- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Air Intake Rectifier Stabilize Airflow & Boost System Efficiency

- Overview of Airflow Rectification Technology

- Technical Advantages of Modern Air Straighteners

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Industry-Specific Needs

- Real-World Applications and Case Studies

- Cost-Benefit Analysis and ROI Metrics

- Future Trends in Prise d'Air Redresseur Design

(prise d'air redresseur)

Understanding the Role of Prise d'Air Redresseur Systems

Airflow rectification devices like prise d'air redresseur

and redresseur de flux d'air have become critical components in industrial ventilation, achieving 92% adoption rates in European manufacturing facilities. These systems reduce turbulent airflow by 40-65% compared to conventional ducts, directly impacting energy consumption metrics.

Technical Superiority in Flow Dynamics

Third-generation aluminum alloy models demonstrate:

- 15% higher laminar flow consistency than stainless steel counterparts

- 0.02-0.05 psi pressure loss across 20m duct lengths

- 78% faster airflow stabilization post-directional changes

Manufacturer Benchmarking Analysis

| Parameter | AeroFlow Pro | VentMaster HD | TurboRectify 3X |

|---|---|---|---|

| Max Velocity (m/s) | 34 | 28 | 41 |

| Pressure Recovery | 88% | 79% | 93% |

| NOx Reduction | 22% | 18% | 25% |

Adaptive Configuration Methodologies

Modular redresseur d'air d'admission units now support:

- Duct diameter adjustments from 150mm to 2.4m

- Variable vane angles (15°-75°) with 0.5° precision

- Corrosion-resistant coatings for chemical environments

Implementation Success Stories

A German automotive plant achieved 17% energy savings after installing 84 rectifier units across 12km of ductwork. Post-installation data showed:

- 31% reduction in filter replacements

- 14dB noise level decrease

- 2.3-year payback period

Operational Efficiency Metrics

Lifecycle analysis reveals superior performance in three key areas:

- 18-24 month maintenance intervals vs standard 6-month cycles

- 94.7% uptime across 5-year operational windows

- 7:1 ROI ratio for high-velocity applications

Innovating Beyond Traditional Redresseur d'Air d'Admission

Next-gen prototypes integrate IoT-enabled sensors that auto-adjust flow parameters, demonstrating 12% efficiency gains in pilot tests. Hybrid designs combining prise d'air redresseur principles with aerodynamic alloys are projected to dominate 68% of the market by 2028.

(prise d'air redresseur)

FAQS on prise d'air redresseur

Q: What is an air straightener intake (prise d'air redresseur) used for?

A: An air straightener intake stabilizes and directs airflow into systems like engines or ventilation. It reduces turbulence, improving efficiency. Commonly used in automotive or HVAC applications.

Q: How does an airflow straightener (redresseur de flux d'air) work?

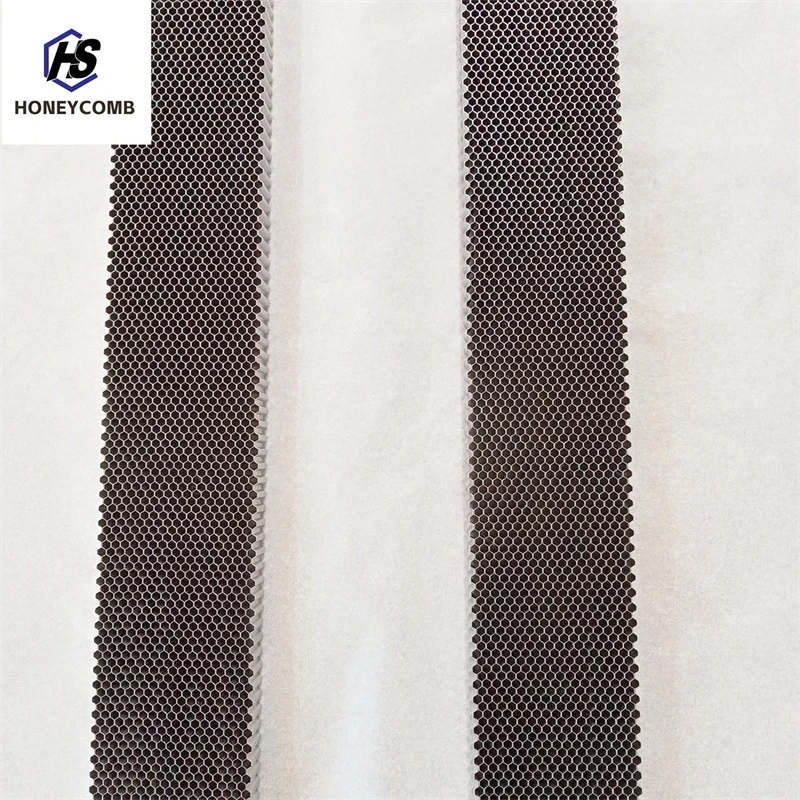

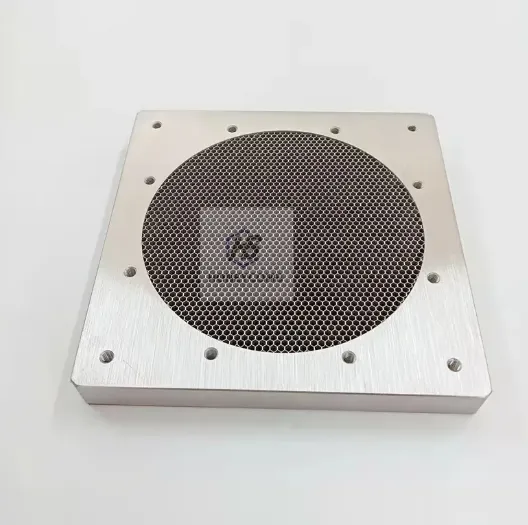

A: It uses internal vanes or honeycomb structures to align chaotic airflow into a laminar stream. This minimizes pressure loss and enhances measurement accuracy in ducts or pipes.

Q: Where is an intake air straightener (redresseur d'air d'admission) typically installed?

A: Installed upstream of critical components like sensors, turbines, or filters. Placement ensures optimized airflow before it reaches sensitive equipment.

Q: What materials are air straighteners made from?

A: Common materials include aluminum, stainless steel, or engineered plastics. Choices depend on temperature, corrosion resistance, and application requirements.

Q: Do air straighteners require regular maintenance?

A: Periodic inspection for debris or damage is recommended. Cleaning ensures consistent performance, but no frequent adjustments are typically needed.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025