Honeycomb Stainless Steel Air Flow Straightener - Hengshi|Airflow Stabilization, Turbulence Reduction

Product Introduction

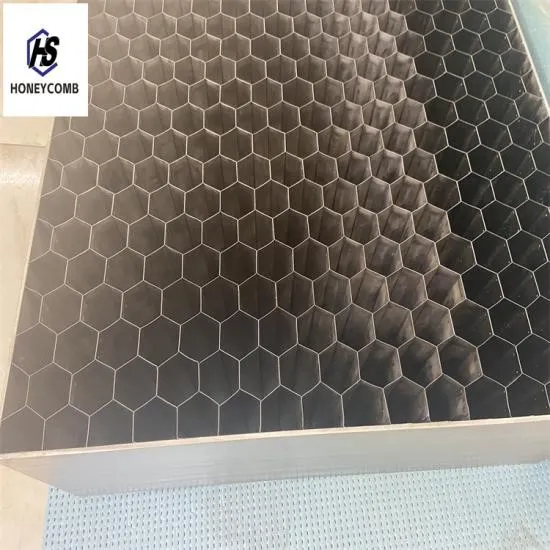

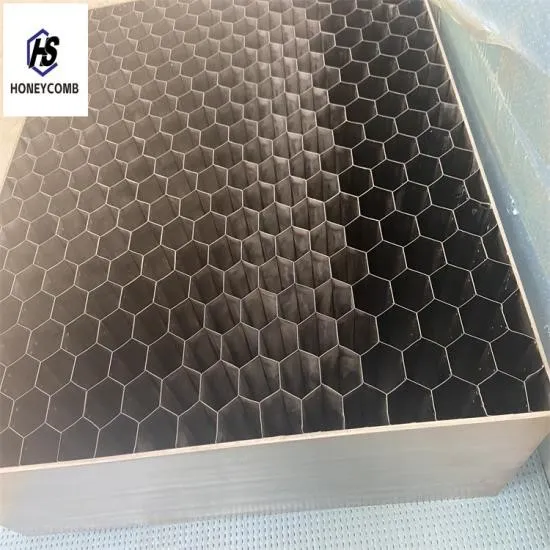

The Honeycomb Stainless Steel Air Flow Straightener represents a pinnacle of engineering excellence in aerodynamic research and industrial applications. This innovative product, developed by Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd., leverages the proven efficiency of honeycomb structures to stabilize airflow and enhance measurement accuracy in critical environments. The Steel Honeycomb Wind Tunnel further extends this technology, offering a reliable solution for aerodynamic testing across multiple industries.

Core Features and Advantages

At the heart of the Honeycomb Air Flow Straightener lies its unique design, which transforms turbulent airflow into laminar flow. This is achieved through a network of thin cell walls that create straight passageways with a maximum open area of 95-99%. This design minimizes pressure drop while reducing turbulence, ensuring precise measurements in demanding applications. The product's versatility is further enhanced by its compatibility with a wide range of materials, including 304 stainless steel, 316L, and other high-performance alloys.

Key advantages of this technology include:

- High Shielding Effectiveness: Ideal for electromagnetic interference (EMI) shielding in sensitive environments.

- Corrosion Resistance: Stainless steel construction ensures durability in harsh conditions.

- Excellent Sound Insulation: Reduces noise pollution in industrial settings.

- Optimal Ventilation: Enhances airflow efficiency for cooling and pressure regulation.

Technical Specifications

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper, etc. |

|---|---|

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, 6.0, 8, 10, 12, 20, 30 mm (customizable) |

| Thickness | Customized |

| Surface Treatment | Painting, white oxygen, Electroless Nickel plating, electrophoresis, powder coating, Brush (as required) |

| Certifications | ISO9001, RoHS |

| Welding Technology | Spot welding, vacuum brazing |

| Applications | EMI shielding vent, flow straightener, railways, marine, aviation & aerospace, wind energy, defense, gas seals, communications, medical, etc. |

Applications in Aerodynamic Research

The Honeycomb Air Flow Straightener is a critical component in wind tunnel systems, which are essential for studying aerodynamic effects. According to the National Institute of Standards and Technology (NIST), wind tunnels are indispensable tools for testing the performance of vehicles, structures, and machinery under controlled airflow conditions [1]. These systems are used to analyze air resistance, heat resistance, and pressure resistance in applications ranging from automobiles and aircraft to high-speed trains and ships.

Key applications include:

- Aircraft and Missile Design: Ensuring aerodynamic efficiency and stability during flight.

- Automotive Engineering: Optimizing vehicle aerodynamics to improve fuel efficiency and performance.

- Marine and Rail Transport: Testing hydrodynamic and aerodynamic properties of ships and trains.

- Renewable Energy: Evaluating wind turbine blade performance in controlled environments.

Company Background: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

As a leading manufacturer in the field of high-quality shielding products, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. has established itself as a trusted provider of steel honeycomb cores, honeycomb air flow straighteners, and honeycomb seals. The company's commitment to innovation and quality is reflected in its ISO9001 and RoHS certifications, ensuring compliance with global standards for manufacturing excellence.

Hengshi's expertise extends to custom solutions tailored for industries such as aerospace, defense, and medical technology. Their ability to produce customized honeycomb structures with precise dimensions and surface treatments underscores their adaptability to diverse client needs.

Conclusion

The Honeycomb Stainless Steel Air Flow Straightener and Steel Honeycomb Wind Tunnel exemplify the intersection of engineering precision and industrial application. With their ability to enhance airflow accuracy, reduce turbulence, and withstand harsh environments, these products are indispensable in modern aerodynamic research and industrial processes. By partnering with Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd., clients gain access to cutting-edge solutions backed by rigorous quality standards and a legacy of innovation.

References

[1] National Institute of Standards and Technology (NIST). "Wind Tunnel Testing and Aerodynamic Research." Retrieved from https://www.nist.gov.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025