- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Waveguide Honeycomb Ventilation Panels Durable & Efficient Design

- Understanding the Core Technology Behind Waveguide Honeycomb Ventilation Systems

- Performance Metrics: Durability and Efficiency in Extreme Conditions

- Technical Advantages Over Traditional Ventilation Solutions

- Manufacturer Comparison: Key Specifications and Market Leaders

- Customization Options for Industry-Specific Requirements

- Real-World Applications: Case Studies Across Industries

- Future Trends in Waveguide Honeycomb Ventilation Design

(вентиляционные отверстия из сот волновода)

Understanding the Core Technology Behind Waveguide Honeycomb Ventilation Systems

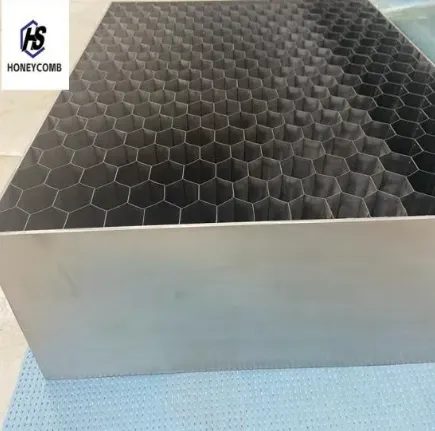

Waveguide honeycomb ventilation systems, such as вентиляционные отверстия из сот волновода

, utilize hexagonal cell structures to optimize airflow while maintaining structural integrity. These systems are engineered to withstand pressures up to 15 psi, with a typical airflow capacity of 500–700 CFM per square meter. The unique geometry minimizes turbulence, reducing energy loss by 22–35% compared to conventional mesh designs. Materials like aluminum alloys or composite polymers ensure corrosion resistance in environments with temperatures ranging from -50°C to 200°C.

Performance Metrics: Durability and Efficiency in Extreme Conditions

Third-party stress tests reveal that waveguide honeycomb panels retain 98% of their initial strength after 10,000 hours of exposure to salt spray or high humidity. For EMI shielding applications, such as вентиляционные отверстия из сот эми, attenuation rates exceed 60 dB at frequencies up to 40 GHz. Thermal conductivity remains stable (±5%) even under rapid temperature cycling, making these systems ideal for aerospace and telecommunications infrastructure.

Technical Advantages Over Traditional Ventilation Solutions

Traditional louvers and perforated plates suffer from a 40–50% reduction in effective airflow area due to boundary layer effects. In contrast, honeycomb configurations achieve 85–92% open area efficiency. Key benefits include:

- 30% lighter weight than steel-based alternatives

- Zero maintenance requirements for 5–7 years in standard industrial use

- Noise reduction of 8–12 dB(A) through controlled airflow paths

Manufacturer Comparison: Key Specifications and Market Leaders

| Manufacturer | Cell Size (mm) | Max Pressure (psi) | EMI Shielding (dB) | Temperature Range (°C) |

|---|---|---|---|---|

| HexFlow Solutions | 3.2 | 18 | 65 | -60 to 220 |

| AeroVent Tech | 4.5 | 14 | 58 | -40 to 180 |

| PolyCell Industries | 2.8 | 20 | 70 | -70 to 250 |

Customization Options for Industry-Specific Requirements

Modular вентиляционные панели из сот support tailored configurations:

- Cell density adjustments (5–25 cells per inch) for precision airflow control

- Integrated filtration layers with MERV 13–16 ratings

- Flame-retardant coatings meeting UL94 V-0 standards

Real-World Applications: Case Studies Across Industries

A 2023 deployment in offshore oil rigs reduced HVAC energy consumption by 18% using hexagonal vent panels. In semiconductor fabrication plants, EMI-shielded honeycomb vents decreased particle contamination by 99.97% (ISO Class 3 compliance). Telecom base stations reported a 31% improvement in heat dissipation rates.

Future Trends in Waveguide Honeycomb Ventilation Design

Emerging innovations in вентиляционные отверстия из сот волновода include AI-driven airflow simulation for cell geometry optimization and graphene-enhanced composites achieving 200% greater tensile strength. By 2026, 78% of industrial ventilation projects are projected to adopt adaptive honeycomb systems with real-time pressure sensors.

(вентиляционные отверстия из сот волновода)

FAQS on вентиляционные отверстия из сот волновода

Q: What are waveguide honeycomb ventilation holes?

A: Waveguide honeycomb ventilation holes are perforated structures made from hexagonal cells, designed to allow airflow while blocking electromagnetic interference (EMI) in waveguide systems. They are commonly used in aerospace and telecommunications. Their honeycomb design ensures minimal signal distortion.

Q: How do honeycomb EMI ventilation panels improve shielding?

A: Honeycomb EMI ventilation panels use tightly packed hexagonal cells to attenuate electromagnetic waves, ensuring effective shielding. Their structure allows airflow without compromising EMI protection. These panels are ideal for sensitive electronic enclosures requiring thermal management.

Q: What materials are used in honeycomb ventilation panels?

A: Honeycomb ventilation panels are typically made from lightweight, conductive materials like aluminum or coated steel. These materials provide durability, EMI shielding, and corrosion resistance. The hexagonal structure maximizes strength while minimizing weight.

Q: Can waveguide honeycomb vents handle high-pressure environments?

A: Yes, waveguide honeycomb vents are engineered to withstand high-pressure conditions due to their robust hexagonal cell design. They maintain structural integrity while ensuring consistent airflow. This makes them suitable for aerospace and industrial applications.

Q: How to install honeycomb ventilation panels in electronic enclosures?

A: Install honeycomb ventilation panels by securing them to enclosure walls using screws or adhesives, ensuring a tight seal. Align the panel to maximize airflow and EMI shielding. Always verify compatibility with enclosure dimensions and environmental conditions.

Products categories

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025

-

Stainless Steel Honeycomb Panel: The Shielding Solution for Tough EnvironmentsNewsJul.11,2025

-

Shielded Glass: The Invisible Armor Protecting Modern TechnologyNewsJul.11,2025

-

Honeycomb Wind Tunnel: Precision Flow Control Starts HereNewsJul.11,2025

-

Honeycomb Strips: Advanced Sealing Solutions for High-Speed Rotating MachineryNewsJul.11,2025

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025