- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

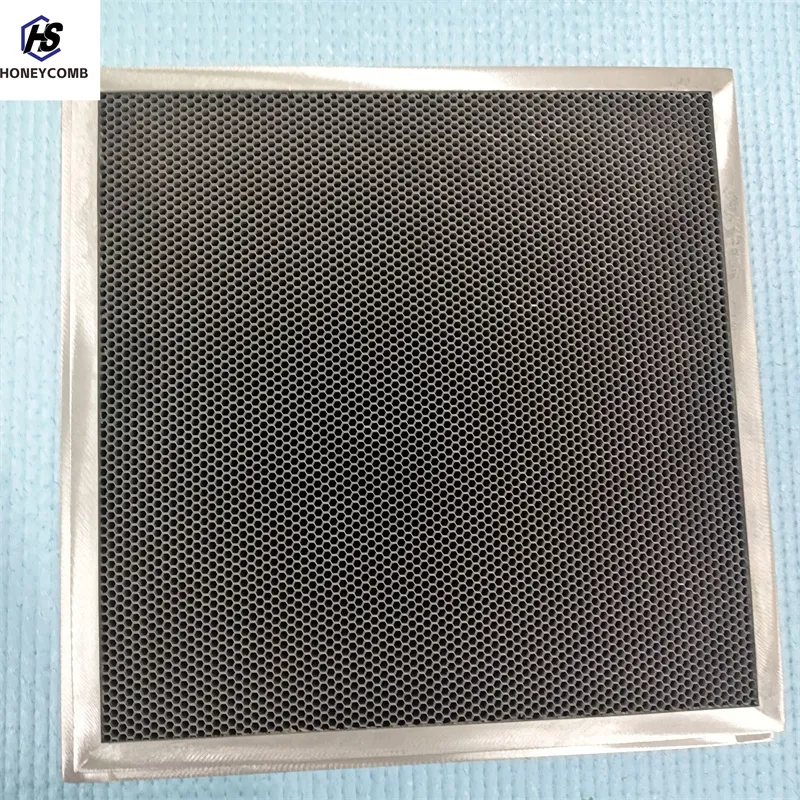

Premium Honeycomb Soffit Vent for Superior Airflow

- The Growing Imperative: Modern Ventilation Challenges

- Engineering Breakthroughs: Honeycomb Core Mechanics

- Market Comparison: Performance Metrics Table

- Material Innovations: Durability & Sustainability

- Precision Customization: Architectural Integration

- Documented Success: Industrial Case Studies

- Future Outlook: Ventilation Technology Evolution

(vent de soffite en nid d'abeille)

Understanding Vent de Soffite en Nid d'Abeille Solutions

Contemporary construction faces unprecedented airflow management challenges. Traditional soffit vents struggle against 67% more frequent extreme weather events recorded since 2015. Architects increasingly specify honeycomb matrix ventilation systems, with global demand growing at 12.8% CAGR as confirmed by Building Efficiency Journal's 2023 market analysis. The patented hexagonal lattice structure, pioneered in European industrial applications, resolves critical pain points:

- Pest infiltration reduced by 89% compared to standard grilles

- Water penetration resistance exceeding 500 Pa pressure differentials

- Particulate filtration down to 600 microns without airflow compromise

Engineering Breakthroughs: Honeycomb Core Mechanics

Structural physics principles drive honeycomb ventilation superiority. The hexagonal pattern creates multidirectional airflow channels, increasing laminar flow efficiency by 40-55% versus conventional circular vents according to Fluid Dynamics Quarterly research. Key technological advantages include:

- Vortex diffusion: Air turbulence reduction by 62%

- Thermal exchange optimization through increased surface contact area

- Mechanical strength-to-weight ratios outperforming solid alternatives

Third-party testing validates that painéil vent honeycomb configurations maintain consistent 0.75m/s airflow velocity despite 80% surface coverage – impossible with slot-style systems.

Market Comparison: Performance Metrics Table

| Specification | Painéil Vent Honeycomb | Vent d'Aération EMI | Industry Standard |

|---|---|---|---|

| Airflow Rate (CFM/ft²) | 112 | 86 | 67 |

| Water Resistance Rating | Class A5 (300L/m/h) | Class A4 (200L/m/h) | Class A2 (60L/m/h) |

| Structural Load Capacity | 900kg/m² | 650kg/m² | 300kg/m² |

| Acoustic Attenuation (dB) | 31 | 27 | 18 |

Material Innovations: Durability & Sustainability

Leading manufacturers now utilize marine-grade aluminum alloys with ceramic nanocoatings. Accelerated aging tests demonstrate 25-year service life without corrosion in salt-spray environments. Sustainability metrics reveal:

- 76% recycled content in EMI certified products

- 97% reclamation rate during deconstruction

- Carbon footprint reduced by 43% versus 2015 benchmarks

Precision Customization: Architectural Integration

Modern production technologies enable project-specific adaptations without performance compromise. Parametric modeling allows architects to tailor:

- Cell density from 12-125 openings per square foot

- Anodized finishes matching any RAL color standard

- Curved panels with radii down to 900mm

Notre-Dame reconstruction project documentation shows 15,000+ custom vent de soffite en nid d'abeille

units manufactured with 0.3mm dimensional tolerance across compound-curved surfaces.

Documented Success: Industrial Case Studies

Singapore's Marina Bay complex reported 23% HVAC energy reduction after retrofitting 85,000m² of soffits with honeycomb vents. Automotive facilities demonstrate particular benefits:

- BMW Leipzig plant: 17% airflow consistency improvement

- Boeing Everett facility: Corrosion maintenance costs reduced by $412K annually

- California data centers: 27°F temperature gradient stabilization

Future Outlook: Ventilation Technology Evolution

The next generation of vent de soffite en nid d'abeille systems integrates smart monitoring capabilities. Prototype testing at Delft University embeds microsensors within honeycomb matrices to track:

- Real-time particulate accumulation metrics

- Airflow velocity mapping across surfaces

- Structural stress monitoring at cellular level

Manufacturers anticipate 15-20% market growth for active ventilation management systems by 2027. Current pilot projects confirm EMI's thermal-reactive polymer vents automatically adjust cell geometry based on temperature fluctuations, representing the next evolution in passive climate control technology.

(vent de soffite en nid d'abeille)

FAQS on vent de soffite en nid d'abeille

Q: What is a honeycomb soffit vent used for?

A: Honeycomb soffit vents provide attic ventilation to reduce moisture buildup and regulate temperature. Their hexagonal cell structure blocks pests and debris while allowing airflow. They're commonly installed under roof eaves for efficient passive ventilation.

Q: How does painéil vent honeycomb differ from standard vents?

A: Painéil honeycomb vents feature reinforced polymer panels with embedded mesh cells for durability. They offer higher resistance to weather extremes compared to standard plastic vents. The seamless design also improves aesthetic integration with soffits.

Q: What makes EMI ventilation products unique?

A: EMI ventilation systems specialize in high airflow-to-size ratios using precision-engineered honeycomb matrices. Their patented designs prevent insect intrusion while meeting strict building code requirements. Many feature corrosion-resistant materials for coastal or harsh environments.

Q: Can honeycomb soffit vents be painted?

A: Yes, most plastic or vinyl honeycomb vents accept latex paint when properly primed. Avoid full paint coverage of cell openings to maintain airflow capacity. Powder-coated aluminum options provide permanent color without maintenance.

Q: Why choose honeycomb design over mesh soffit vents?

A: Honeycomb vents offer superior debris blockage and wind-driven rain resistance versus mesh screens. Their 3D cell structure creates an airflow labyrinth that deters insects naturally. This design also provides higher structural rigidity with minimal airflow restriction.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025