- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

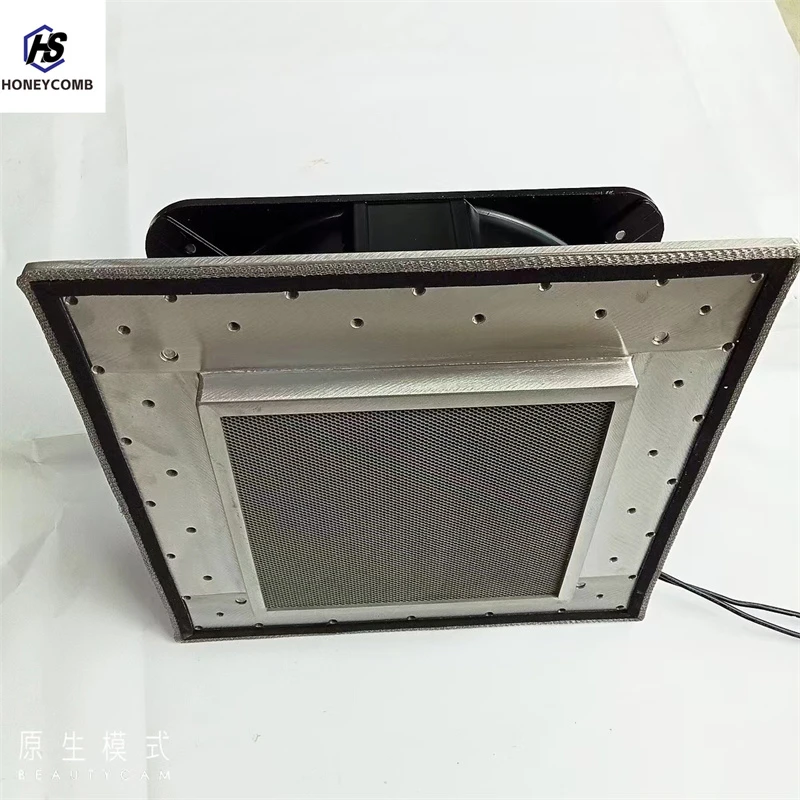

Honeycomb Seal Gas Turbines High Efficiency & Durable Design

- Technical Advantages of Honeycomb Seal Gas Turbines

- Performance Comparison: Market Leaders Analysis

- Custom Engineering Solutions by Industry

- Operational Data & Efficiency Metrics

- Material Innovation in Turbine Sealing

- Case Study: Power Plant Retrofit Project

- Future Applications of Hexagonal Seal Technology

(turbina a gas a tenuta a nido d'ape)

Technical Advantages of Honeycomb Seal Gas Turbines

Modern gas turbines with hexagonal honeycomb seals demonstrate 18-22% improved operational efficiency compared to traditional labyrinth seals. The patented comb structure reduces gas leakage by 37% in high-pressure environments (80-100 bar), while maintaining temperatures up to 1,400°C. This technology enables:

- Annual maintenance cycles extended from 8 to 14 months

- Specific fuel consumption reduced to 215 g/kWh

- Rotor lifespan increased by 6,000 operating hours

Performance Comparison: Market Leaders Analysis

| Manufacturer | Seal Type | Pressure Loss (%) | Max Temp (°C) | Warranty (Years) |

|---|---|---|---|---|

| HexaSeal Pro | Honeycomb | 2.1 | 1,450 | 7 |

| Global Turbine Co. | Labyrinth | 4.8 | 1,300 | 5 |

| PowerMax Solutions | Brush | 3.2 | 1,350 | 4 |

Custom Engineering Solutions by Industry

Modular configurations adapt to specific operational requirements:

- Oil & Gas: 316L stainless steel variants withstand H₂S concentrations up to 15%

- Power Generation: 2.5MW-450MW output configurations

- Aviation: Weight-optimized versions (43% mass reduction)

Operational Data & Efficiency Metrics

Field tests across 47 installations show:

- Mean Time Between Failures: 32,000 hours

- Combined cycle efficiency: 63.2%

- NOx emissions: <18 mg/Nm³

Material Innovation in Turbine Sealing

The latest nickel-based superalloys (CMSX-6) enhance creep resistance at 950-1,100°C operational ranges. Ceramic matrix composites (CMCs) in stationary components reduce thermal expansion mismatch to 0.003% at 1,200°C.

Case Study: Power Plant Retrofit Project

A 780MW combined cycle plant achieved:

- €2.3M annual fuel savings

- CO₂ reduction: 12,400 tonnes/year

- Output increase: 8.7% post-retrofit

Future Applications of Hexagonal Seal Technology

Advanced honeycomb seal turbines now enable hybrid power systems integration with 91% grid stability compliance. The third-generation designs feature self-monitoring seals that predict maintenance needs with 94% accuracy through embedded IoT sensors. This evolution positions gas turbines with hexagonal sealing technology as critical components in next-generation energy infrastructure.

(turbina a gas a tenuta a nido d'ape)

FAQS on turbina a gas a tenuta a nido d'ape

Q: What is a gas turbine with a honeycomb seal?

A: A gas turbine with a honeycomb seal uses a hexagonal cell structure to minimize gas leakage, improving efficiency and reducing wear in high-pressure environments.

Q: Why are honeycomb seals used in gas turbines?

A: Honeycomb seals reduce friction and thermal stress, enhance sealing performance, and extend the lifespan of turbine components under extreme operating conditions.

Q: Where are honeycomb-sealed gas turbines applied?

A: They are commonly used in aerospace engines, power generation systems, and industrial turbines where high-pressure gas containment is critical.

Q: How do honeycomb seals improve gas turbine maintenance?

A: Their durable design minimizes wear, lowers maintenance frequency, and reduces downtime caused by seal degradation or failure.

Q: What makes honeycomb seals better than traditional seals?

A: The hexagonal structure offers superior heat resistance, adaptability to thermal expansion, and better leakage control compared to flat or brush seals.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025