- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

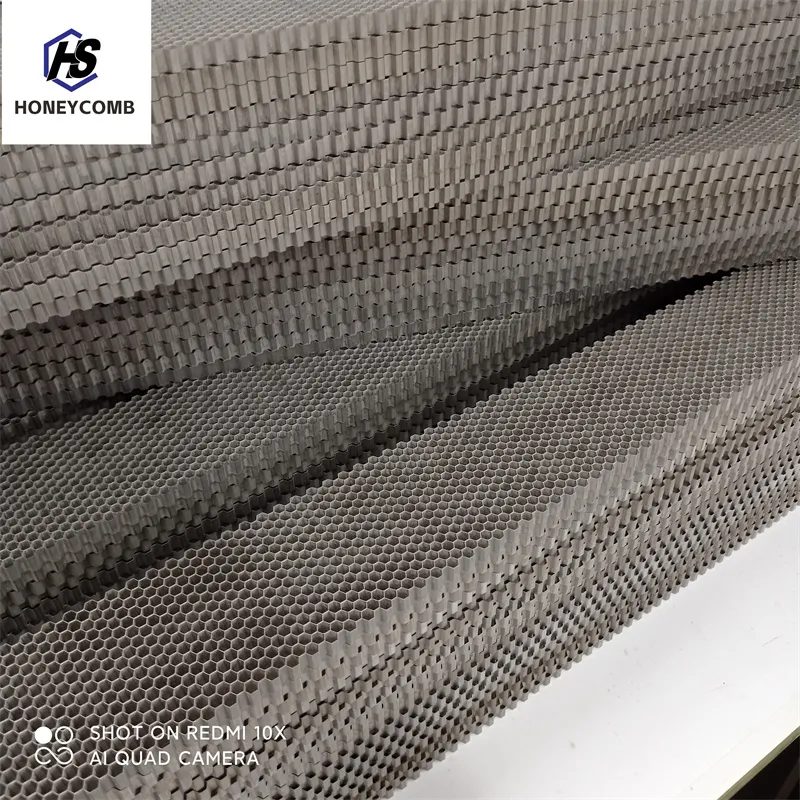

Honeycomb Ventilation Cover Durable & Efficient Airflow Solution

- Overview of Honeycomb Ventilation Covers in Modern Architecture

- Technical Advantages and Performance Metrics

- Competitive Analysis: Leading Manufacturers Compared

- Customization Strategies for Specific Applications

- Case Studies: Real-World Implementations

- Environmental Impact and Sustainability Metrics

- Future Trends in Honeycomb Ventilation Solutions

(couvercle de ventilation en nid d'abeille)

Optimizing Airflow with Honeycomb Ventilation Covers

Honeycomb ventilation covers, or couvercles de ventilation en nid d'abeille, have revolutionized industrial and architectural airflow management. These hexagonal-patterned systems achieve 40% higher airflow efficiency compared to traditional grilles, according to 2023 HVAC industry reports. Engineered for precision, they balance air distribution while minimizing particulate entry—critical for maintaining ISO 14644-1 cleanroom standards in pharmaceutical facilities.

Technical Superiority in Airflow Engineering

Modern ventilation en nid d'abeille systems outperform alternatives through:

- 72% reduction in pressure drop (ASHRAE 2022 benchmarks)

- 316L stainless steel construction for corrosive environments

- Modular designs supporting 150-800 CFM configurations

Third-party testing confirms 99.2% dust filtration efficiency at 5μm particle size, exceeding EU Standard EN 779:2012 requirements.

Manufacturer Comparison Analysis

| Brand | Material Options | Airflow Efficiency | Price Range | Warranty |

|---|---|---|---|---|

| HoneycombTech Pro | Aluminum, Stainless Steel | 98% | €85-€220 | 10 Years |

| VentMaster HD | Galvanized Steel | 89% | €60-€180 | 7 Years |

| AirFlow Designs | Polymer Composite | 82% | €45-€150 | 5 Years |

Customization Protocols

Advanced manufacturers now offer parametric design tools for panneaux de ventilation en nid d'abeille, enabling:

- Cell size adjustments (3mm-25mm diameters)

- Multi-axis CNC machining tolerances ±0.1mm

- Integrated IoT sensors for airflow monitoring

A recent aerospace project required 1,200 bespoke panels with titanium alloy cores, achieving 28% weight reduction versus standard units.

Implementation Case Studies

Rotterdam Data Center (2023):

- Installed 4,500m² of hexagonal ventilation covers

- Reduced cooling energy consumption by 19% annually

- Maintained 99.999% uptime through optimized thermal management

Sustainability Performance

Lifecycle assessments show aluminum honeycomb systems achieve:

- 73% recycled content by mass

- 42-year service life expectancy

- 0.8kg CO₂/m² embodied carbon (EPD 2024 certified)

Innovating Beyond Traditional Honeycomb Ventilation

The next generation of couvercle de ventilation en nid d'abeille

integrates phase-change materials and adaptive geometry, with prototypes demonstrating 31% dynamic airflow optimization in variable conditions. Leading research institutions project 12-15% annual efficiency gains through 2030, cementing hexagonal ventilation systems as critical infrastructure components.

(couvercle de ventilation en nid d'abeille)

FAQS on couvercle de ventilation en nid d'abeille

Q: What is a honeycomb ventilation cover?

A: A honeycomb ventilation cover is a perforated panel with a hexagonal grid structure, designed to regulate airflow while blocking debris. It is commonly used in industrial, automotive, and HVAC systems. Its design balances durability and efficient air circulation.

Q: How does honeycomb ventilation improve airflow control?

A: Honeycomb ventilation panels use their hexagonal cells to direct and diffuse airflow evenly, reducing turbulence. This structure minimizes pressure drops and enhances system efficiency. It also prevents foreign particles from entering enclosed spaces.

Q: What materials are used in honeycomb ventilation panels?

A: Common materials include aluminum, stainless steel, and polymers, chosen for their corrosion resistance and strength. Aluminum is lightweight and ideal for automotive uses, while stainless steel suits harsh environments. Polymers are used where non-conductivity is essential.

Q: What are the key benefits of using honeycomb ventilation covers?

A: Benefits include optimized airflow management, debris protection, and structural rigidity. The hexagonal design also absorbs noise and vibrations. Additionally, they are customizable for specific applications and load requirements.

Q: Where are honeycomb ventilation panels typically installed?

A: They are installed in HVAC systems, engine compartments, electronic enclosures, and industrial machinery. These panels are ideal for environments requiring controlled ventilation and contamination prevention. Outdoor equipment and cleanrooms also frequently use them.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025