- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

The Importance of Honeycomb Wind Tunnel

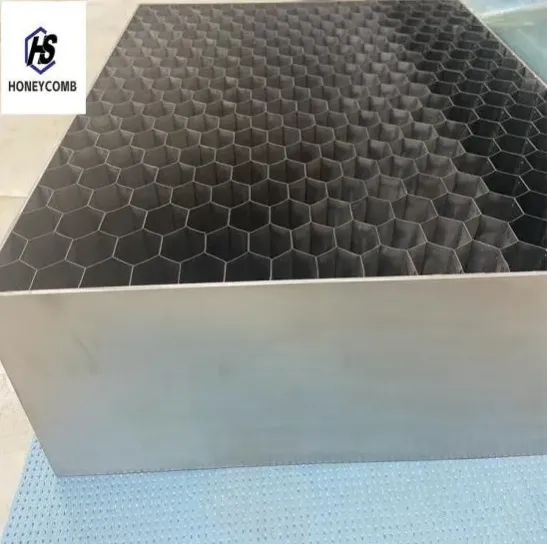

O Túnel de vento em favo de mel, as an important experimental equipment, plays a crucial role in fluid mechanics research, aerospace engineering, and other related fields. Its unique design, especially the use of honeycomb structures, enables it to generate high-quality, low turbulence airflow, providing the necessary foundation for precise experimental measurements and simulations. This article will explore the importance of favo de mel em túnel de vento from three aspects: airflow quality, experimental accuracy, and application scope.

The most important advantage of Honeycomb Wind Tunnel is its ability to significantly improve the quality of airflow

Traditional wind tunnels often have high turbulence levels, which are mainly caused by factors such as fans, contraction sections, and wall boundary layers. High turbulence intensity can affect the accuracy of experimental results, making it difficult for researchers to obtain reliable data. The function of honeycomb structure is to divide the airflow into a large number of small units, forcing the airflow to pass through these small channels. During this process, the lateral turbulent motion is effectively suppressed, thereby reducing the turbulence level of the airflow and making it tend towards uniformity and stability. This low turbulence airflow is crucial for studying boundary layer flow, airfoil aerodynamic characteristics, and aircraft stability.

The high-quality Honeycomb Wind Tunnel directly improves the accuracy of experiments

In precise fluid mechanics experiments, a stable and controllable airflow environment is essential. The uniform airflow provided by Wind Tunnel Honeycomb Design reduces measurement errors, allowing researchers to more accurately evaluate the performance of experimental models. For example, in airfoil experiments, low turbulence airflow can more clearly reveal the lift and drag characteristics of the airfoil, providing a more reliable basis for airfoil design. In addition, for experiments that require high-precision numerical simulation verification, a high-quality airflow environment can ensure better matching between experimental results and simulation results, thereby verifying the reliability of the numerical model.

The application range of Honeycomb Wind Tunnel is very wide

In addition to traditional aerospace fields such as aircraft design and aerodynamic performance evaluation, HVAC air flow straighteners are also widely used in the automotive industry, construction engineering, and environmental science. In the automotive industry, Honeycomb Wind Tunnel is used to optimize car exterior design, reduce air resistance, and improve fuel efficiency. In construction engineering, it can simulate the wind field around buildings, evaluate their wind resistance performance, and optimize ventilation system design. In the field of environmental science, it can be used to study the diffusion law of air pollution and provide scientific basis for formulating environmental protection measures.

In summary, the Air Straightener Honeycomb, with its excellent airflow quality control capabilities, has significantly improved experimental accuracy and played an important role in multiple fields. With the continuous development of science and technology, we have reason to believe that diy air fow straightener will play an increasingly important role in future fluid mechanics research and engineering practice.

Honeycomb Wind Tunnel FAQ

What is the core function of Honeycomb Wind Tunnel?

The Honeycomb Wind Tunnel installs a Honeycomb Flow Straightener at the airflow inlet to make the airflow more uniform and stable. Its main functions are:

Reduce turbulence and improve airflow quality;

Correct the direction of airflow to avoid deviation;

Improve testing accuracy and ensure the reliability of wind tunnel experimental data.

What are the key parameters for the structural design of honeycomb devices?

The performance of a cellular device depends on:

Honeycomb shape (hexagonal is optimal, circular/rectangular is easier to process);

Length to diameter ratio (L/D) (usually 6:1-10:1, the longer the rectification effect, the better, but the voltage drop increases);

Materials (aluminum, stainless steel or composite materials, affecting corrosion resistance and lifespan).

What applications is Honeycomb Wind Tunnel suitable for?

Mainly used for:

Aerospace (aircraft, missile aerodynamic testing);

Automotive industry (optimizing body drag, such as F1 racing wind tunnel);

Building wind engineering (evaluating the wind resistance performance of high-rise buildings);

Scientific research experiment (fundamental research in fluid mechanics).

What are the advantages of Honeycomb Wind Tunnel compared to ordinary wind tunnels?

More stable airflow (lower turbulence, more accurate data);

Suitable for high-precision testing (such as laminar flow research in low-speed wind tunnels);

Stronger adaptability (adjustable honeycomb structure to meet different experimental needs).

What should be noted for the maintenance of Honeycomb Wind Tunnel?

Regular cleaning (to avoid honeycomb blockage affecting airflow);

Check the structural integrity (to prevent deformation or corrosion);

Used in conjunction with damping mesh to further enhance airflow uniformity.

Categorias de produtos

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNotíciasJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNotíciasJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNotíciasJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNotíciasJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNotíciasJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNotíciasJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNotíciasJul.11,2025