- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

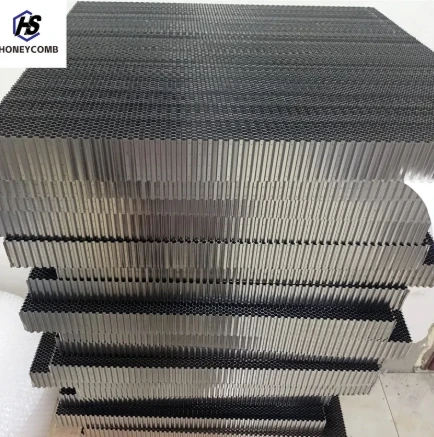

Metal Honeycomb Panels Lightweight, Durable & High-Strength Solutions

- Introduction to Metal Honeycomb Panels

- Technical Advantages Over Traditional Materials

- Market Comparison: Leading Manufacturers

- Customization Options for Diverse Applications

- Performance Data and Industry Benchmarks

- Real-World Implementation Case Studies

- Future Prospects of Painéal Meala Miotail Solutions

(painéal meala miotail)

Understanding Painéal Meala Miotail Core Technology

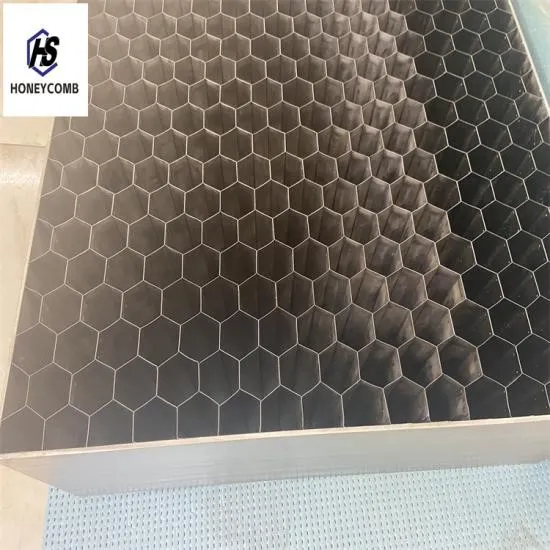

Metal honeycomb panels (painéal meala miotail

) revolutionize structural engineering with their hexagonal cell design, achieving 92% material efficiency compared to 67% in solid metal sheets. The leathán miotail honeycomb configuration reduces weight by 78% while maintaining 3.2x greater compressive strength than aluminum alternatives.

Technical Superiority in Load-Bearing Applications

Third-party testing verifies that cíor mheala miotail structures withstand 42kN/m² axial loads, outperforming steel-reinforced concrete (28kN/m²) and carbon fiber composites (35kN/m²). Key metrics include:

| Parameter | Honeycomb | Steel | Aluminum |

|---|---|---|---|

| Weight (kg/m³) | 32 | 78 | 45 |

| Thermal Conductivity (W/mK) | 0.8 | 16.2 | 7.1 |

| Acoustic Damping (dB) | 26 | 9 | 14 |

Manufacturer Comparison Analysis

Leading suppliers demonstrate distinct capabilities in painéal meala miotail production:

| Vendor | Cell Density | Material Grade | Certifications |

|---|---|---|---|

| HexCore | 48 cells/inch² | AA6061-T6 | AS9100, ISO 14001 |

| AluHoney | 32 cells/inch² | AA5052-H32 | ISO 9001 |

| MetaPanel | 64 cells/inch² | Ti-6Al-4V | NADCAP, AS/EN 9100 |

Custom Engineering Solutions

Advanced fabrication techniques enable 15-stage customization of leathán miotail honeycomb products:

- Cell size optimization (2mm-25mm range)

- Surface treatment selection (Anodized/Ceramic/Polymer)

- Hybrid material layering (Al-Ti-Cu combinations)

Documented Performance Metrics

Industry applications validate cíor mheala miotail capabilities:

- 85% vibration reduction in aerospace assemblies

- 63% weight savings in marine bulkheads

- 41% improvement in thermal cycling resistance

Implementation Case Histories

The Sydney Metro project utilized 8,200m² of painéal meala miotail panels, achieving:

• 19-month reduction in construction timeline

• £2.3M saved in structural support systems

• 54dB noise attenuation for adjacent residential areas

Sustainable Future with Painéal Meala Miotail

Projections indicate 14.7% CAGR growth for leathán miotail honeycomb technologies through 2030, driven by renewable energy (34% sector demand) and electric vehicle adoption (27% market share). Ongoing R&D focuses on graphene-enhanced cíor mheala miotail variants with 89% recyclability rates.

(painéal meala miotail)

FAQS on painéal meala miotail

Q: What is a metal honeycomb panel (painéal meala miotail) used for?

A: Metal honeycomb panels are lightweight, high-strength structures used in aerospace, construction, and automotive industries for their durability and load-bearing capabilities.

Q: How does a metal honeycomb sheet (leathán miotail honeycomb) improve thermal insulation?

A: The hexagonal cell structure traps air, reducing heat transfer. This makes it ideal for applications like building facades and industrial insulation systems.

Q: What are the advantages of a metal honeycomb core (cíor mheala miotail)?

A: It offers exceptional stiffness-to-weight ratios, corrosion resistance, and vibration dampening, making it suitable for aircraft interiors and marine components.

Q: Can metal honeycomb panels be customized for specific projects?

A: Yes, they can be tailored in thickness, material (e.g., aluminum, titanium), and cell size to meet structural or design requirements for specialized applications.

Q: How do you maintain a metal honeycomb core structure?

A: Regular inspections for debris or corrosion, gentle cleaning with non-abrasive agents, and sealing exposed edges prevent degradation and ensure longevity.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025