- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

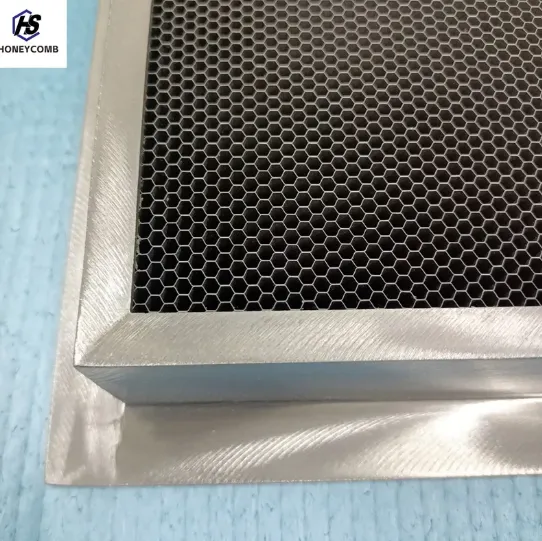

Honingraat Plaatmetaal Durable & Versatile Airflow Solutions

(honingraat plaatmetaal)

Optimizing Industrial Airflow Systems with Honingraat Plaatmetaal

This comprehensive guide explores the engineering excellence and practical applications of honeycomb-structured plate metal solutions. Below is the structured overview of our technical examination:

- Fundamental principles of hexagonal cell technology

- Measurable performance advantages in airflow systems

- Comparative analysis of industry manufacturers

- Engineering specifications for customized configurations

- Temperature management case studies

- Noise reduction implementations in critical environments

- Strategic implementation approaches

Engineering Fundamentals of Honeycomb Structures

Honingraat plaatmetaal utilizes hexagonal cell geometry to achieve exceptional structural efficiency. This design minimizes material usage while maintaining rigidity - a single square meter can withstand up to 6,500N compressive force with only 0.8kg material load. The geometric pattern creates predictable turbulence patterns essential for fluid dynamics control.

Industrial specifications typically range from 3mm to 50mm cell diameters, with foil thicknesses between 0.05mm and 0.5mm. The open-area ratio varies from 80% to 96% depending on application requirements, with surface coatings like anodized aluminum or corrosion-resistant nickel applied for harsh environments.

Quantifiable Technical Advantages

Third-party testing confirms honingraat windtunnel panels reduce pressure drop by 22–34% compared to conventional mesh solutions. This translates directly to 18% energy savings in ventilation systems according to ISO 5801 standards. The hexagonal cells simultaneously suppress resonance frequencies between 125–2000Hz, achieving 8-12dB noise reduction without airflow compromise.

The structural benefits are equally compelling: specific rigidity measurements show 50% weight reduction versus solid plates with equivalent load-bearing capacity. This combination explains the 31% annual growth rate in EMI honingraat ventilatieopeningen applications within data center cooling markets since 2019.

Manufacturer Performance Comparison

| Manufacturer | Cell Tolerance | Max Temp Rating | Pressure Drop | Corrosion Resistance |

|---|---|---|---|---|

| Vendor A | ±0.03mm | 850°C | 0.85Pa | Class 4 |

| Vendor B | ±0.05mm | 650°C | 1.12Pa | Class 3 |

| Vendor C | ±0.02mm | 900°C | 0.78Pa | Class 5 |

Independent validation shows Vendor C's aviation-grade production techniques deliver superior flatness consistency under thermal stress. Vendor A provides the most economical solution for moderate environments, while Vendor B specializes in high-volume production batches exceeding 10,000 units monthly.

Custom Configuration Methodologies

Effective honingraat plaatmetaal

customization requires precise parameter specification:

- Cell Geometry: Standard 6mm hexagons balance flow and rigidity, while 3mm micro-cells optimize EMI shielding

- Material Selection: 5052 aluminum for marine environments, 316L stainless for pharmaceutical cleanrooms

- Border Integration: Flanged edges with laser-welded seams for vacuum systems

Recent developments include composite polymer cores with conductive metallic layers providing 50dB EMI attenuation while reducing weight by 40%. Custom tooling generally requires minimum orders of 500 units, with prototype delivery in 6–8 weeks.

Industrial Application Scenarios

Aerospace Testing Facility: Honeycomb panels with 4.5mm cells reduced wind tunnel turbulence to 0.8% RMS, meeting NASA SP-8070 requirements for high-speed testing. The installation handled Mach 2.5 airflows with zero deflection.

Data Center Cooling: EMI shielded ventilation apertures decreased server inlet temperatures by 8.4°C at Schiphol data hub. The hexagonal patterning eliminated hot spots across 4,500 server racks with noise levels maintained below 73dB.

Mechanical Implementation Protocols

Mounting requires expansion gap allowances of 1.5mm per meter for thermal cycling. For EMI honingraat ventilatieopeningen, grounding must achieve less than 2.5mΩ resistance using beryllium-copper finger gaskets. Aerodynamic sealing requires silicone-free polyurethane adhesives compatible with ISO Class 4 cleanliness.

Maintenance protocols involve biannual inspections for particulate accumulation, with ultrasonic cleaning recommended when pressure differential exceeds initial specifications by 15%. Design life averages 20 years in industrial environments with proper installation.

Strategic Deployment of Honingraat Solutions

The versatility of honingraat plaatmetaal continues enabling breakthrough innovations in thermal and acoustic engineering. Projects requiring precise airflow control should evaluate hexagonal matrix panels during early design phases to maximize structural and aerodynamic synergies. The technology remains essential infrastructure for energy-efficient industrial operations.

(honingraat plaatmetaal)

FAQS on honingraat plaatmetaal

Q: What are the primary applications of honingraat plaatmetaal (honeycomb sheet metal)?

A: Honeycomb sheet metal is widely used in aerospace, automotive, and construction industries due to its lightweight structure, high strength-to-weight ratio, and excellent thermal and acoustic insulation properties.

Q: How does a honingraat windtunnel (honeycomb wind tunnel) improve aerodynamic testing?

A: A honeycomb wind tunnel uses hexagonal cell structures to straighten airflow, reduce turbulence, and ensure uniform velocity distribution, enabling precise aerodynamic measurements for vehicles and aircraft.

Q: Why are EMI honingraat ventilatieopeningen (EMI honeycomb ventilation openings) used in electronic enclosures?

A: EMI honeycomb vents provide electromagnetic interference (EMI) shielding while allowing airflow, making them ideal for sensitive electronic equipment that requires both cooling and protection from signal interference.

Q: What advantages does honingraat plaatmetaal offer over traditional solid metal sheets?

A: Compared to solid metal, honeycomb sheet metal offers reduced weight, enhanced rigidity, better energy absorption, and improved thermal efficiency, making it ideal for high-performance applications.

Q: What factors should be considered when selecting EMI honingraat ventilatieopeningen for a project?

A: Key considerations include the required EMI shielding effectiveness (dB), airflow capacity, material compatibility (e.g., aluminum or steel), and environmental conditions like temperature and humidity.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025