Industry Trends: Transforming Fluid Dynamics with Wind Tunnel Honeycomb Solutions

The surge in demand for reliable, high-efficiency air flow control across automotive, hydropower, and process engineering sectors has propelled wind tunnel honeycomb, MAF straightener, and air straightener honeycomb to the technological forefront. According to MarketsAndMarkets, the global wind tunnel market is projected to grow at a CAGR of 4.3% from 2023 to 2028, driven by advancements in honeycomb core materials, precision manufacturing, and their vital role in automotive aerodynamics, aerospace research, petrochemicals, and architectural ventilation scenarios.

- Key drivers: energy-saving initiatives, stricter fluid test standards (ISO, ANSI/AMCA), customized specification adoption, emerging CFD-backed tunnel designs.

- Application Hotspots: Wind tunnels in automotive and aerospace labs, MAF (Mass Air Flow) sensors, HVAC systems, gas & water flow rectification, emission test benches, precision metrology, and corrosion-prone process plants.

Key Parameters and Specifications of Wind Tunnel Honeycomb

The performance of a wind tunnel honeycomb or air straightener honeycomb depends on its core geometry, material, cell size, wall thickness, manufacturing accuracy, and compliance with international standards. Here is a comparison of commonly adopted specifications and newer technological benchmarks.

| Parameter | Industry Standard | Advanced Spec (Hengshi) | Unit |

|---|---|---|---|

| Material | Aluminum 5052, SUS 201 | SUS 304 (Stainless Steel) | - |

| Cell Size (Aperture) | 3.2 - 25 mm | 3 mm - 18 mm (Custom) | mm |

| Wall Thickness | 0.06 - 0.15 mm | 0.07 - 0.20 mm | mm |

| Panel Thickness | 30 - 300 mm | 30 - 400 mm | mm |

| Cell Shape | Hexagonal, Square | Hex, Square, Triangle, Custom | - |

| Surface Finish | Mill, Anodized | Polished, Powder/Custom Coating | - |

| Standard Compliance | ISO 14644-15, ANSI/AMCA 210 | ISO 9001, ISO 14644-15, Custom QA | - |

| Corrosion Resistance | Basic | High (SUS 304) | - |

Chart: Market Share by Honeycomb Material (2023 Data)

Advanced wind tunnel honeycomb flow straighteners, particularly SUS 304 honeycomb cores, are now favored due to their high mechanical strength, corrosion resistance, long-term stability in acidic or wet environments, and ease of cleaning.

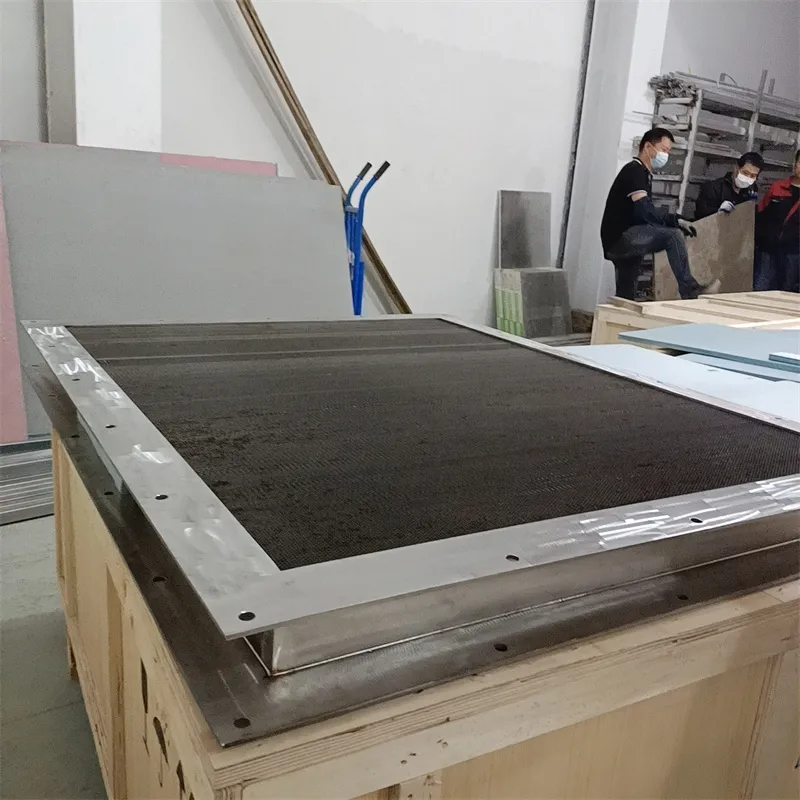

Case Spotlight & Product Benchmark: Hengshi Customized Diverse SUS 304 Honeycomb Air Flow Straightener

Hengshi delivers industry-leading air flow straighteners tailored for wind tunnel, MAF and critical flow applications. The featured product, Hengshi Customized Diverse SUS 304 Honeycomb Air Flow Straightener, stands out by:

- Employing premium SUS 304 for unmatched anti-corrosion and fatigue resistance.

- Supporting full customization (geometry, aperture, protective finish, dimensions).

- Manufactured per ISO 9001 and ISO 14644-15 clean flow requirements.

- Widely adopted in wind tunnels, MAF test rigs, thermal flow labs, chemical/petrochemical & energy plants.

- Passed third-party hydraulic/air flow tests verified by accredited laboratories.

| Feature | Hengshi SUS 304 Honeycomb | Generic Brand A | Generic Brand B (Aluminum) |

|---|---|---|---|

| Base Material | SUS 304 Stainless Steel | SUS 201 / Aluminum 5052 | Aluminum 5052 |

| Cell Size Range | 3–18 mm (custom) | 4–12 mm | 5, 9 mm |

| Wall Thickness | 0.07–0.20 mm | 0.08–0.15 mm | 0.08–0.12 mm |

| Panel Thickness | 30–400 mm | 30–250 mm | 30–180 mm |

| Standard Compliance | ISO 9001, ISO 14644-15 | Partial (internal QA only) | ANSI/AMCA 210 |

| Corrosion Resistance | ★★★★★ (Salt mist ISO9227, 1000h) | ★★★ | ★★ |

| Service Life (Ind. Use) | 12–15 years | 7–10 years | 5–9 years |

Technical Performance Comparison: Flow Uniformity by Cell Type

Manufacturing Process of Wind Tunnel Honeycomb: Flow, Arrows & Standards

The production of a high-performing wind tunnel honeycomb and air straightener honeycomb demands strict control over each stage, from material selection to surface treatment and final QC. Below, we detail the craft steps utilized by Hengshi in their advanced straightener line, highlighting critical quality checkpoints.

Premium SUS 304 Coils

Precision Cutting

±0.02 mm

Forming Hex Cell, High-Temp Welding

Size Trimming,

Panelization, Edge Framing

Polish/Coat,

Customized Request

Airflow, Flatness, Dim. Check

ISO 9001/14644

Material: High-grade SUS 304, strict batch traceability

Precision: CNC edge treatment, flatness error < 0.15 mm/m

Welding: Robotic spot or laser welding for zero cell deformation

Inspection: Pass/Fail per ISO14644-15, finish checked to Ra <=0.8 µm

Application Scenarios & Advantages: Wind Tunnel Honeycomb in Action

- Delivers turbulent intensity <0.5% in full-scale and model tunnels.

- Supports MAF sensor calibration per ISO 17205 (Euro6) and ASME PTC 19.5.

- Withstands daily test cycles over 10 years (certified durability).

- Corrosion-proof for desalination, chemical fume, or petroleum atmospheres (passed Salt Mist ISO9227).

- Saves 6–11% in fan energy with precise air flow straightening (Industry Test: China Shenhua 2023).

- Honeycomb straighteners with cell size 6–15 mm enable laminar flows at Reynolds numbers 12,000+

- Easy modular installation, compatible with flexible seals and custom frame.

Typical Industry Collaborations

- Global wind tunnel centers (Germany, USA, Korea, China) using Hengshi’s honeycomb grid in academic and OEM labs.

- Process equipment integration with Siemens, CNPC, Baowu Steel, CRRC for HVAC and exhaust test rigs.

Customized Solutions & Support

Hengshi provides custom engineering from initial CFD modeling, aperture mapping, to precision fabrication—tailoring cell size, thickness, panel geometry, and finishes to specific project needs in wind tunnels, emission lines, or harsh industry process flows.

| Spec Option | Range | Remarks |

|---|---|---|

| Cell Aperture | 3–25 mm | Hex/Square/Custom, tolerance ±0.03 mm |

| Panel Size | Up to 2000×1500 mm | Edge frame reinforced, modular design |

| Coating/Finish | Polished / Nickel-plated / Epoxy / None | Per client request (e.g., salt-alkali proof) |

| Shape | Hexagon / Square / Rectangular / Circular | For circular or duct mount tunnels |

| Mounting Style | Frame, Snap-fit, Bolt-in | Custom gaskets/seals available |

| Material Certification | EN 10204 3.1, RoHS, REACH | Full traceability |

Delivery, Quality & Support

- Lead Time: Standard modules: 5–8 working days; custom panels: 10–16 days + expedited freight.

- Warranty: 2-year defect-free guarantee, extended warranty available.

- Support: On-site installation guide, remote troubleshooting, free engineering consulting for CFD compatibility.

Product Performance at a Glance: Data Visualization

Analysis: Hengshi SUS 304 panels offer the lowest flow resistance, highest certified corrosion resistance, and cost-effectiveness over full life-cycle, significantly reducing total cost of operation for wind tunnel and process industry clients.

Professional FAQ: Expert Answers about Wind Tunnel Honeycomb & Air Straighteners

1. What is the optimal cell size for wind tunnel honeycomb panel?

2. Why is SUS 304 considered superior for air straightener honeycomb?

3. How are mounting standards for honeycomb panels defined?

4. What testing is performed before delivery?

- Flatness and dimensional accuracy check (±0.1 mm).

- Corrosion resistance: Neutral Salt Mist ISO9227 (>1000 hours).

- Air or water flow uniformity (per ISO/ASME lab benchmarks).

- Material traceability report EN10204-3.1.

5. Are custom geometries (inclined, circular, segmented) supported?

6. What is the typical service life and warranty?

7. How quickly can a wind tunnel honeycomb be delivered?

Conclusion & Further Reading

The wind tunnel honeycomb, MAF straightener, and air straightener honeycomb market is evolving swiftly with demands for higher accuracy, durability, and regulatory compliance. Hengshi’s SUS 304 air flow straighteners exemplify the new gold standard, trusted by advanced wind tunnels, process giants, and research institutes globally. With best-in-class technical parameters and proven service track record, they help unlock next-level lab and industrial performance.

References & Authority Sources

- MarketsandMarkets: Wind Tunnel Market Report 2023-2028

- AMCA International: ANSI/AMCA 210 Laboratory Air Flow Testing Standards

- Engineering StackExchange: Wind Tunnel Laminar Straightener Cell Size Selection

- ResearchGate: Manufacturing and Performance of Honeycomb Laminar Flow Straighteners

- ASME PTC 19.5: Test Code for Wind Tunnel Measurement [ASME Standard]