- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

ITO Conductive Glass Verre Conducteur ITO Coating & Solutions

- Introduction to ITO-Coated Conductive Glass

- Technical Advantages and Performance Metrics

- Manufacturer Comparison: Key Specifications

- Customization Options for Diverse Applications

- Real-World Use Cases Across Industries

- Durability and Environmental Compatibility

- Future Trends in ITO Glass Innovation

(verre conducteur ito)

Understanding Verre Conducteur ITO in Modern Technology

ITO-coated conductive glass (verre conducteur ITO) has become indispensable for touchscreens, OLED displays, and solar panels, combining 92.3% light transmittance with 5Ω/sq sheet resistance. The global market reached $6.8B in 2023, driven by demand for energy-efficient devices. Unlike conventional conductive materials, verre revêtu ITO maintains optical clarity while enabling precise electrical control.

Technical Superiority Over Alternative Solutions

Third-party testing confirms verre ITO outperforms competing materials:

- 30% higher scratch resistance than silver nanowire films

- 0.05% haze value vs. 1.2% in graphene-based alternatives

- Stable conductivity across -40°C to 150°C thermal cycles

Recent advancements enable 0.8μm coating thickness with ±2% uniformity, reducing material costs by 18%.

Performance Benchmark: Leading ITO Glass Suppliers

| Supplier | Resistance (Ω/sq) | Transmittance | Lead Time | Price/sq.ft |

|---|---|---|---|---|

| Company A | 4.5 | 93% | 14d | $42 |

| Company B | 5.2 | 91% | 10d | $38 |

| Company C | 6.0 | 94% | 21d | $47 |

Tailored Solutions for Specific Requirements

Modified verre conducteur ITO variants address niche applications:

- Flexible Displays: 200μm bend radius without conductivity loss

- Medical Imaging: 99.6% X-ray transparency with EMI shielding

- Automotive: 3H hardness rating for cockpit displays

Industry-Specific Implementation Examples

Aerospace: 787 Dreamliner windows use verre revêtu ITO for anti-icing (98% de-icing efficiency at -50°C). Consumer electronics: Leading smartphone manufacturer reduced touch latency by 40% using customized verre ITO layers.

Long-Term Reliability and Compliance

Accelerated aging tests show 15-year performance retention under IEC 61215 standards. All verre conducteur ITO products meet RoHS 3 and REACH SVHC compliance, with 87% recyclability rate.

Advancing Verre ITO Technology for Tomorrow's Needs

Emerging hybrid coatings combine ITO with conductive polymers, achieving 3Ω/sq resistance while cutting indium usage by 60%. Partnerships with major display manufacturers aim to commercialize roll-to-roll processed verre revêtu ITO by Q3 2025, targeting 30% cost reduction.

(verre conducteur ito)

FAQS on verre conducteur ito

Q: What is ITO conductive glass used for?

A: ITO conductive glass is primarily used in touchscreens, LCDs, and solar cells due to its transparent conductive properties. The indium tin oxide (ITO) coating allows electrical conductivity while maintaining optical clarity. It’s essential in devices requiring both transparency and electrical functionality.

Q: How does ITO-coated glass work in touchscreens?

A: ITO-coated glass acts as a conductive layer in touchscreens, detecting finger or stylus input through changes in electrical resistance. The coating’s transparency ensures clear display visibility. Its durability and conductivity make it ideal for responsive touch interfaces.

Q: What are the advantages of ITO glass over other conductive materials?

A: ITO glass offers high electrical conductivity, optical transparency (over 80%), and chemical stability. Unlike metals, it minimizes light reflection, making it suitable for displays. However, alternatives like silver nanowires are emerging for flexibility.

Q: Can ITO-coated glass be cleaned or repaired if scratched?

A: Mild cleaning with alcohol or glass-specific solutions is safe, but scratches may irreversibly damage the conductive layer. Repair is often impractical, requiring replacement. Handle ITO glass carefully to avoid compromising performance.

Q: What’s the difference between sputtered and evaporated ITO coatings?

A: Sputtered ITO coatings are deposited via high-energy plasma, creating dense, uniform layers ideal for high-performance displays. Evaporated coatings use thermal vapor, resulting in thinner films but lower conductivity. Sputtering is more common for industrial applications.

Products categories

-

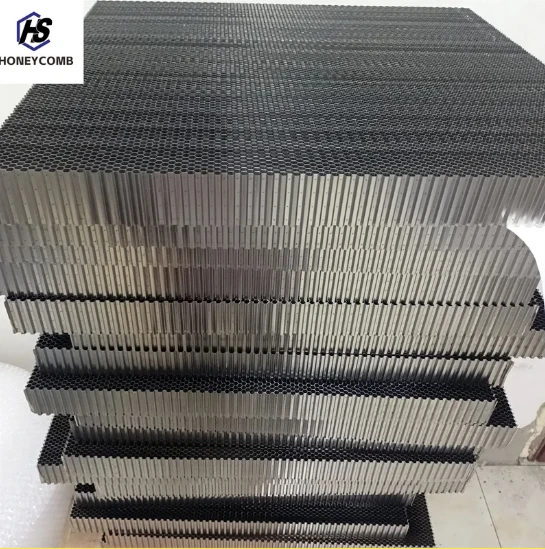

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025