- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Advanced Shielding Solutions with Stainless Steel Honeycomb Structures

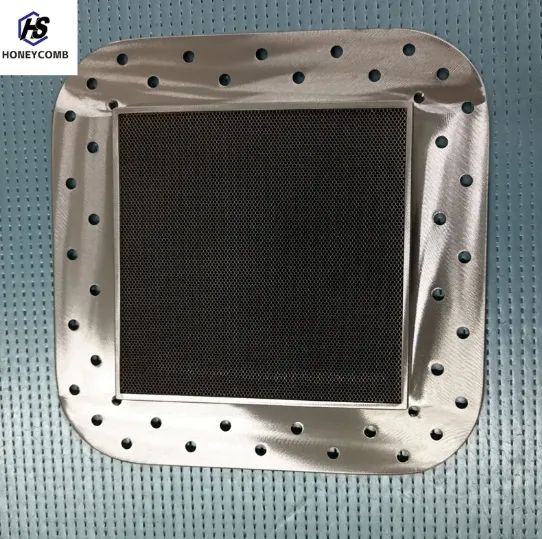

IL honeycomb waveguide has become an essential component in environments requiring high-performance electromagnetic shielding. By integrating the principles of waveguide cutoff and honeycomb geometry, this structure effectively blocks unwanted electromagnetic interference (EMI) while permitting the free flow of air. Commonly fabricated from conductive metals such as stainless steel or aluminum, the waveguide offers a unique solution for EMI-sensitive applications, including military shelters, telecom enclosures, and cleanrooms.

What distinguishes the honeycomb waveguide is its ability to function as a ventilation and shielding device simultaneously. Each honeycomb cell acts as a miniature waveguide below cutoff, stopping electromagnetic waves beyond a certain frequency while maintaining air circulation. With modern manufacturing processes such as high-temperature vacuum brazing, these waveguides achieve outstanding mechanical stability and long-term durability in demanding environments.

Stainless Steel Honeycomb for High-Performance Industrial Shielding

As EMI shielding requirements become increasingly stringent, nido d'ape in acciaio inox has emerged as a preferred material for both structural and electronic applications. Its corrosion resistance, mechanical strength, and conductive properties make it ideal for shielding cabinets, enclosures, and EMI vents across multiple industries. Additionally, its honeycomb structure provides a large surface area with low weight, which enhances both thermal dissipation and airflow.

Manufacturers now deploy high-precision fabrication methods such as automatic laser spot welding and vacuum brazing to ensure the integrity of nido d'ape in acciaio inox products. These advanced techniques not only boost conductivity and EMI attenuation performance but also increase product consistency and reduce failure risks. The result is a shielding solution that is both highly effective and reliable in mission-critical applications such as aerospace instrumentation, defense electronics, and medical imaging systems.

Stainless Honeycomb as the Core of Lightweight Shielding Panels

The demand for lighter yet more effective EMI shielding materials has brought nido d'ape inossidabile to the forefront of material engineering. Compared to solid metal sheets, stainless honeycomb provides superior rigidity-to-weight ratios, allowing enclosures and barriers to meet EMI regulations without adding unnecessary mass. This is especially valuable in aviation and automotive sectors, where weight savings directly impact performance and fuel efficiency.

In many cases, nido d'ape inossidabile is sandwiched between metal skins or embedded into shielding panels. The unique geometry channels electromagnetic waves through narrow paths, effectively attenuating them while preserving ventilation and structural function. This makes the material suitable for EMI vents, electronic equipment housings, and any application requiring lightweight shielding without compromising on protection.

Steel Honeycomb Enhancing Structural and Electrical Shielding

In situations where additional mechanical strength is needed, nido d'ape in acciaio proves to be a practical alternative. It combines the robustness of carbon or alloy steel with the functional design of honeycomb architecture. While slightly heavier than stainless variants, nido d'ape in acciaio offers superior rigidity and impact resistance, making it ideal for load-bearing shielding structures or environments exposed to mechanical stress.

Steel’s magnetic and conductive properties also make it highly suitable for specific EMI/RF shielding applications, especially where high attenuation and structural durability are required. Whether used in defense bunkers, test facilities, or power substations, nido d'ape in acciaio contributes to both the physical resilience and electromagnetic integrity of the infrastructure.

EMI Vents Designed for Modern Shielding Challenges

EMI vents are a crucial component in maintaining both airflow and shielding effectiveness within sensitive electronic enclosures. These vents, typically composed of metal honeycomb cores, are strategically designed to allow air or gas to pass through while filtering out EMI across a broad frequency range. Modern prese d'aria emi are optimized using state-of-the-art materials and manufacturing techniques, including laser welding and vacuum brazing, to ensure long-lasting performance in hostile environments.

As industries demand smaller, lighter, and more efficient electronics, prese d'aria emi must meet evolving size, airflow, and shielding specifications. Customization options—such as different cell sizes, plating materials (e.g., nickel, tin, or silver), and mounting configurations—allow these vents to be adapted to virtually any enclosure type. Whether integrated into aerospace avionics, medical scanners, or telecom cabinets, these vents ensure equipment remains cool and interference-free.

EMI vents FAQs

What makes a honeycomb waveguide effective for EMI shielding?

IL honeycomb waveguide uses its cellular geometry to restrict the passage of electromagnetic waves beyond a certain frequency while permitting airflow. When combined with conductive metals and precise cell sizing, it provides high EMI attenuation performance without compromising ventilation.

Why is stainless steel honeycomb ideal for harsh environments?

Stainless steel honeycomb offers exceptional corrosion resistance, mechanical strength, and thermal durability. These characteristics make it suitable for shielding applications in environments with high humidity, temperature extremes, or chemical exposure, such as aerospace or marine systems.

How is stainless honeycomb used in lightweight shielding panels?

Stainless honeycomb acts as the lightweight core in EMI shielding panels, allowing designers to achieve high strength and electromagnetic attenuation with minimal weight. It is especially useful in mobile platforms like aircraft or electric vehicles where every kilogram matters.

What are the benefits of using steel honeycomb in structural shielding?

Nido d'ape in acciaio provides enhanced mechanical strength and stiffness while maintaining EMI shielding capabilities. It is particularly suited for applications where impact resistance and load-bearing capacity are critical, such as industrial enclosures or transport containers.

How do emi vents improve performance in electronic systems?

EMI vents regulate internal temperatures while shielding sensitive electronics from external electromagnetic interference. Their honeycomb structure allows consistent airflow and EMI protection, making them essential for high-density or mission-critical electronic enclosures.

Categorie di prodotti

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNotiziaJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNotiziaJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNotiziaJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNotiziaJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNotiziaJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNotiziaJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNotiziaJul.11,2025