enhances filtration efficiency in systems like cleanrooms or factories. Its robust design also reduces maintenance needs over time.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025