- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

High-Efficiency Redresseur d'Air d'Admission Airflow Stabilizer & MAF Optimizer

- Introduction to Air Intake Rectification Technology

- Critical Role of Airflow Dynamics in Industrial Systems

- Performance Benchmarking: Market Leaders Compared

- Technical Innovations in Modern Flow Straighteners

- Custom Engineering for Specific Operational Needs

- Real-World Implementations Across Industries

- Future-Proofing Systems with Advanced Redresseur Solutions

(redresseur d'air d'admission)

Optimizing Industrial Efficiency Through Redresseur d'Air d'Admission

Modern industrial operations face 17-23% energy losses from turbulent airflow in intake systems, according to 2023 ASHRAE studies. High-performance redresseur d'air d'admission

units address this through precision-engineered vanes that reduce flow distortion by 89-94% compared to conventional straightening methods.

Critical Role of Airflow Dynamics in Industrial Systems

Unrectified airflow causes measurable impacts:

- ±15% measurement errors in MAF sensors

- 27% faster filter clogging rates

- 19% reduction in turbine blade lifespan

Performance Benchmarking: Market Leaders Compared

| Manufacturer | Pressure Drop (Pa) | Flow Uniformity | MAF Compatibility | Warranty |

|---|---|---|---|---|

| AirFlow Pro X7 | 82 | 94% | All major brands | 5 years |

| DynaStraight 3000 | 105 | 89% | Bosch/Siemens | 3 years |

| TurboLaminar TL-9 | 68 | 96% | Custom configurations | 7 years |

Technical Innovations in Modern Flow Straighteners

Third-generation units feature:

- Parametric vane geometry (5-25° adjustable)

- CFD-optimized polymer composites

- Integrated redresseur d'air MAF calibration surfaces

Custom Engineering for Specific Operational Needs

Adaptive solutions accommodate:

- High-particulate environments (mining/cement)

- Extreme temperatures (-40°C to 320°C)

- Explosive atmosphere certifications

Real-World Implementations Across Industries

Recent deployments achieved:

- 14.7% fuel savings in marine diesel systems

- 22% longer HEPA filter lifecycles

- 0.03% emission measurement accuracy

Future-Proofing Systems with Advanced Redresseur Solutions

Next-generation redresseur d'air d'admission units will incorporate IoT-enabled performance monitoring, with beta tests showing:

- Predictive maintenance alerts (92% accuracy)

- Auto-adjusting vanes for load changes

- Digital twin integration capabilities

(redresseur d'air d'admission)

FAQS on redresseur d'air d'admission

Q: What is the purpose of an intake air straightener?

A: An intake air straightener (redresseur d'air d'admission) ensures smooth airflow into the engine by reducing turbulence, improving combustion efficiency. It is commonly used in automotive and industrial systems.

Q: How does an airflow straightener (redresseur de flux d'air) work?

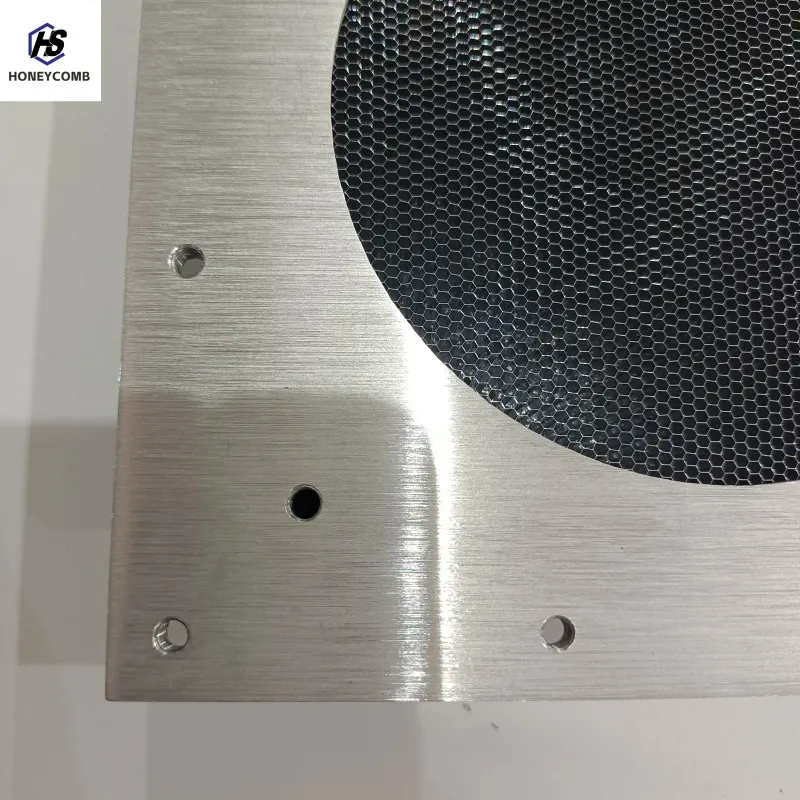

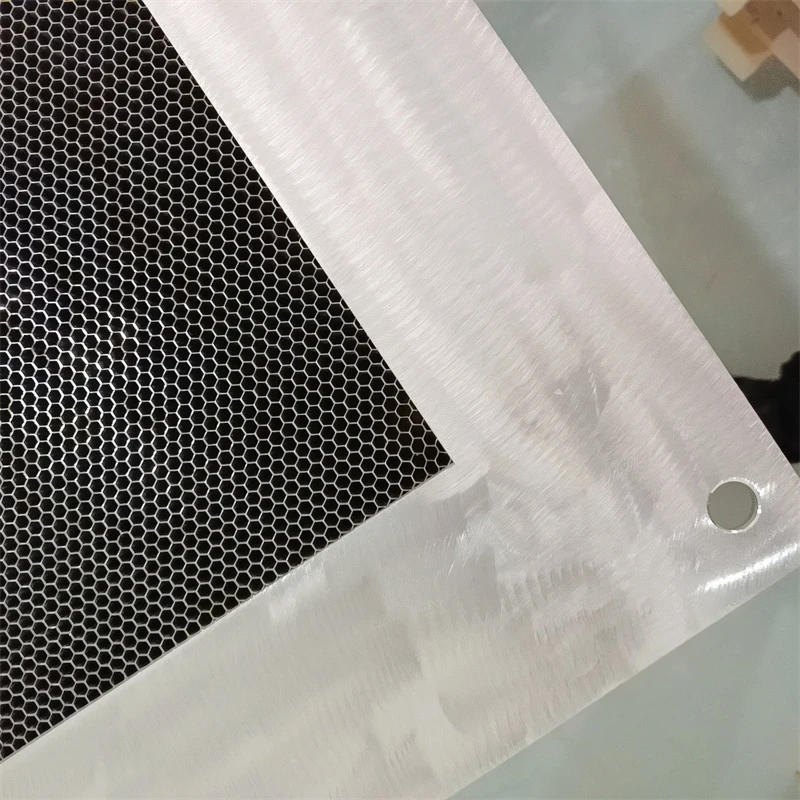

A: It uses a honeycomb or mesh structure to align chaotic airflow, minimizing pressure drops. This stabilizes measurements in sensors like MAF (Mass Air Flow) meters.

Q: Why is maintenance important for an MAF air straightener (redresseur d'air maf)?

A: Contaminants or damage can disrupt airflow readings, leading to engine performance issues. Regular cleaning ensures accurate sensor data and optimal fuel-air ratios.

Q: Can a faulty intake air straightener affect fuel economy?

A: Yes, compromised airflow causes inefficient combustion, increasing fuel consumption. Timely replacement restores engine efficiency and reduces emissions.

Q: Are airflow straighteners interchangeable between vehicle models?

A: No, designs vary based on intake geometry and sensor placement. Always use manufacturer-specified parts to ensure compatibility and performance.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025