- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Gen . 09, 2025 10:48

Back to list

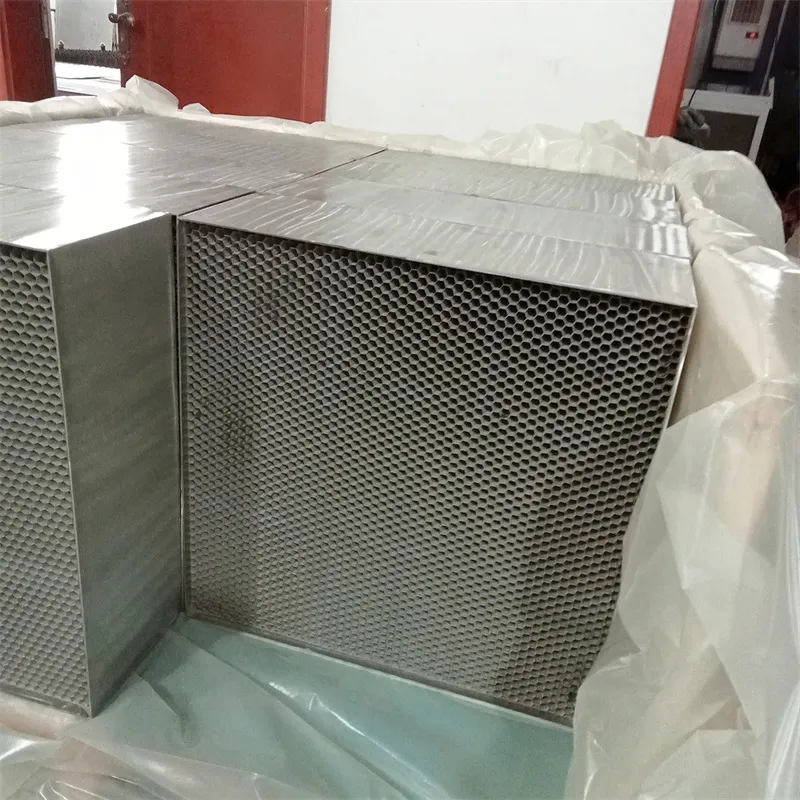

maf honeycomb screen

Cell aluminium honeycomb technology stands at the forefront of modern engineering innovations, offering a unique combination of lightweight structure and high strength. This advanced material is seen as a game-changer across various industries, especially in automotive, aerospace, and construction sectors, where reducing weight while maintaining structural integrity is crucial.

Trust in Innovation With a track record of reliability, cell aluminium honeycomb structures are trusted in various critical applications. Their use in protective equipment and structures has only increased trust in their performance, as they provide superior energy absorption in impact scenarios, protecting both lives and equipment. Moreover, their corrosion-resistant nature means that they offer longevity, which is a crucial factor for industries looking to invest in sustainable and low-maintenance materials. Future-Proof Material As industries strive toward sustainability, cell aluminium honeycomb emerges as an eco-friendly solution that contributes to material efficiency and energy savings. Due to its recyclability, firms opting for this material can align themselves with global sustainability goals without sacrificing performance or profitability. Implementing cell aluminium honeycomb solutions is not just about selecting a material; it is about transforming the potential of products across various sectors. It epitomizes the balance between innovation and practicality, providing a blueprint for future advancements. Businesses that incorporate this technology stand to benefit not only from improved product performance but also from contributing to a sustainable future. As research and development in this area continue to evolve, cell aluminium honeycomb is positioned to lead the next wave of cutting-edge engineered solutions, cementing its place as an indispensable asset in modern industrial applications.

Trust in Innovation With a track record of reliability, cell aluminium honeycomb structures are trusted in various critical applications. Their use in protective equipment and structures has only increased trust in their performance, as they provide superior energy absorption in impact scenarios, protecting both lives and equipment. Moreover, their corrosion-resistant nature means that they offer longevity, which is a crucial factor for industries looking to invest in sustainable and low-maintenance materials. Future-Proof Material As industries strive toward sustainability, cell aluminium honeycomb emerges as an eco-friendly solution that contributes to material efficiency and energy savings. Due to its recyclability, firms opting for this material can align themselves with global sustainability goals without sacrificing performance or profitability. Implementing cell aluminium honeycomb solutions is not just about selecting a material; it is about transforming the potential of products across various sectors. It epitomizes the balance between innovation and practicality, providing a blueprint for future advancements. Businesses that incorporate this technology stand to benefit not only from improved product performance but also from contributing to a sustainable future. As research and development in this area continue to evolve, cell aluminium honeycomb is positioned to lead the next wave of cutting-edge engineered solutions, cementing its place as an indispensable asset in modern industrial applications.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025