- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Multi domain applications of Honeycomb Air Flow Straightener

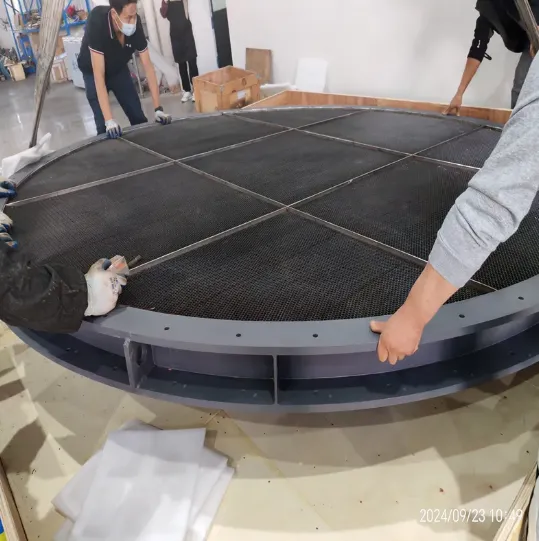

Honeycomb Air Flow Straightener, As a simple yet powerful device, it has demonstrated its unique value in many fields. It imitates the hexagonal structure of a honeycomb to comb through turbulent airflow, thereby achieving uniformity and stability of the airflow. This technology is widely used in situations that require precise airflow control, significantly improving the performance and accuracy of related equipment.

Honeycomb Air Flow Straightener is widely used in wind tunnel testing in the aerospace industry

Wind tunnel testing is an important means of studying the aerodynamic characteristics of aircraft, which requires creating a stable and uniform airflow environment. Air flow straightener can effectively eliminate airflow turbulence in wind tunnels, ensuring the accuracy and reliability of experimental data. In addition, in the design of aircraft engine intake ducts, honeycomb structures can also optimize the way airflow enters the engine, improving engine efficiency and thrust.

In the field of environmental monitoring, Honeycomb Air Flow Straightener is used to improve the accuracy of air sampling equipment

Accurate air sampling is crucial for assessing air quality. By installing the maf straightener, it can be ensured that the sampling equipment can uniformly suck in air, avoiding sampling errors caused by turbulent airflow. This is of great significance for monitoring pollutant concentrations and analyzing air composition, which helps to scientifically formulate environmental protection policies.

The medical field also benefits from the application of Honeycomb Air Flow Straightener

Uniform and stable airflow is crucial for the respiratory safety of patients in ventilators and anesthesia machines. The honeycomb structure can ensure that gas enters the patient's lungs evenly, reduce the risk of respiratory distress, and improve treatment effectiveness. In addition, in places with extremely high air quality requirements such as clean rooms and operating rooms, Honeycomb airfow straightener can effectively control the direction and speed of airflow, reduce the spread of pollutants, and provide patients with a safe and clean medical environment

In addition to the aforementioned fields, Honeycomb Air Flow Straightener has a wide range of applications in the automotive industry, electronic cooling, building ventilation, and other areas.

For example, in the cooling system of a car engine, it can improve air circulation and enhance heat dissipation efficiency. In electronic device cooling systems, it can guide airflow evenly through the heat sink, reducing chip temperature. In building ventilation systems, it can optimize air distribution and improve indoor air quality.

In summary, Honeycomb Air Flow Straightener plays an important role in many fields such as aerospace, environmental monitoring, and healthcare due to its simple structure, powerful functionality, and strong adaptability. With the continuous development of technology, its application scope will further expand, bringing higher efficiency and more precise control to various industries. In the future, further research and optimization of honeycomb structure design, as well as the development of new materials, will help to further enhance the performance of maf air fow ուղղիչ and enable them to play a greater value in more fields.

Honeycomb Air Flow Straightener FAQs

What is Honeycomb Air Flow Straightener?

Honeycomb Air Flow Straightener is a device composed of densely arranged hexagonal (or circular/rectangular) small pipes, installed at the entrance of wind tunnels, piping systems, or fluid equipment to improve airflow quality. Its main functions are:

Eliminate large-scale turbulence and eddies

Make the airflow distribution more uniform

Correct the direction of airflow and reduce deviation

Why do cellular rectifiers usually use hexagonal structures?

The hexagonal honeycomb structure has the following advantages:

Higher structural strength (compared to circular or rectangular)

More uniform airflow distribution (less airflow interference between adjacent units)

Better turbulence suppression effect (more stable boundary layer development)

Higher porosity (reducing pressure drop)

How to choose the key parameters of cellular rectifier?

The following parameters are mainly considered:

Unit size (usually 310mm in diameter, the smaller the rectification effect, the better but the greater the voltage drop)

Length to diameter ratio (L/D) (length to diameter ratio, generally 6:1~10:1)

Material (aluminum, stainless steel or composite material, selected according to temperature/corrosion resistance requirements)

Porosity (affecting airflow resistance and pressure drop)

What are the important applications of cellular rectifiers in?

The main application scenarios include:

Wind tunnel testing (improving airflow quality)

HVAC system (improving ventilation uniformity)

Automotive industry (optimizing intake system)

Aerospace (Engine Testing)

Industrial processes (manufacturing equipment that requires stable airflow)

How to maintain Honeycomb Air Flow Straightener?

Maintenance points:

Regular cleaning (to prevent dust/particles from clogging honeycomb holes)

Check for structural deformation (ensure complete geometric shape of honeycomb units)

Monitor pressure drop changes (abnormal pressure drop may indicate blockage or damage)

Corrosion protection (especially for metal materials in humid environments)

Ապրանքների կատեգորիաներ

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsՆորություններJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionՆորություններJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsՆորություններJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionՆորություններJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsՆորություններJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsՆորություններJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlՆորություններJul.11,2025