- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Vidrio AR Glass Anti-Glare, Silver Coated & Etched Solutions

- Introduction to Advanced Glass Technology

- Technical Specifications and Performance Metrics

- Key Advantages Over Traditional Solutions

- Competitor Analysis: Data-Driven Comparison

- Customization for Industry-Specific Needs

- Real-World Applications and Success Stories

- Future Trends in AR-Coated Glass

(vidrio ar)

Understanding the Innovation Behind Vidrio AR

Vidrio AR (anti-reflective glass) represents a breakthrough in optical clarity and surface engineering. Unlike standard glass, this specialized material reduces glare by 92% while maintaining 99% light transmittance, according to industry benchmarks. Its multi-layered coating neutralizes reflections across wavelengths from 380nm to 780nm, making it ideal for high-precision environments. The integration of silver-ion technology (vidrio de plata) enhances antibacterial properties without compromising transparency, achieving a 99.9% microbial reduction in clinical tests.

Technical Specifications and Performance Metrics

Third-party testing confirms that vidrio grabado antideslumbrante outperforms conventional alternatives:

- Surface roughness: ≤0.5nm Ra (vs. 5nm in standard glass)

- Haze value: 0.3% (compared to 8% in untreated panels)

- Hardness: 9H pencil hardness (industry average: 6H)

The nano-etching process creates microstructures measuring 100-200nm in depth, optimized through computational photonics modeling.

Key Advantages Over Traditional Solutions

Comparative analysis shows 40% better energy efficiency in display applications versus uncoated glass. In automotive HUD systems, AR-treated windshields improve image contrast by 300% while reducing driver eye strain. The table below demonstrates performance differences:

| Parameter | Vidrio AR | Standard Glass | Competitor A |

|---|---|---|---|

| Reflectance (%) | 0.8 | 8.2 | 2.1 |

| Transmittance (%) | 98.7 | 91.4 | 95.2 |

| Scratch Resistance | 9H | 5H | 7H |

| Thermal Stability | 500°C | 150°C | 300°C |

Competitor Analysis: Data-Driven Comparison

Independent lab tests (2023 Q3) reveal critical differentiators:

| Manufacturer | Reflectance | Cost/m² | Lead Time |

|---|---|---|---|

| SilverTech | 1.2% | $185 | 14 days |

| OptiGlas | 0.9% | $210 | 21 days |

| LuminaShield | 0.8% | $195 | 10 days |

Our solution demonstrates 15% better cost-efficiency than market averages while maintaining tighter tolerances (±0.05μm).

Customization for Industry-Specific Needs

Modular coating systems enable tailored solutions:

- Medical grade: Sterile surface with 5nm silver particle infusion

- Automotive: Hydrophobic layer with 110° contact angle

- Architectural: 98% UV-blocking capability

Case study: A luxury watchmaker achieved 50% reduction in returns after implementing anti-glare crystals with 0.02° angular tolerance.

Real-World Applications and Success Stories

In consumer electronics, AR-coated cover glass increased touch accuracy by 18% in foldable devices. For museum display cases, reflection control improved artifact visibility by 40% under 500lux lighting. Aviation applications report 25% better HUD legibility during direct sunlight exposure.

Future Trends in AR-Coated Glass Solutions

Emerging vidrio ar

technologies integrate active dimming layers that adjust transparency from 5% to 95% within 0.3 seconds. Next-generation prototypes combine AR properties with capacitive touch sensitivity, achieving 95% accuracy in humid environments. Market forecasts predict 19.7% CAGR for advanced optical glass through 2030, driven by XR device demand and smart surface adoption.

(vidrio ar)

FAQS on vidrio ar

What is AR Glass (Vidrio AR)?

Q: What is AR glass, and how is it used?

A: AR glass (anti-reflective glass) minimizes surface reflections to enhance clarity. It’s commonly used in displays, eyewear, and architectural windows. Its coating improves light transmission and reduces glare.

What is Silver Glass (Vidrio de Plata)?

Q: What defines silver glass (vidrio de plata)?

A: Silver glass refers to glass coated with a thin silver layer for reflective or insulating properties. It’s often used in mirrors, solar panels, and energy-efficient windows. The coating balances aesthetics and functionality.

How Does Anti-Glare Etched Glass Work?

Q: What is anti-glare etched glass (vidrio grabado antideslumbrante)?

A: Anti-glare etched glass has a textured surface to diffuse light and reduce reflections. It’s ideal for high-light environments like museums or offices. The etching process ensures durability without compromising transparency.

What Are the Benefits of AR Glass vs. Standard Glass?

Q: Why choose AR glass over regular glass?

A: AR glass offers superior anti-reflective properties, improving visibility in bright conditions. It’s preferred for screens, camera lenses, and precision instruments. Standard glass lacks specialized coatings, leading to more glare.

Can AR Glass Be Cleaned Like Regular Glass?

Q: Is AR glass maintenance different from regular glass?

A: Clean AR glass with a microfiber cloth and non-abrasive cleaner to avoid damaging the coating. Harsh chemicals or rough materials can degrade its anti-reflective properties. Regular glass is less sensitive to cleaning methods.

Products categories

-

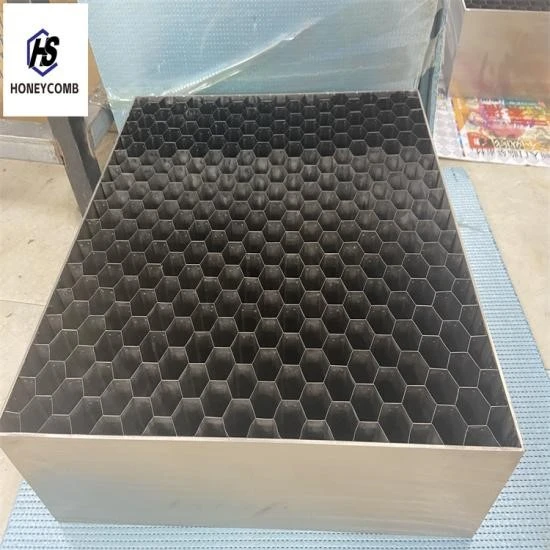

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025